Stainless Steel Sheet Metal Fabrication

Stainless steel is often the go to choice for Stainless Steel Sheet Metal Fabrication products due to its high corrosion resistance allowing it to be used in more rigorous environments where its lifespan would be considerably longer than other types of steel.Precision Sheet Metal Fabrication continues to manufacturing many different stainless steel into high quality products for many different industries. It offers substantial resistance to fire and heat meaning it can retain strength at high temperatures.

Be-cu.com has 300+ experience sheet metal manufacturing stainless steel parts for companies like Huawei, Airbus & Lixiang and more. Our team of highly skilled spinners offer 30+ years of combined expertise.

Benefits of Stainless Steel In Sheet Metal Fabrication

All stainless steels have a high resistance to corrosion and heat making it a durable metal with a long lifespan. Stainless steel is often able to withstand many years of use without showing signs of wear and tear. Other advantages include:

- High resistance to corrosion

- Easily cut, welded, formed, machined and fabricated readily

- Due to its strength, stainless steel can be used to reduce material thicknesses, reduce weight and costs

- 100% Recyclable

- Its unique hygienic properties makes it the first choice in hospitals, kitchens, food and pharmaceutical processing facilities

Stainless Steel Sheet Metal,An extremely popular material for sheet metal. It has a superior strength-to-weight ratio, is easy to fabricate and has a good price point. Also, as a strong, aesthetically pleasing, heat resistant and corrosion resistant steel, its applications are widespread. It is used for the fabrication of everything from cutlery to car parts.

The Stainless Steel Alloy Grades Of Metal Sheet Metal Fabrication

Each grade of stainless steel has a slightly different chemical composition and consequently a distinct physical appearance.

The 300 series of stainless steel is the most common with 304 stainless steel and 316 stainless steel being the most prevalent grades. Two other common grades are 409 stainless steel and 430 stainless steel.

| AISI Grade | Material Cost | Sheet Metal Fabrication Cost |

|---|---|---|

| 303 | Low | Low |

| 304 | Low | Medium-Low |

| 304L | Low | Medium-Low |

| 310 | Medium | Medium |

| 316 | Medium-Low | Medium |

| 316L | Medium-Low | Medium |

| 404 | Low | Medium-Low |

| 410 | Low | Low |

| 416 | Low | Low |

| 430 | Low | Low |

| 440C | Medium | Medium |

Stainless Steel Sheet Metal Fabrication Services – Sheet Metal Manufacturing Stainless Steel Parts Suppliers & Manufacturer

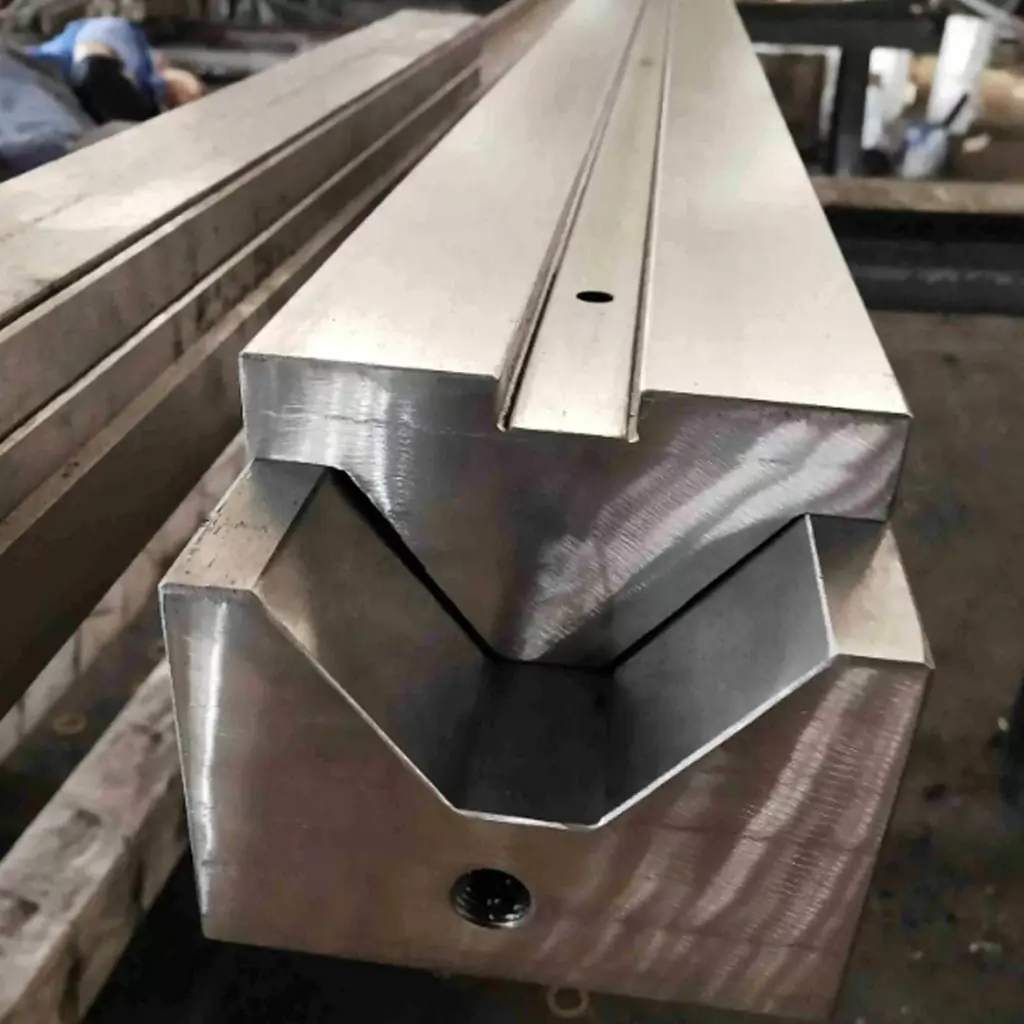

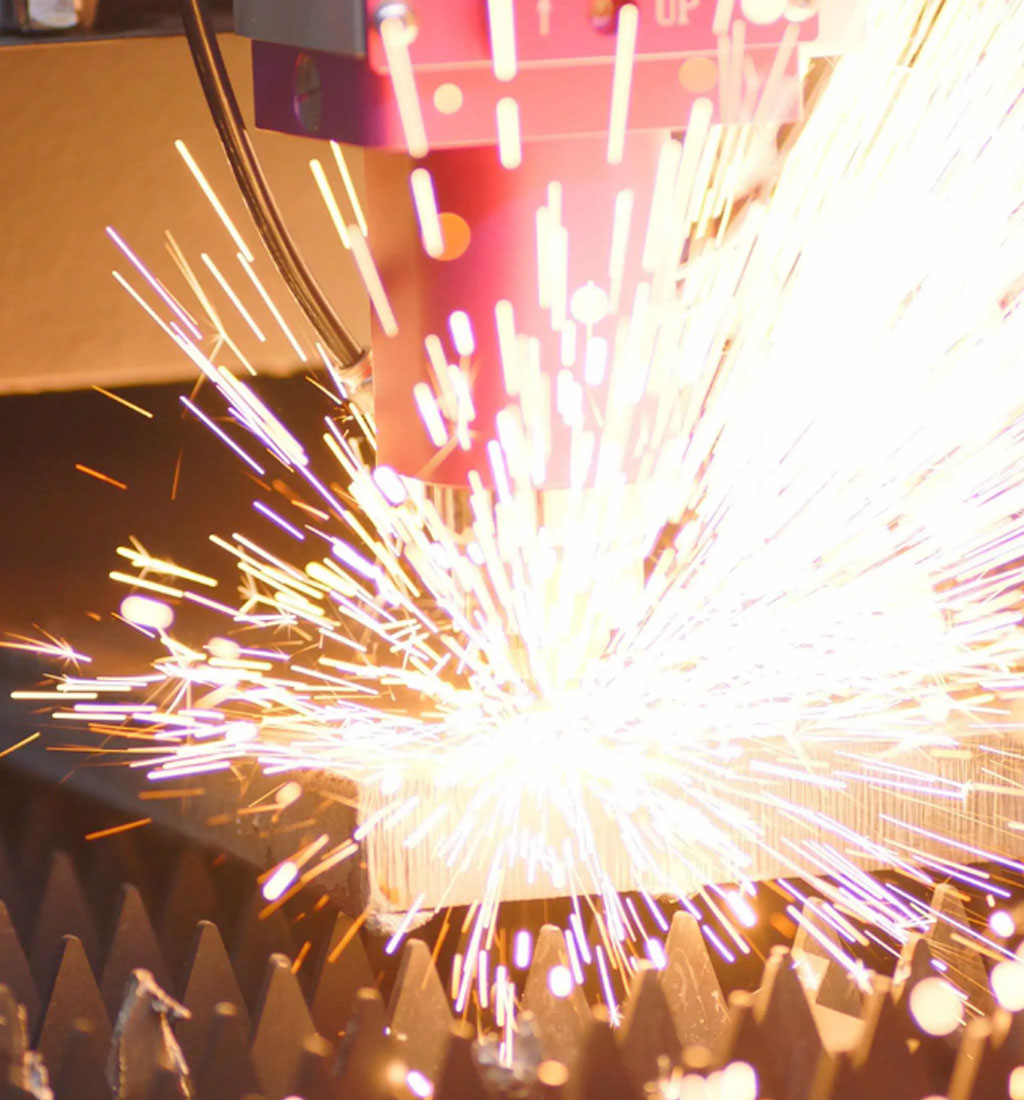

Our Engineering Department works closely with workshop to provide our customers with the highest quality, most stainless steel sheet metal manufacturing products. They use laser cutter, cnc bending machines, and specialized equipment. Various capabilities include contract manufacturing, edge rolling, forming, roll bending and welding. Finishing and secondary services such as hardware installation, tapping, deburring, cleaning, heat treating, plating, anodizing and painting available. The results are superior to shear forming. They have a number of benefits, including shorter lead times, lower costs, less waste, design flexibility, and so much more.

An array of materials can be used. Prototype and low to high volume production runs offered. They can work on diameters ranging from .250 to 72 inches, and thicknesses up to .250 inches. Tolerances of .001 inches can be reached. Spinning can be used for commercial/residential architectural, aluminum brake shape parts, wall panel systems, brackets, general flashings, rails, call button plates and ship building component parts and other products.Like all of our oem stainless steel parts services, we proudly stand behind the stainless steel sheet metal fabricationwe provide through Be-cu.com. Please contact us with any questions, and see below for details.

Why Use Our Stainless Steel Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal stainless steel parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication stainless steel to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off stainless steel laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom stainless steel laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Our Capabilities And Case Studies Gallery Of Stainless Steel Sheet Metal Fabrication

As a single-source manufacturing solutions provider, Be-cu.com offers a comprehensive group of services, including stainless steel sheet metal fabrication.

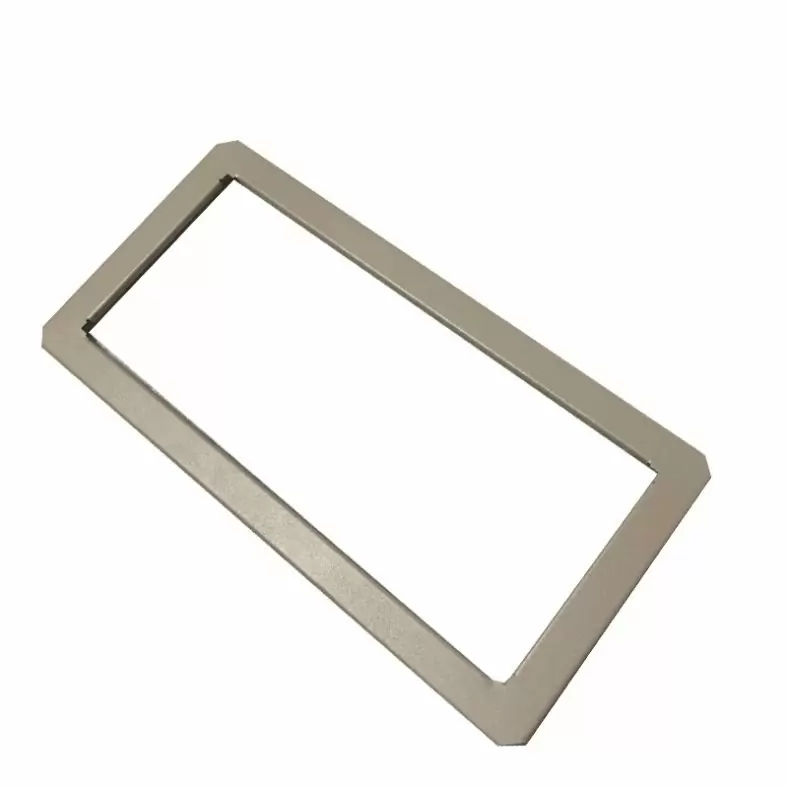

Using sheet metal fabrication, we manufacture stainless steel parts that exhibit a high degree of structural integrity.stainless steel sheet metal parts have no seams, enabling them to tolerate high pressure, and the sheet metal process itself realigns the grain structure of the metal to improve tensile strength. The enhanced metallurgical properties allow the use of lighter gauge metals to achieve the desired strength characteristics, which saves on material cost. sheet metal fabrication also results in high-quality finishes that reduce the need for secondary operations.

Inside our sheet metal fabrication department, we manufacture parts for a variety of purposes, from automotive applications to medical equipment. We have the capacity to achieve tolerances as close as ±0.005” for specialty applications that require extreme precision. Our sheet metal fabrication capabilities are supported by our machining, fabrication, and finishing departments, making the use of sheet metal fabrication virtually limitless. For more information about the sheet metal fabrication process or any of our other production capabilities, contact us directly.

-

Sheet Metal Fabrication Strongbox Enclosure

-

Sheet Metal Fabrication Large BBQ Grill Enclosure

-

Sheet Metal Fabrication For Large Japan Mill Machine Enclosure

-

Sheet Metal ATM Withdrawal Module Chassis Trunking Installation Parts

-

5G Outdoor Integrated Machine Connector Control Panel By Sheet Metal

-

Stainless Steel 304 IP65 IPC Enclosure By Sheet Metal

-

Sheet Metal Fabrication Custom Stainless Steel 316 Chassis Enclosure