Precision Stamping For Aluminum

Aluminum is highly machinable and relatively inexpensive, making it perfect for Precision Stamping. Manufacturers can stamping it three or even four times faster than other common sheet materials such as stainless steel and steel.Its flexibility and impressive strength-to-weight ratio make it ideal for use as the exterior skin panels of all forms of transportation, from automobiles and trains to aircraft and boats.

Greater emphasis on fuel efficiency and “lightweighting” has seen aluminum replace the heavier metals traditionally used to make components and internal structures. Its high corrosion resistance also avoids the need for heavy and expensive anti-corrosion coatings often required by other materials.

Additionally, aluminum is non-toxic, malleable and 100% recyclable. This is why the metal is so widely used for food and drink containers, trays, lids, sachets, pouches and wrappers.Thanks to its sleek, silver surface finish, it is also well-suited for electronic devices like smartphones, laptops, tablets, and flatscreen TVs.

It can even be found in construction projects both as a design feature and to provide structural support.Put all these characteristics together and you have a material that is lighter than steel, stronger and more reliable than plastic, inexpensive, readily available and infinitely adaptable.

As lightweight metals are widely used, aluminum stamping parts are becoming a choice of many industries. With all of our precision fabrication experience, stamping aluminum has been Be-cu.com(Pintejin Group)’s expertise for many years.

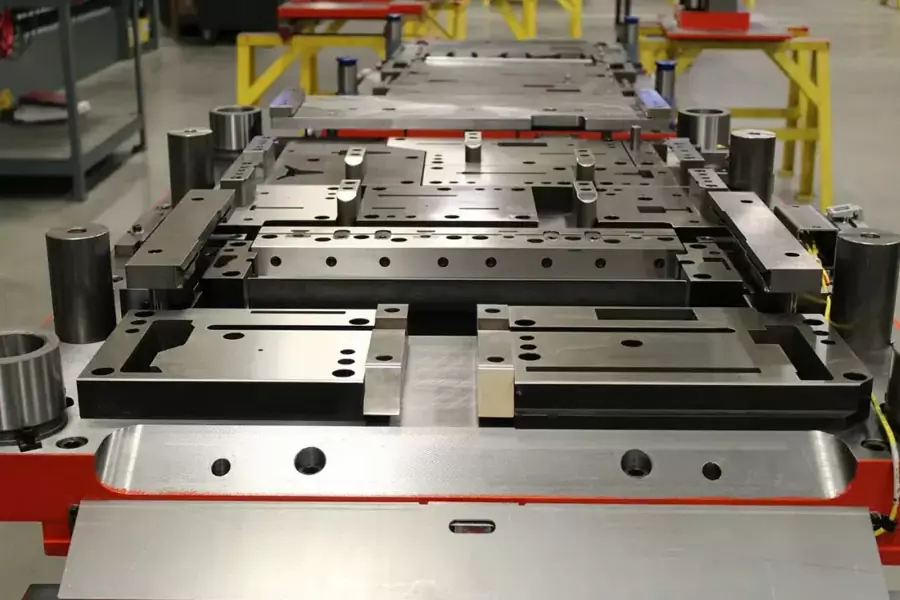

We focus on the manufacturing of non-standard precision aluminum high speed stamping parts with complex structures and are committed to delivering high accuracy and consistent components to our clients. We continue to invest in new stamping equipment and skilled employees to ensure that our team maintains a strong competitive advantage. We have also been improving the aluminum stamping and mold making process to improve efficiency and quality, and continue to meet customer production needs.

The Aluminium And Aluminum Alloy Grades Of Precision Stamping

But just because high speed punching machine simplify aluminum stamping, it doesn’t mean fabricating aluminum parts is any less complex than it used to be. There are many aluminum grades (or alloys) available in the market today, and the success of your project will depend on you choosing the most suitable aluminum alloy for your project. Common examples of aluminum stamping grades include:

- The 1000 series is the series with the most aluminum content among all series. The purity can reach more than 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is currently the most commonly used series in conventional industries. Most of the products circulating in the market are 1050 and 1060 series.

- The 2000 series aluminum is characterized by high hardness, among which the copper content is the highest, about 3-5%. The 2000 series aluminum plates are aviation aluminum materials and are not often used in conventional industries.

- The 3000 series aluminum can also be called anti-rust aluminum. It is made of manganese as the main component and the content is between 1.0-1.5%. It is a series with better anti-rust function.

- The 4000 series aluminum plates belong to the series with higher silicon content. Usually the silicon content is between 4.5-6.0%. It belongs to construction materials, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance. Product description : It has the characteristics of heat resistance and wear resistance.

- The 5000 series aluminum plate belongs to the more commonly used alloy aluminum plate series, the main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy. The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series. Therefore, it is commonly used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries.

- The 6000 series aluminum sheet: stands for 6061. It mainly contains two elements: magnesium and silicon. 6061 is a cold-treated aluminum forged product, suitable for applications with high requirements for corrosion resistance and oxidation. Good workability, excellent interface characteristics, easy coating, and good processability.

- The 7000 series aluminum plate belongs to the aviation series. It is an aluminum-magnesium-zinc-copper alloy and a heat-treatable alloy. It is a super hard aluminum alloy with good wear resistance.

- The 8000 series is an aluminum plate whose main function is to make bottle caps. It is also used in radiators, most of which are aluminum foil.

Due to its low cost and formability, 1100 aluminum,3003 Aluminum and 5052 Aluminum common used for Be-cu’stamping projects.Be-cu also provides aluminum metal stamping using more specialized alloys including 6061, 6063, 2024, 7075, and many others. We can help you select the right aluminum alloy based on your project requirements. Considerations include formability, weldability, heat treating, machining, desired levels of strength and corrosion resistance, heat treating and more.

Aluminum Stamping Services – Precision Stamping For Aluminum

we Pintejin Group offer professional Precision Aluminum Stamping service (Punch) that is processes including of deep drawing,punching and blanking,progressive stamping,high speed stamping and fine blanking,anodizing surface treatment, to make any custom design parts with high-precision dimension.

Our Aluminum Stamping service and stamping mold making helps global customers to manage their operations and custom parts more efficiently. We have rich experience engineers to reduce labor & machining costs by cutting out time-consuming manual tasks and automating repetitive tasks, that helps to improve profit margin and save lead time for our valuable customers.

Our Aluminum Stamping service is not just limited to large volume orders, it’s no MOQ to produce small order(It can be manufactured by laser cutting, stretching, sheet metal and other processes) which start from 1 pcs as fast as 3 days.

- Connectors

- Bushings

- Panels

- Grilles

- End rings

- Collars

- Brackets

- Heat sinks

- Housings

- Adaptors

- Trays

- Cookware

- Rigging

- Flatware

- Plates

- Guttering

- Sleeves

- Appliances

- Fasteners

- Spacers

- Plugs

- Covers

- Pans

- Fittings

Stamped aluminum components are also used in furniture, chemical handling, ramps, safety railings, wheelchairs, hardware and more.

The Advantage Of Aluminum Stamping

Metal Stamping offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, aluminum stamping tools are typically 30% of the cost.

- Shorter Lead Times – The aluminum Stamping process amounts to significantly shorter turnaround times – tools and stamping components can be available within weeks rather than months.

- Maximum Design Flexibility – aluminum Stamping mold can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – aluminum stamping produces smooth, durable objects without seams or sheet metal, for parts require feature superior strength and great aesthetics.

Manufacturing Of Custom Aluminum Stamping Parts

If you need assistance on your custom aluminum Stamping projects, we will be one of the most capable and affordable production sources with our technology, experience, and skills. Our strict implementation of ISO9001 quality system standards, and the combination of efficient production processes and flexible custom engineering enable us to deliver complex projects in short turnaround times and provide excellent product quality.

Our Parts Case Studies Gallery Of Aluminum Stamping

We perform an efficient, accurate, and cost-effective process in-house to provide superior product results for your aluminum stamping.Whether you require punching aluminum pieces or custom aluminum parts for your automotive, aerospace applications or medical device component, we can easily help you. With our expertise in precision aluminum stamping and the ability to integrate external combined processes, we can ensure the best performance for your stamping aluminum projects.

-

Stamping Motor Vehicle Connection Plate Assembly

-

Car Fuel Tank Strap With Aluminum Stamping

-

Stamping Car Front Cross Member Front Housing

-

Precision Stamping Automotive Sink Reinforcement Plates

-

Precision Stamping Hood Left Hinge Attachment Plate

-

Aluminum Blanks Via Precision Stamping

-

Aluminum Deep Drawing Medical LED Display Enclosure