Stainless Steel Chemical Etching

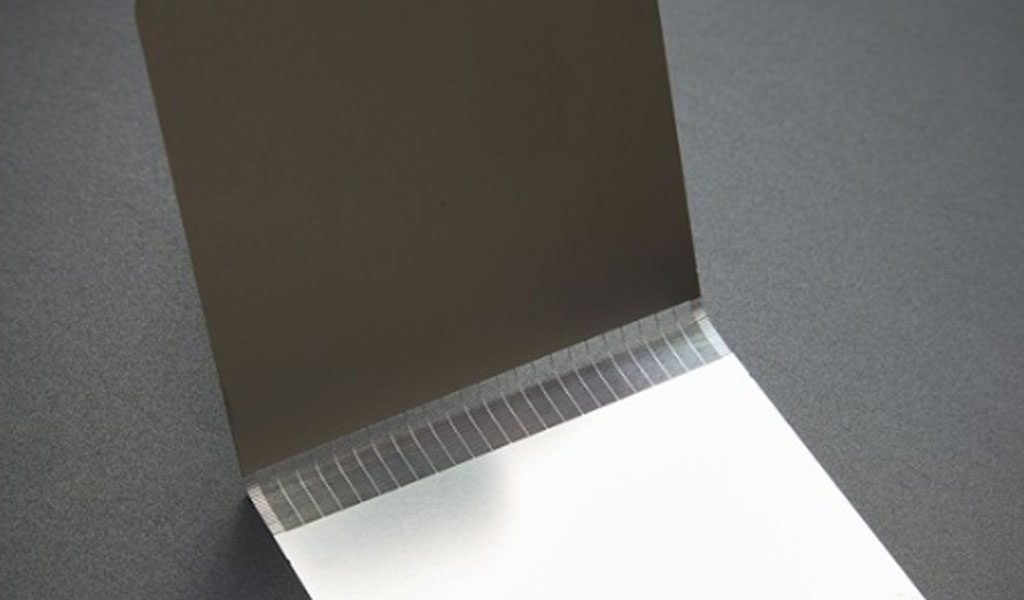

Stainless Steel Etching is a chemical method on the surface of stainless steel, using the strong oxidation of ferric chloride to corrode various patterns on the surface of stainless steel. With mirror panel, wire drawing board and sandblasting board as the bottom plate, after corrosion treatment, deep processing is carried out on the surface of the object. The stainless steel etching plate can be processed with various complex processes such as partial patterns, wire drawing, gold inlay, and partial titanium gold. The stainless steel etched plate realizes the effect of light and dark patterns and brilliant colors.

What Is Stainless Steel Etching

Etched stainless steel is a product that uses acid-resistant ink to print a certain pattern on the surface of stainless steel, and then immerses it in acid solution to etch it. The depth of etched patterns can be selectively controlled, and can be matched with painting and oxidation coloring methods to produce handicrafts with a high artistic level.Stainless steel etched plates are etched with various patterns on the surface of stainless steel by chemical methods.With 8K mirror panel, wire drawing board, and sandblasting board as the base plate, after etching treatment, the surface of the object is further processed.

The stainless steel etching plate can be processed with various complex processes such as partial texture, wire drawing, gold inlay, and partial titanium gold. , Stainless steel etched plate to achieve the effect of light and dark patterns and brilliant colors.

How To Etch Stainless Steel Etching Mesh?

The thickness of the stainless steel mesh etching material is 0.1mm-2.0mm, the etching accuracy can reach 0., and the tolerance is the smallest ±0. Stainless steel etching is to use the method of chemical etching to corrode stainless steel. Through film exposure plate making, after the stainless steel is developed, the protective film of the part that needs to be etched is removed, and the chemical solution is contacted to dissolve the left and right sides of the stainless steel that need to be etched, forming hollows and bumps.

Stainless Steel Etching Service – Stainless Steel Chemical Etching Company

We offer a complete stainless steel precision etching service and can produce complex stainless steel parts with 11 different types of stainless steel(include Austenitic (300 series), ferritic/martensitic (400 series), precipitation hardened (17-4, 17-7), duplex, super duplex etc.,). Stainless steel parts are great for applications that require high strength, corrosion resistance, heat tolerance, impact resistance, and overall versatility. We operate almost every etch machine and can etching whatever you need, from simple, ‘as-etched’ work holdings to complex, organic geometries with tight tolerances.

And we are always committed to producing high-quality etched parts in line with your budget and lead time demand. Think about Be-cu.com if other precision etching shops have no capability to complete your high-standard components.

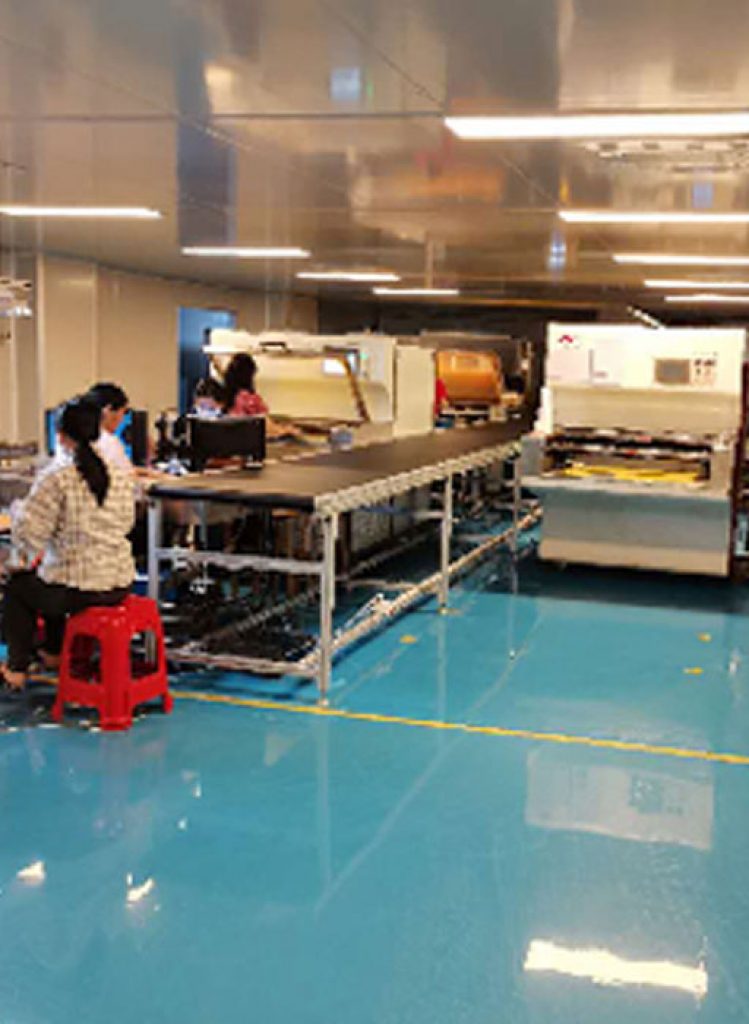

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

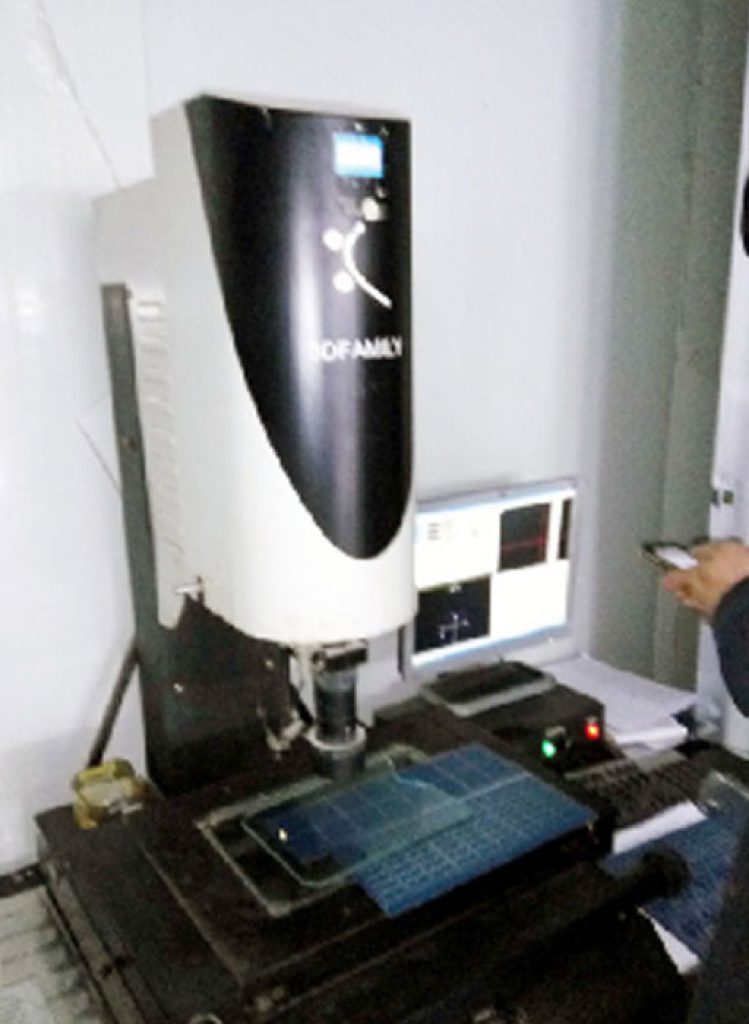

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

Stainless Steel Chemical Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

Inspection For Etching

Exposure

Stainless Steel Chemical Etching Parts & Case Studies In China

As one of professional Stainless Steel Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Stainless Steel material characteristics. So we can offer you the best etching Copper solution according to your requirements of Stainless Steel parts and products.

-

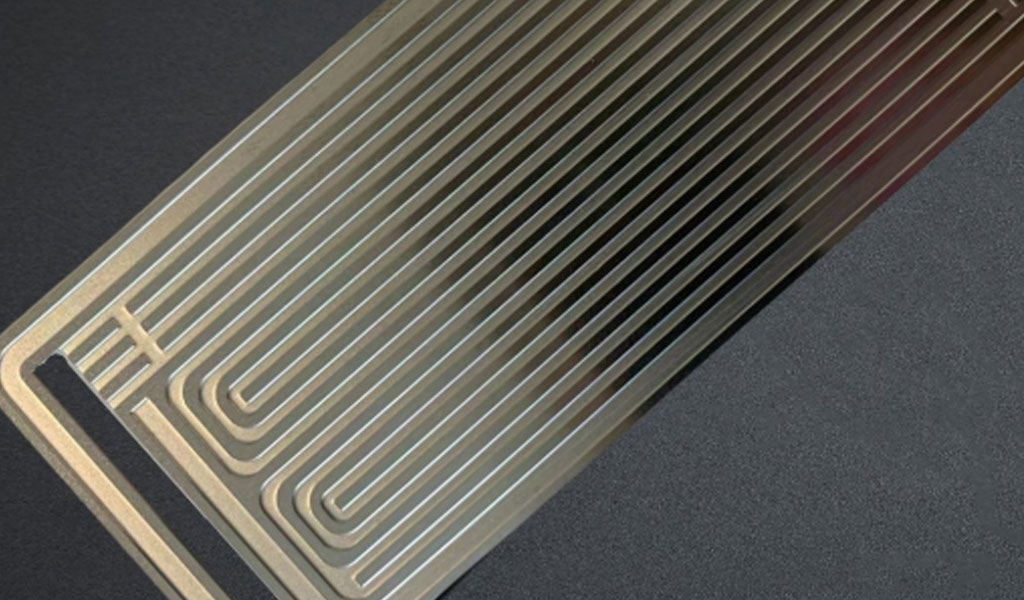

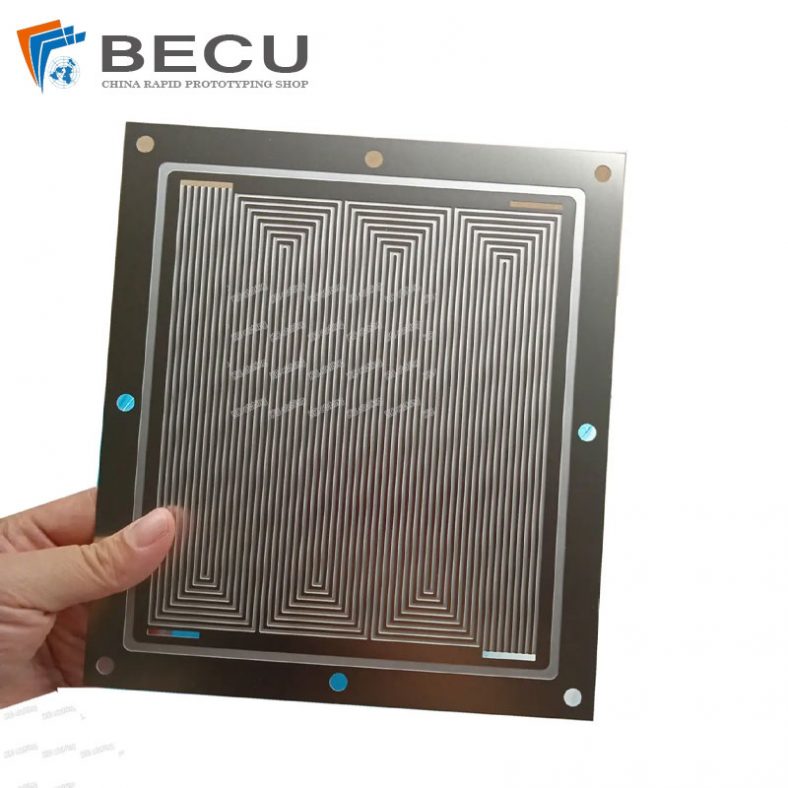

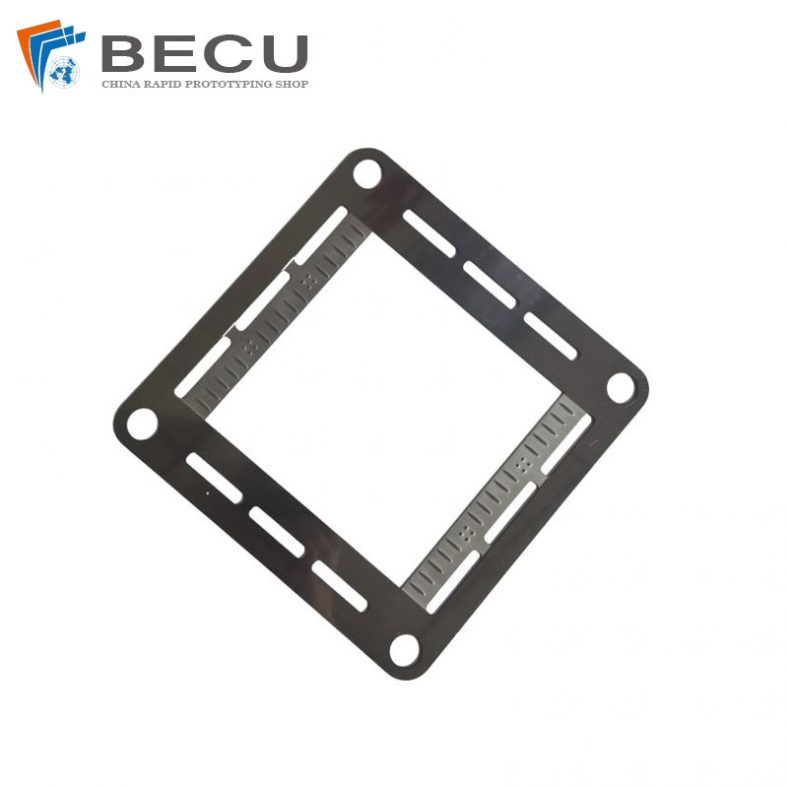

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

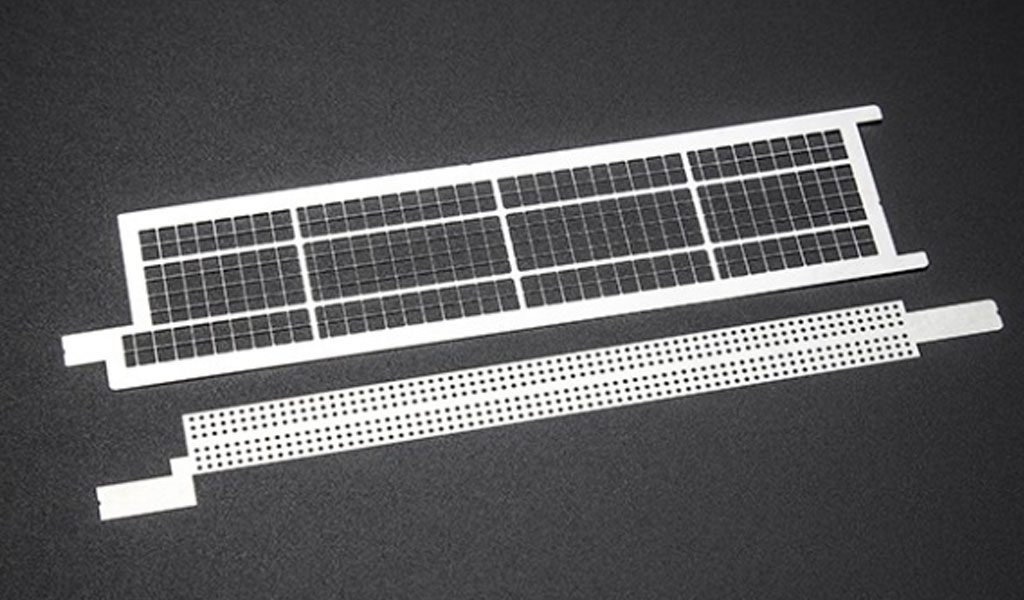

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks

-

Chemical Etching Stainless Steel 316 Bipolar Flow Plates

-

Laser Cut And Etching 303 Jewelry Pendant

-

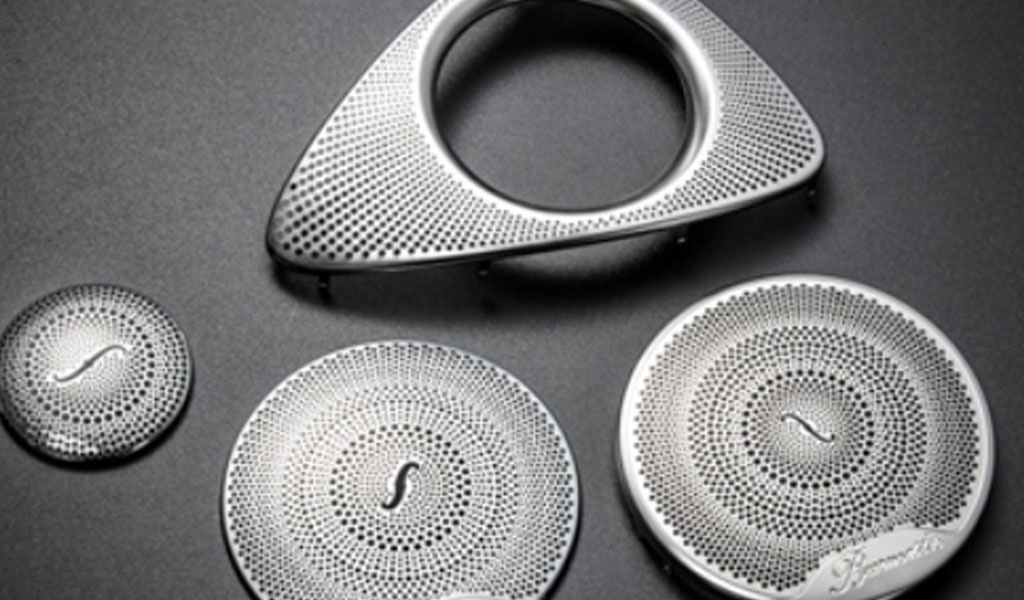

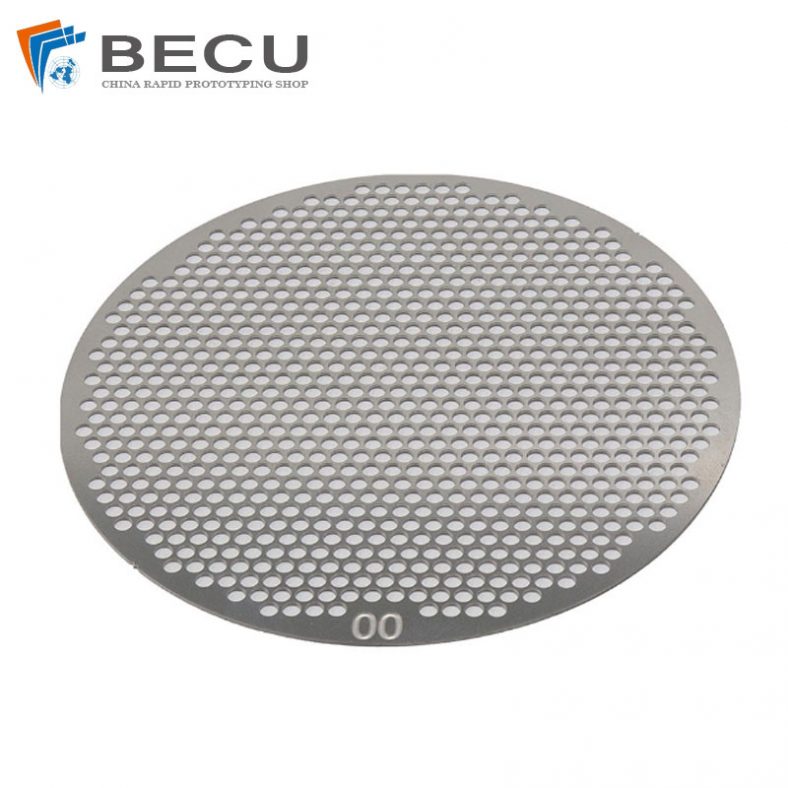

Photo Chemical Etching Microporous Dust Filter For Automotive Speaker

-

Precision Etching Automotive Audio Grille

-

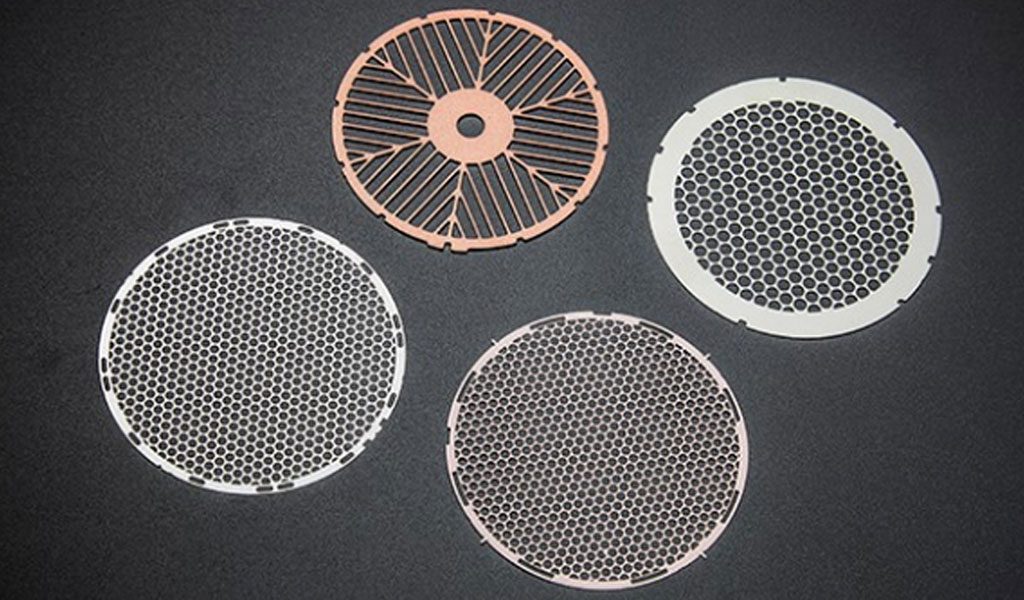

Metal Etching 5 Inch Round Car Horn Protection Net

Surface Finishing Options for Stainless Steel Chemical Etching

Parts made using photo etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

The Process Options for Stainless Steel Chemical Etching

The traditional process requires multiple steps:

Stainless steel plate—greasing—washing—drying—screen printing—drying—water immersion—etching pattern leaf (piece) washing—ink removal—washing—polishing—washing—coloring—washing leaf (piece) hardening treatment—sealing treatment— Drying of clear leaves (pieces)—inspection—product

So many processes are not only time-consuming and labor-intensive, but also generate a large amount of waste water and liquid discharge, causing serious pollution to the ecological environment. However, Digital Prinect has improved the traditional etching process and launched an etching superior version process. Before etching, only one step is required to complete the cumbersome process of the traditional process.

- Finalize the graphics and texts required by the customer in the computer

- Use the prepared graphics and texts to print the etching mask layer directly on the workpiece as needed through the etching software and inkjet printing equipment.

- Enter the metal etching process.

The stainless steel etching process adopts the etching optimized version process, and the required time is basically within 30 minutes according to the size of the workpiece, and the workpiece can be etched in the next step. Prinect’s etching and fine-tuning process has a unique effect on the fine processing of various stainless steel flat parts.

Online Cooperate With Stainless Steel Etching Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision etching and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.