Aluminum Alloy In Metal CNC Spinning

Aluminum is one of the most popular materials in the metal spinning process because of its great properties such as lightweight and corrosion resistance, as well as cost-effectiveness and diversity in grades. Aluminum spinning is a process of shaping a piece of aluminum sheet material to create the desired part or product, it involves material rotate or deformation. Common aluminum spinning processes include spinning, welding, forming,drilling,molds manufacturing, joining, etc. The selection of the process is depending on the particular requirements of the application. Based on the characteristics of aluminum sheet metal parts, they are used throughout a wide range of industrial sectors from led to automotive to food industries. Forming and spinning are usually necessary steps in the fabrication of metal spinning aluminium.

The Aluminium And Aluminum Alloy Grades Of Precision CNC Spinning

Aluminum is a malleable metal known for its significantly low density and high corrosion resistance, making it ideal for a range of applications within the construction, transportation, and aerospace industries.Aluminum spinning sheet is available in different grades depending on the application of the finished product. Common examples of aluminum spinning grades include:

- Aluminum 1100 is the commercially pure grade of aluminum alloys, with an aluminum composition of 99%. It is characterized as soft and lower strength.

- Aluminum 3003 is a non-heat treatable alloy consisting of copper, iron, manganese, and trace amounts of other elements. It is regarded for its good corrosion resistance and moderate strength.

- Aluminum 5052 primarily consists of magnesium and chromium, and is often referred to as “anodize-quality aluminum” due to its excellent finishing and anodized coating properties. It has good strength and flexibility.

- Aluminum 6061 has two main alloys: magnesium and silicon. It is known to have relatively high strength, high corrosion resistance, and good overall workability.

- Aluminum 2024 uses copper as its primary alloy. It is known for having a good strength-to-weight-ratio and good fatigue resistance – but has poor resistance to corrosion.

- Aluminum 7075 primarily consists of a zinc alloy and is considered one of the highest strength aluminum alloys available, making it ideal for parts that undergo heavy stress. Its strength is comparable to that of many steel materials.

Aluminum Spinning Service – Aluminum CNC Spinning Parts Suppliers & Company

If your project requires aluminium cnc spinning parts, Be-cu.com should be a top choice on your list. As an experienced metal machining and fabrication company, we are professionals at manufacturing various custom aluminum products including metal spinning parts and components for particular applications. Whether you need fittings or parts for High Power LED Light,vehicle doors, medical equipment, digital devices, and customer products, our aluminium cnc spinning services can offer you high-precision aluminum spinning parts with significant benefits. We have been a quick-turn and reliable online manufacturer and supplier for more than 30 years and we are an ISO 9001:2015 certified metal spinning manufacturer, always bringing demanding and OEM products with high accuracy and precision. Other than aluminum spinning manufacturing, we can also handle other material and processes for metals in our factory.

The Advantage Of Aluminum Spinning

Metal spinning offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, aluminum spinning tools are typically 10% of the cost.

- Shorter Lead Times – The aluminum spinning process amounts to significantly shorter turnaround times – tools and spun components can be available within weeks rather than months.

- Maximum Design Flexibility – aluminum spinning tools can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – aluminum spinning produces smooth, durable objects without seams or welds, for parts require feature superior strength and great aesthetics.

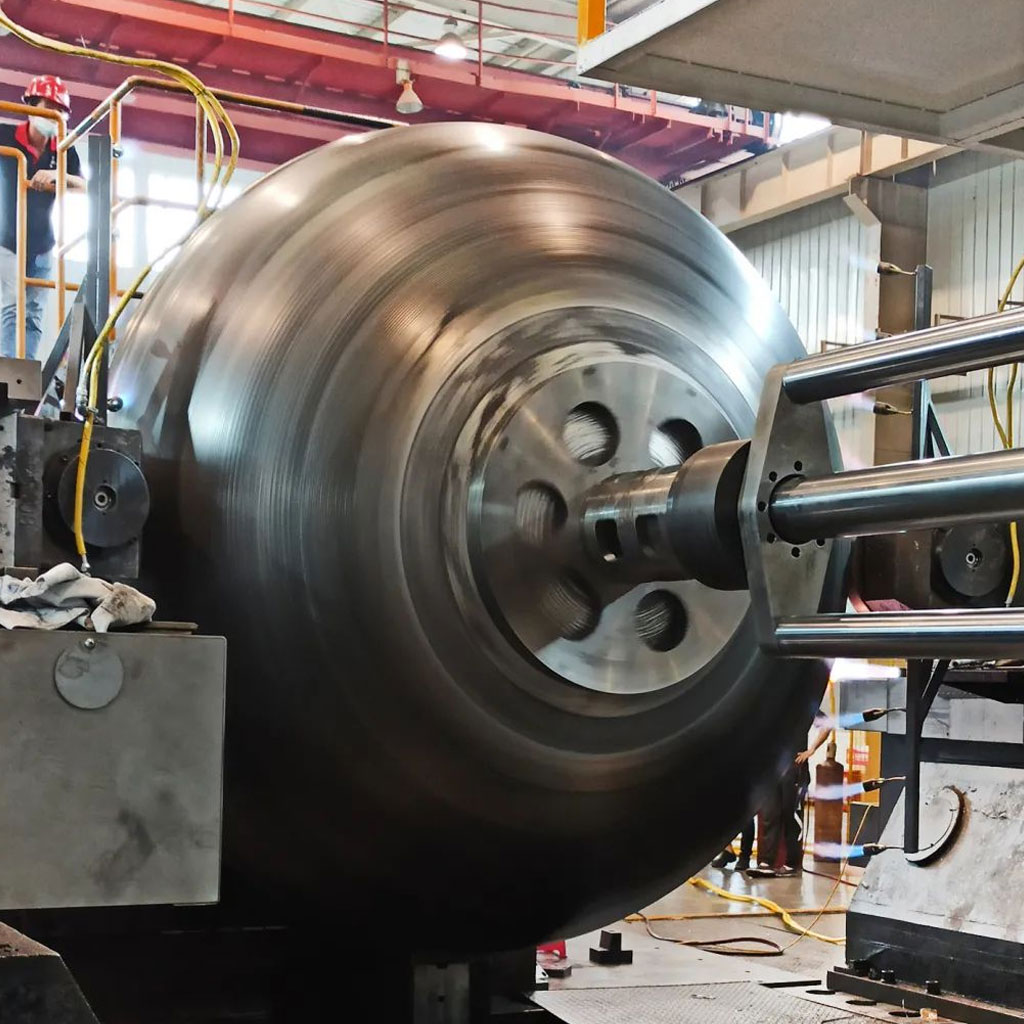

Our Case Studies Gallery Of Spun Aluminum CNC Spinning

Put Be-cu.com’ experience to work for all of your aluminum spinning and spin forming needs—from traditional manual aluminum spinning to cutting edge CNC aluminum spinning. The spun aluminum spinning process is perfect for a wide variety of industries that require consistent tolerances, fast turn-around, and uncompromising quality.