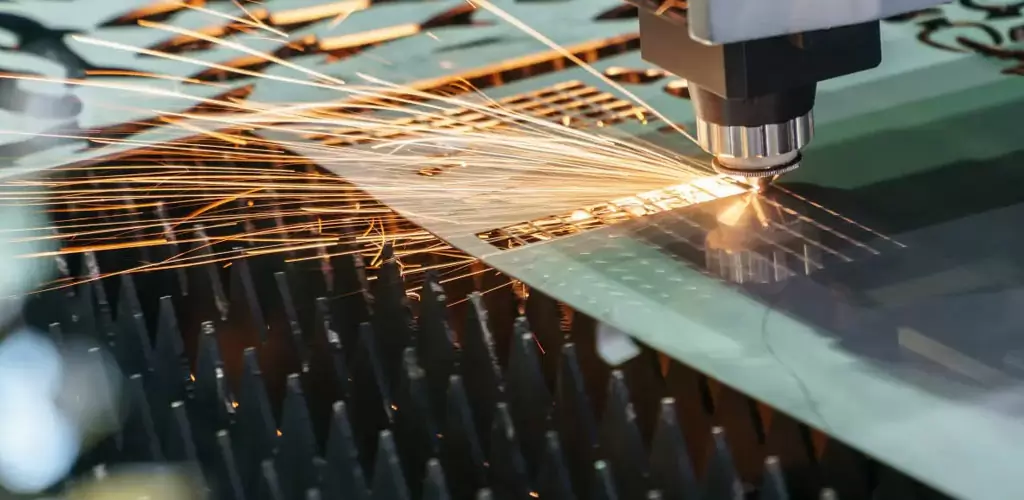

Aluminum Laser Cutting

Aluminum laser cutting is a parts fabrication method that uses a high energy density laser beam as a “cutting tool” to thermally cut aluminum and aluminum alloys.Due to its low melting point, high thermal conductivity, and especially low laser absorption, pure aluminum is more difficult to cut than iron-based metals.

Because aluminum alloy contains other alloying elements, the absorption rate of laser light in solid state is improved, which is easier to cut than pure aluminum, and the thickness and speed of cutting are also slightly larger. At present, aluminum and aluminum alloys are usually cut by fiber laser or pulsed laser. –

Laser cutting is that the horizontal laser beam emitted by the laser is transformed into a vertical downward laser beam through a 45° total reflection mirror, and then focused by a lens to form a very small spot at the focal point, and the laser power density is focused at the spot. Up to 10^6~10^9Wcm^2. The aluminum part at its focal point is irradiated by a high-power density laser spot, which will generate a local high temperature above 10,000°C, which will instantly vaporize the aluminum part, and then cooperate with the auxiliary cutting gas to blow away the vaporized metal, thereby cutting the aluminum part through A small hole is formed. With the movement of the CNC machine tool, countless small holes are connected to form the shape to be cut. Since the frequency of laser cutting is very high, the connection of each small hole is very smooth, and the cut aluminum alloy product has a high finish.

The Aluminium And Aluminum Alloy Grades Of Metal Laser Cutting

Aluminum is a malleable metal known for its significantly low density and high corrosion resistance, making it ideal for a range of applications within the construction, transportation, and aerospace industries.Aluminum laser cutting sheet or pipe is available in different grades depending on the application of the finished product. Common examples of aluminum laser cutting grades include:

| Aluminum Grade | Alloying Elements | Strengthening Process | Cracking | Corrosion Resistance | Finishing | Joining |

|---|---|---|---|---|---|---|

| 1xx.x | unalloyed | Non-heat-treatable | – | 1 | 1 | 1 |

| 2xx.x | Copper | Heat-treatable | 4 | 4 | 1-3 | 2-4 |

| 3xx.x | Silicon, Magnesium, Copper | Heat-treatable | 1-2 | 2-3 | 3-4 | 1-3 |

| 4xx.x | Silicon | Heat-treatable | 1 | 2-3 | 4-5 | 1 |

| 5xx.x | Magnesium | Non-heat-treatable | 4 | 2 | 1-2 | 3 |

| 6xx.x | NOT USED | NOT USED | – | – | – | – |

| 7xx.x | Zinc | Heat-treatable | 4 | 4 | 1-2 | 4 |

| 8xx.x | Tin, Copper, Nickel | Heat-treatable | 5 | 5 | 3 | 5 |

Aluminum Laser Cutting Services – CNC Laser Cutting Aluminum Parts Suppliers & Manufacturer

Need to cutting top-quality aluminum parts in a hurry? Want professional help with executing even the most complex manufacturing projects? Then Be-cu.com can help. We have years of experience in servicing a wide range of industries that have impeccable quality requirements for aluminum laser cutting parts, and can handle even the most challenging manufacturing tasks with ease. Our team of specialists will guide you through the entire process and ensure that you take advantage of the numerous aluminum laser cutting services benefits that the technology can offer.Be-cu.com chooses a high-power laser generation system, according to the graphics designed in the computer and with professional laser cutting software, the focused laser is irradiated on the surface of the aluminum plate and moves with the direction of the machine tool, so as to achieve cutting principle. The main feature of aluminum laser cutting is that it can cut very complex graphics, and the cutting cost is low. Because it is non-contact cutting, the deformation of the workpiece is small and the product quality is good.

Our Aluminum Laser Cutting Capabilities

At Be-cu.com, we can use our Feiyue series or Trulaser Machine to make clean, accurate cuts in aluminum sheets, utilizing all of the advantages shown above. We can fabricate parts from materials like 5052 ,6061 aluminum alloys and more aluminum alloys, and our laser will cut through them up to 1.5 inches thick.

Our machine uses a fiber laser, which is fast and energy-efficient when compared to other types of laser cutting. With this, we can cut any shape, no matter how complex. All we need to do is upload the schematic, and our CNC machine will take care of the rest.

Be-cu is a leading metal cutting service with over 30 years of experience serving a range of clients such as huawei, SAE Aviation, and FOURS Systems. If you want to know how we can help you, or if you just have some questions, click here to contact us today.

Why Use Our Aluminum Laser Cutting Services

The Top 6 Reasons:

- No MOQ:One-off aluminum laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom aluminum sheet metal fabrication technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Combine With Other Aluminum Manufacturing Processes

Most laser shops will only give quotations for laser cutting as a standalone process. But when the quantity of new parts goes up to hundreds or more, you need a better solution for the best results. For some of these conplex parts, it is better not to cut them from a solid block at all, but to use tool-based fabrication or edm cutting assisted by milling.

When making aluminum cutting parts, Be-cu.com offers several ways to combine precision laser cutting with other manufacturing processes in order to create more complex parts that can be made in large quantities. These process combinations can maximize the functionality of aluminum while still enjoying the benefits of other production processes.

CNC Bending,Welding, Laser Engraving, Metal Etching,Precision machining, stamping, EDM, Wire Cutting and more can all be complemented with laser cutting to make better aluminum components. No matter the test and no matter what properties are required.

Our Case Studies Gallery Of Aluminum Laser Cutting

Aluminum laser cutting produces durable, end-use aluminum parts with a wide selection of aluminum materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy, robotics and more.Compared with traditional laser cutting companies, we have a large amount of precision machines, so we can do precision post-machining in house.Send your CAD files or inquiry to us, a fast, free online laser cutting quote of required aluminum components will be back. Get your Aluminum Laser Cut Parts into fabrication in the shortest time.

-

Precision Laser Cutting 6061 T6 Aluminum Sheet

-

Fiber Laser Cut Grooved Aluminum Panels

-

Precision Laser Cutting Aluminum 6061 Thin Pipe

-

Aluminum 7075 Laser Cutting Digital Accessories

-

Pipe Laser Cutting Aluminum Speaker Enclosure

-

Fiber Laser Cutting 6063 Aluminum Sheet

-

Precision Laser Cutting Brushed Aluminum 6061 Plate

The Advantage Of Aluminum Laser Cutting

- Thin Cutting Seam: The cutting seam of laser cutting is generally 0.1mm-0.2mm

- The cutting surface is smooth: the cutting surface of laser cutting has no burrs and no slag.

- Small thermal deformation: The laser processing of laser processing has thin slits, high speed and concentrated energy, so the heat transmitted to the material to be cut is small, and the deformation of the material is also very small.

- It is suitable for the processing of large-size products: the mold manufacturing cost of large-size products is very high, and laser processing does not require any mold manufacturing. For this, we recommend changing the needle to one size larger, and try to adjust the feeding time of the feeding dog. Slow down, and you can fix this problem. Moreover, laser processing completely avoids the slump formed when the material is punched and sheared, which can greatly reduce the production cost of the enterprise and improve the grade of the product.

- It is very suitable for the development of new products and shortens the research and development cycle: once the product drawings are formed, laser processing can be carried out immediately, and you can get the physical objects of the new products in the shortest time.

- Material saving: laser processing adopts computer programming, laser equipment can cut different shapes of products, and different combinations of upper and lower thread thicknesses of the interlock sewing machine will definitely produce different sewing effects. Under normal circumstances, the upper and lower lines should be the same thickness.

The Process Parameters Of Aluminum Laser Cutting

| Duty Cycle | % | 20 | 25 | 25 | 25 | 25 | 25 | 25 |

| Delay Time | Scc | 0.2 | 0.2 | 0.5 | l | l | 2 | |

| Focus Position | mm | -0.5 | -1 | -2 | o | 0 | o | o |

| Auxiliary Gas CO2 Pressure | bar | 1 | 1 | |||||

| Small Circle | ||||||||

| Low Light Mode | sp | sp | ||||||

| Laser Frequency | Hz | 200 | 750 | 750 | ||||

| Laser Power | w | 80O | 1200 | 120O | 150O | 180O | 2200 | |

| Duty Cycle | % | 25 | 50 | 55 | ||||

| Feed Rate | mm/min | 500 | 130O | 100O | ooo | 80O | 50o | |

| People Circle | ||||||||

| Laser Mode | cw | cw | cw | cw | cw | cw | cw | |

| Laser Power | w | 1200 | 150O | 150O | 2200 | 220O | 2200 | 2200 |

| Feed Rate | mm/min | 300o | 250O | 180O | 160O | 1300 | 100O | 500 |

| Cutting | ||||||||

| Laser Mode | cw | cw | cw | cw | cw | cw | cw | |

| Laser Power | w | 800 | 1100 | 180O | 1800O | 1800 | 1500 | 1500 |

| Feed Rate | mm/min | 1500 | 2000 | 2500 | 1350 | 1100 | 500-800 | 275 |

| Laser Mode | cw | cw | cw | cw | cw | cw | cw | |

| Laser Power | w | 1500 | 1800 | 2200 | 2200 | 2200 | 2200 | 1800 |

| Feed Rate | mm/min | 4000 | 3500 | 2700 | 1600 | 1300 | 1000 | 350 |

| Laser Mode | cw | cw | cw | |||||

| Laser Power | 180O | 2200 | ||||||

| Feed Rate | mmmin | 500 | ||||||

| Laser Mode | ||||||||

| Laser Power | 220o | |||||||

| Feed Rate | mm/min | 6000 |

The Precautions Of Aluminum Laser Cutting

- It is not recommended for customers to cut aluminum sheet materials for a long time.

- When cutting materials with a thickness of ≥4mm, the parameters for cutting small holes should be used when cutting p1.5mm holes, the oxygen pressure should be 4Bar (60Psi), or the speed at the beginning of cutting should be 20-30% of the normal cutting speed.

- The cut hole refers to the hole with the hole diameter ≤ 5mm and the plate thickness ≤ 3mm, or the plate thickness > 3mm and the hole diameter not larger than the plate thickness size.

- Cutting large holes refers to holes with a diameter of ≥5mm and a plate thickness of <3mm, or a plate thickness of >3mm and a hole diameter greater than the plate thickness.