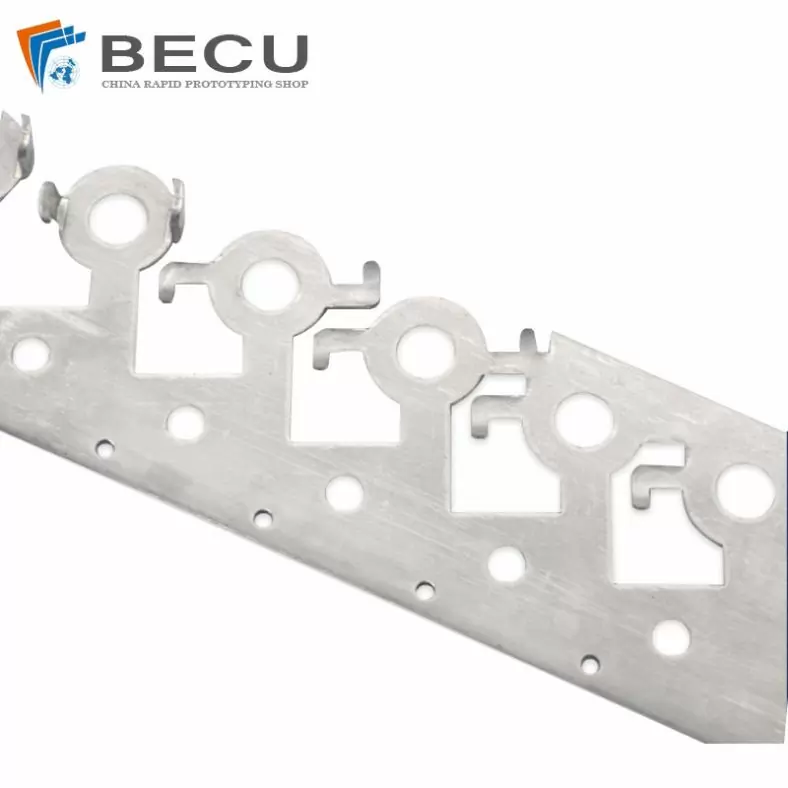

Precision Stamping For Stainless Steel

Stainless steel is one of the most sought after materials for both customers and manufacturers to utilize in their everyday operations. Stamping stainless steel is popular as steel comes in multiple grades and provides a number of benefits and features, making it suitable for various applications. To be classified as stainless steel, it must contain a minimum of 10% chromium, an element that grants stainless steel with its many unique properties such as resistance to corrosion and the ability to heal itself in the presence of oxygen.

Be-cu.com is a premier provider of Metal stamping services. Armed with extensive manufacturing experience and top-of-the-line precision stamping equipment, we can punching a broad selection of materials to customer specifications, including stainless steel.

Our products are widely used in automation, optics, communication electronics, medical, new energy and other fields. The purpose of our company is excellent quality, reasonable price, and good service. We provide professional technical data support and reliable solutions to meet the customization needs of various quality stamping products.

For every stamping order, we provide SGS, RoHS material certifications, and full dimensional inspection reports upon your request to make sure stamping meet your application’s requirements.If you are looking for a precision stamping shop which can produce your stainless steel parts, please feel free to contact us. Because we are really good at stamping stainless steel.

The Stainless Steel Alloy Grades Of Precision Stamping

Three basic types of steel are used in the stamping industry: austenitic, ferritic, and martensitic, each of which varies slightly in composition and, consequently, characteristics. These differences make them suitable for different applications. At Be-cu.com(Pintejin Group), we provide the most popular stainless alloys on the market in order to meet your business needs. These alloys include:

- 301 austenitic stainless steel, with great strength and ductility, used in automotive parts.

- 304 austenitic stainless steel, the most widely use stainless steel, corrosion resistance, used in constructions, food processing, etc.

- 316 austenitic stainless steel, added with molybdenum, resistance to pitting, used in constructions parts, ships, hot water system, etc.

- 321 & 347 Stainless Steel:Variations of the basic 18-8 composition. Stabilized by alloy addition to improve weldability and high-temperature service.

- 410 martensitic stainless steel, corrosion resistance and heat resistance, used in nuts, bolts, cutlery, turbine parts, etc.

- 420 martensitic stainless steel, High carbon grade with good resistance to atmosphere under hardened conditions, used in cookware, medical devices, ect.

- 430 ferritic stainless steel, corrosion resistance, moldability, mechanical properties, used in automotive trim parts, component holders, fasteners

- Stamping 17-7PH Stainless Steel:Heat-treatable stainless steel with forming characteristics of 304. May be hardened up to 200 thousand tensile strength after cold forming.

In comparison to metals such as Inconel, brass, nickel, and titanium, stainless steel offers stronger resistances and longer life cycles at a better cost. In the ideal process for machining 304 and 316 stainless steels, there are several ways to make all 300 series stainless steels easier to stamping. Heat treatment can be performed to make the metal easier to punching, for example, normalizing heats the steel to a temperature higher than the annealing temperature. Keeping it long enough to produce smaller austenite grains improves the softness of the steel. These types of steel have low thermal conductivity. Be careful not to overheat the surface, which can also cause distortion that is difficult to repair. At Be-cu.com, we have 30 years of experience in the precision stamping of stainless steel. For more information on our precision stamping stainless steel offerings, please contact us or request a quote today.

Stainless Steel Stamping Services – Precision Stamping For Stainless Steel

We, at Be-cu.com, are committed to providing high-quality stainless steel stamping services at competitive prices. Our broad experience combined with our expertise has helped us take up various complex projects with ease. Our long list of happy and satisfied customers is the testament of our commitment to provide quality services at fastest turnaround times.Press rating ranges from 100 to 700 ton with maximum press bed length of 96 in. and maximum press bed width of 48 in. Stock thicknesses can be from 0.008 to 0.250 in.

Other capabilities include prototyping, wire EDM, sorting, assembly and spot, projection, robotic and MIG welding. In addition to our precision stamping capabilities, we provide a range of value-added services to ensure we can serve as a single source for all stainless steel stamping component needs. These services include powder coating, color coating, welding, grinding, tumbling, deburring, chamfering, stress relieving, forming, self-clinching hardware installation, shot peening and blasting, packaging, brazing, silk screening, electroplating, heat treating, and assembly. Contact us today for additional information on our stainless steel stamping services. Request a quote to partner with us on your next stainless steel stamping project.

The Advantage Of Stainless Steel Stamping

Metal Stamping offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, stainless steel stamping tools are typically 30% of the cost.

- Shorter Lead Times – The stainless steel Stamping process amounts to significantly shorter turnaround times – tools and stamping components can be available within weeks rather than months.

- Maximum Design Flexibility – Stainless Steel Stamping mold can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – stainless steel stamping produces smooth, durable objects without seams or sheet metal, for parts require feature superior strength and great aesthetics.

Manufacturing Of Custom Stainless Steel Stamping Parts

If you need assistance on your custom Stainless Steel Stamping projects, we will be one of the most capable and affordable production sources with our technology, experience, and skills. Our strict implementation of ISO9001 quality system standards, and the combination of efficient production processes and flexible custom engineering enable us to deliver complex projects in short turnaround times and provide excellent product quality.

Our Parts Case Studies Gallery Of Stainless Steel Stamping

We perform an efficient, accurate, and cost-effective process in-house to provide superior product results for your stainless steel stamping.Whether you require punching stainless steel pieces or custom stainless steel parts for your automotive, aerospace applications or medical device component, we can easily help you. With our expertise in precision stainless steel stamping and the ability to integrate external combined processes, we can ensure the best performance for your stamping stainless steel projects.