What is Stainless Steel Alloy & What is it Used for

Usually, people call alloy steel with chromium content greater than 12% or nickel content greater than 8% stainless steel. This steel has certain corrosion resistance in the atmosphere or in corrosive media, and has higher strength at higher temperatures (>450°C). Steel with a chromium content of 16% to 18% is called acid-resistant steel or acid-resistant stainless steel, which is commonly referred to as stainless steel.

When the chromium content in steel reaches more than 12%, in contact with oxidizing medium, due to electrochemical action, a chromium-rich passivation film is quickly formed on the surface to protect the inside of the metal from corrosion; but in non-oxidative corrosion In the medium, it is still not easy to form a solid passivation film. In order to improve the corrosion resistance of steel, usually increase the proportion of chromium or add alloying elements that can promote passivation, such as Ni, Mo, Mn, Cu, Nb, Ti, W, Co, etc. These elements not only improve the corrosion resistance of steel Corrosion ability, while changing the internal structure and physical and mechanical properties of steel.

The content of these alloying elements in steel is different, which has different effects on the properties of stainless steel. Some are magnetic, some are non-magnetic, some can be heat treated, and some cannot. Due to the above characteristics of stainless steel, it is more and more widely used in industrial sectors such as aviation, aerospace, chemical industry, petroleum, construction and food and in daily life. The contained alloy elements have a great influence on the machinability, and some are even difficult to cnc machining and cutting.

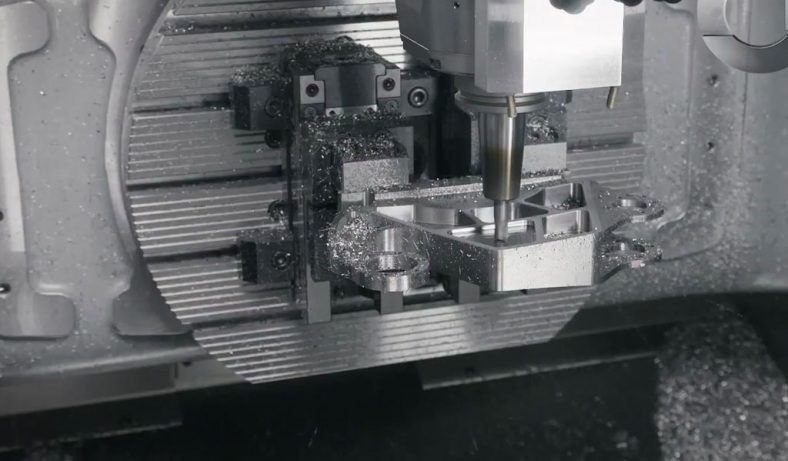

Cnc Machining Stainless Steel Services – Custom Stainless Steel Machining Parts China

Looking for reliable, quick-turn stainless steel machining services suppliers and CNC Machined product manufacturers?

BE-CU Prototype are always the leader in the stainless steel manufacturing industry and have been providing our customers with a full range of stainless steel cnc machining services,the service including stainless steel cnc milling,5 axis precision machining stainless steel parts,stainless steel cnc turning,stainless steel laser cutting,cnc drilling, punching and more. Also with stainless steel surface treatment such as stainless steel anodizing, brushing and sandblasting.. We will highly cooperate with customers’ needs, reply in time, cooperate with the modification of unreasonable drawings, and suggest the best production direction, also can help customers develop and produce new products.

Why Choose Our Stainless Cnc Machining Service?

- Save time and money for your stainless project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of stainless grades and alloy materials can be machined

- Custom complex stainless steel machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Material Type Of CNC Machining Stainless Steel Alloy

Stainless steel commonly used by BE-CU.COM is generally classified according to metallographic structure, and can be divided into the following five categories:

- Martensitic Stainless Steel: chromium content 12% to 18%, carbon content 0.1% to 0.5% (sometimes up to 1%), common ones are 1Cr13, 2Cr13, 3Cr13, 4Cr13, 1Cr17Ni2, 9Cr18, 9Cr18MoV, 30Cr13Mo, etc.

- Ferritic Stainless Steel: The chromium content is 12% to 30%, and the common ones are 0Cr13, 0Cr17Ti, 0Cr13Si4NbRE, 1Cr17, 1Cr17Ti, 1Cr17M02Ti, 1Cr25Ti, 1Cr28, etc.

- Austenitic Stainless Steel: 12%~25% complex, 7%~20% nickel (or more than 20%), the most typical representative is 1Cr18Ni9Ti, and the common ones are 00Cr18Ni10, 00Cr18Ni14Mo2Cu2, 0Cr18Ni12Mo2Ti, 0Cr18Ni18Mo2Cu2Ti, 0Cr23Ni28M03Cu3Ti, 1Cr14Mn14Ni, 2Cr13Mn9Ni4, 1Cr18Mn8Ni5N, etc.

- Austenitic + Ferritic Stainless Steel: Similar to austenitic stainless steel, it only contains a certain amount of ferrite in the structure. Common ones are 0Cr21Ni5Ti, 1Cr21Ni5Ti, 1Cr18Mn10Ni5M03N, 0Cr17Mn13Mo2N, 1Cr17Mn9Ni3M03Cu2N, Cr2bNi17M03CuSiN, 1Cr18Ni11Si4AlTi, etc.

- Precipitation Hardening Stainless Steel: contains high chromium, nickel and very low carbon, common ones are 0Cr17Ni4Cu4Nb, 0Cr17Ni7Al, 0Cr15Ni7M02Al, etc.

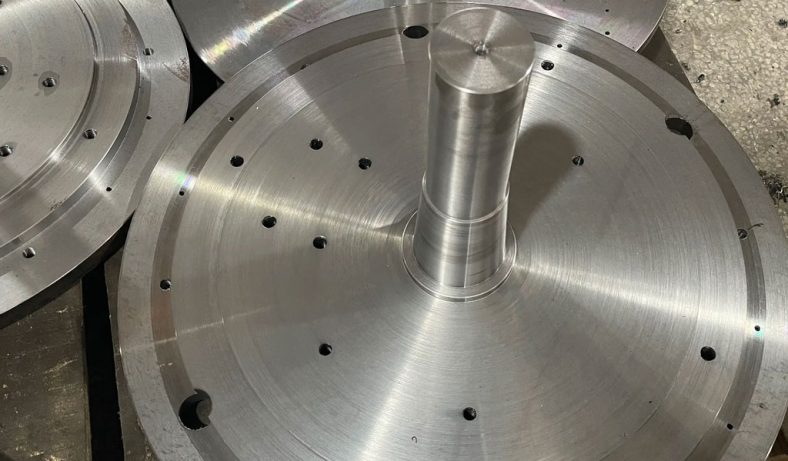

Top Stainless Steel Cnc Machining Parts & Case Studies

China Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make stainless steel prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making stainless steel concept models and precise functional components. Understanding the properties of different stainless steel alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on stainless steel alloy. Be-cu prototyping company provides a range of solutions for the machining of stainless steel parts.

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

Precision CNC Machining Inconel 718 Cast Impeller

-

CNC Machining Metal Chess Pieces,Board And Sets

-

CNC Machined Fidget Spinner

-

Custom Stainless Steel 316 Goblet By Turning

-

CNC Turning Stainless Steel 316 Grinding Core For Coffee Mill

-

Precision 316 Stainless Steel Cookware Boiler Cover For Kitchen

-

Precision Turning Stainless Steel 4 Minute Extra Thread Faucet

-

Swiss Turning Stainless Steel 17-4 PH Positioning Bushing

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod