Motor Front And Rear Covers

- Product Name: Aluminum Parts

- No+Color:Custom

- Surface Treatment:Oxidation

- Product Material: Aluminum Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Cnc Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Motor CNC Parts

- Production Process: Cnc Machining

- Size: According To Customer’s Drawings

High-Quality Metal CNC Machining Motor Front And Rear Covers

Motor front and rear covers refer to the protective enclosures or casings that are typically used in various types of electric motors, such as those found in appliances, machinery, vehicles, and industrial equipment. In many applications, electric motors are exposed to moving parts or areas where people may come into contact with them.

Front and rear covers provide a barrier that prevents accidental contact with the motor’s moving parts, reducing the risk of injury.The front and rear covers shield the internal components of the motor, including the rotor, stator, windings, and bearings, from environmental factors such as dust, moisture, and contaminants. This protection helps extend the motor’s lifespan and ensures its reliable operation.Some motor covers are designed with built-in vents or openings to facilitate cooling and ventilation. These openings allow air to flow through the motor, dissipating heat generated during operation. Proper cooling is essential for preventing overheating and ensuring the motor operates efficiently.Electric motors can produce noise during operation.

The covers can help dampen this noise to some extent, making the motor quieter and reducing noise pollution in the surrounding environment. Motor covers can also have aesthetic and structural purposes. They can enhance the appearance of the motor, making it look more polished and professional. Additionally, the covers can add structural integrity to the motor assembly, helping to maintain its shape and protect it from physical damage.

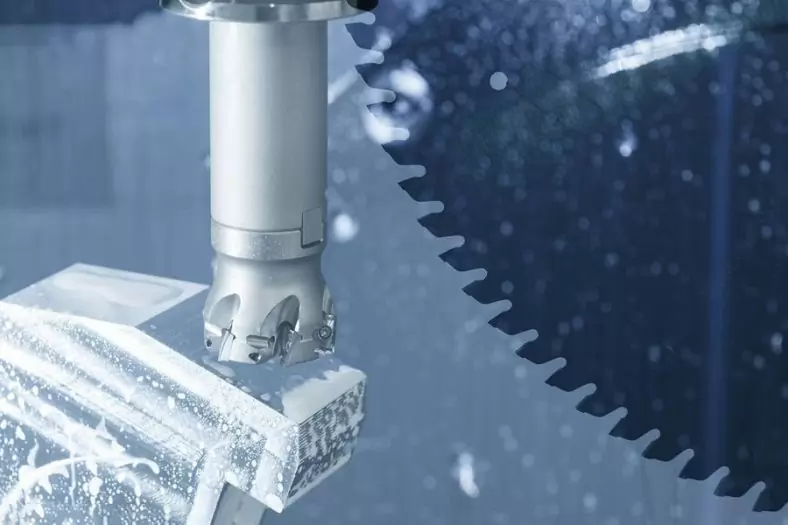

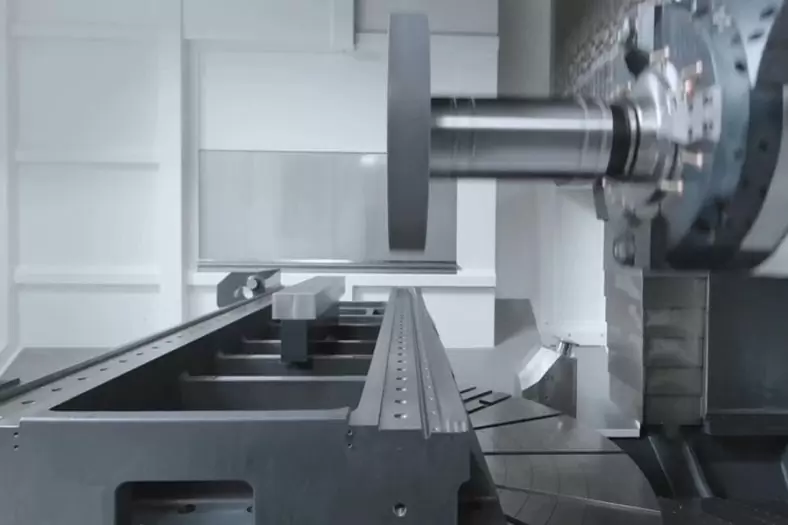

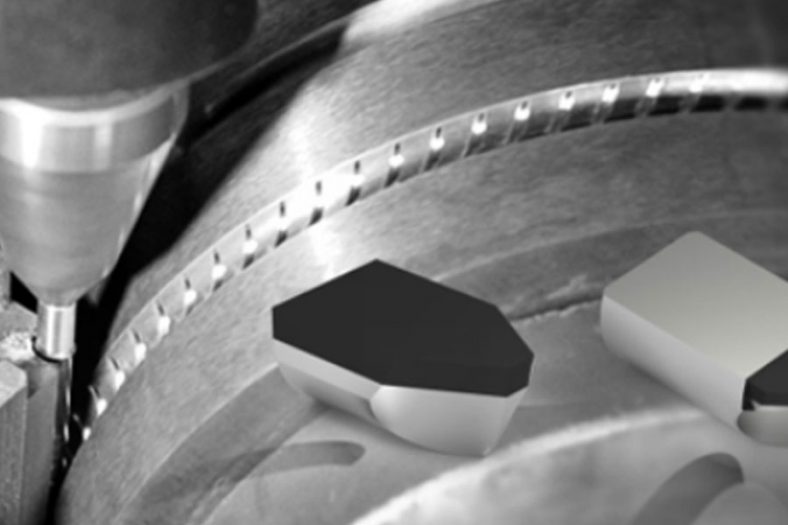

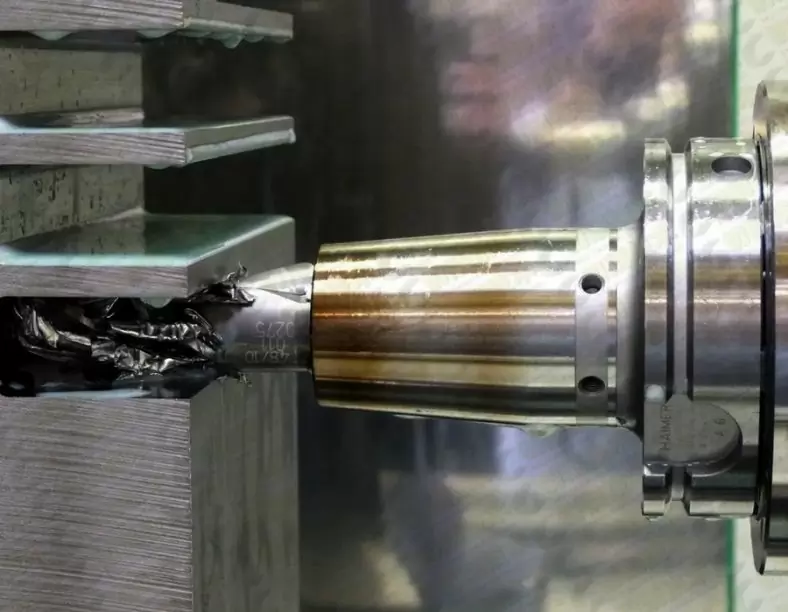

CNC machining is perfect for manufacturing Motor Front And Rear Covers.Be-Cu prototype offers Metal Motor parts CNC Machining service, including Front And Rear Covers production.Our CNC routers are able to achieve sharp edges and tight tolerances on materials that would be otherwise affected by the heat of a laser. Our online 3 axis and 4 axis CNC machining service will ensure your parts are cut to spec every time.Our CNC routers can produce one part, or thousands of parts at high-speeds that lead to faster production times and lower prices.

The Advantages Of Metal CNC Machining Motor Front And Rear Covers

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Metal CNC Machining Motor Front And Rear Covers

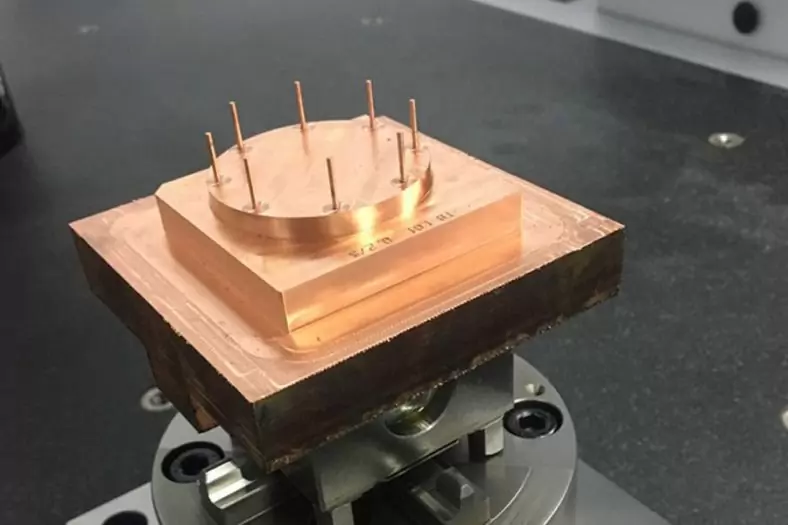

| Material | Aluminum 2024 |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Automotive,Motorcycle,Motors |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Milling Company

Looking for low cost CNC milling parts with unparalleled quality? BE-CU Prototype is a professional China CNC company provides superior precision CNC milling service with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning. Our high-quality rapid CNC milling products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc.