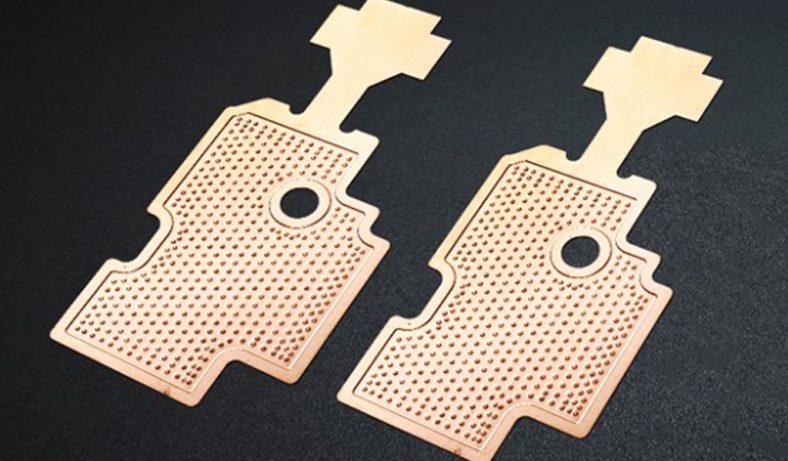

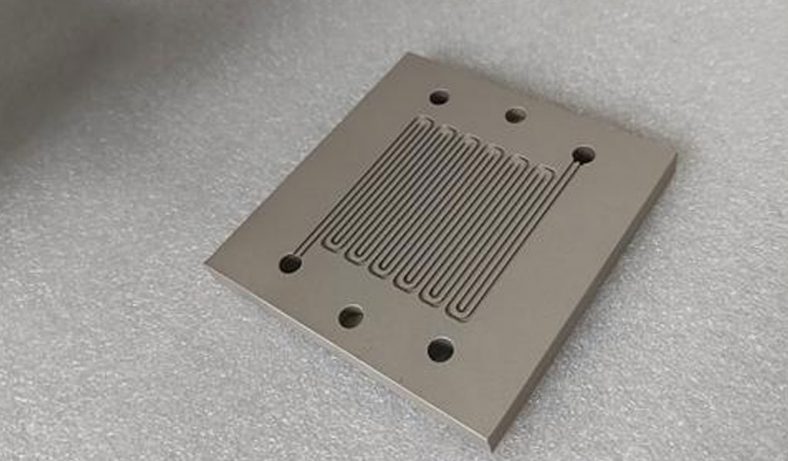

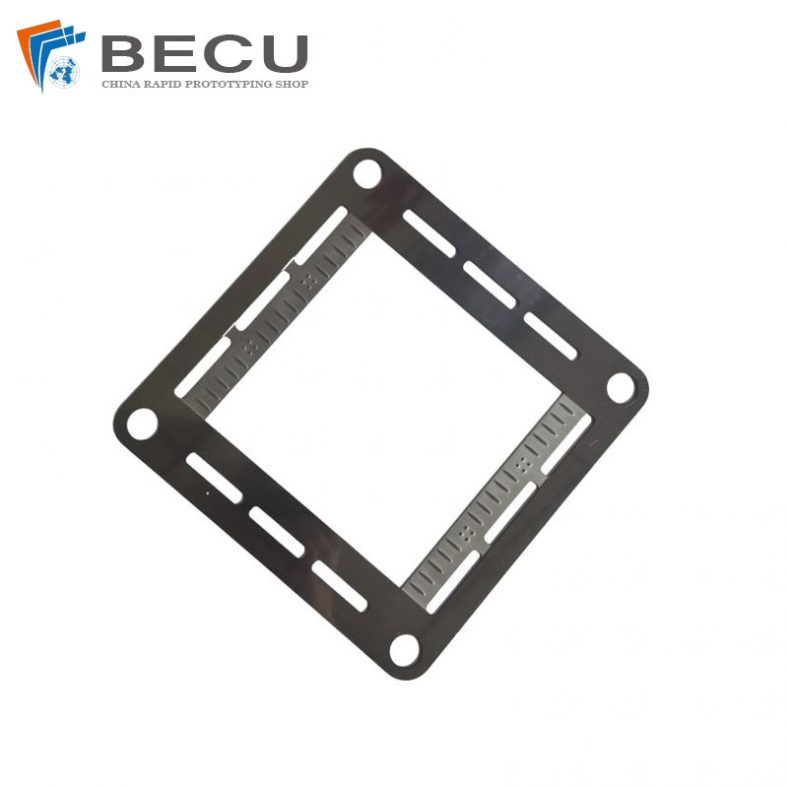

Bipolar Flow Plates

- Material: Stainless Steel 316

- Thickness: 0.01 mm

- Project Offer:Within 3 hours

- Process: Metal Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

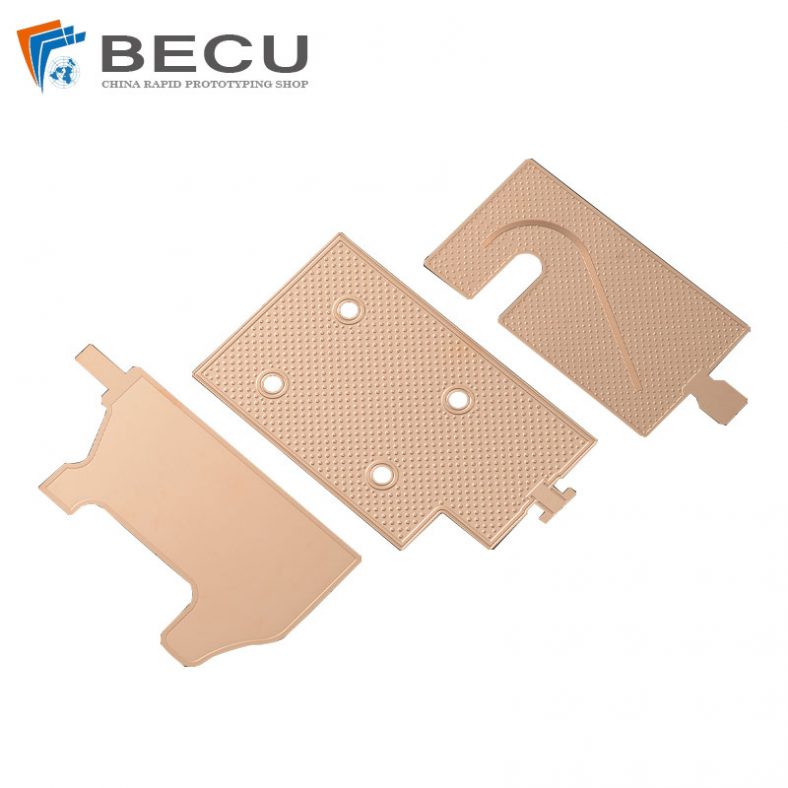

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Stainless Steel Etching

High-Quality Chemical Etching Stainless Steel 316 Bipolar Flow Plates

In the realm of advanced engineering, where precision meets innovation, stainless steel 316 emerges as a stalwart material, embodying durability, corrosion resistance, and mechanical strength. Within this landscape, the process of etching stainless steel 316 bipolar flow plates stands as a testament to the fusion of art and science. These intricate components play a pivotal role in various applications, from fuel cells to electrochemical processes, harnessing the power of controlled flow dynamics.

Etching, a centuries-old technique rooted in the realms of art and metallurgy, finds renewed relevance in modern engineering. It involves selectively removing material from a metal surface through chemical or electrolytic processes, unveiling intricate patterns or structures with meticulous precision. In the case of stainless steel 316 bipolar flow plates, etching assumes a pivotal role in shaping the flow channels and enhancing surface properties, thereby optimizing performance and efficiency.

The etching process for stainless steel 316 bipolar flow plates demands a harmonious blend of precision and innovation. Typically, it begins with surface preparation, where the stainless steel substrate undergoes rigorous cleaning and degreasing to ensure optimal adhesion of the etching resist. Subsequently, a patterned resist layer is applied to the surface, delineating the desired flow channels and features.

Next, the substrate is immersed in an etchant solution, meticulously tailored to selectively dissolve the exposed areas of the stainless steel. This chemical dance unfolds under controlled conditions, governed by parameters such as temperature, concentration, and duration, ensuring the attainment of precise geometries and surface characteristics.

Throughout the etching process, meticulous monitoring and quality control measures are imperative to uphold dimensional accuracy and reproducibility. Advanced technologies, including laser-assisted etching and photolithography, further refine the intricacy and resolution of the etched patterns, pushing the boundaries of what is achievable.

Why Choose Our Chemical Etching Stainless Steel 316 Bipolar Flow Plates Service?

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Chemical Etching Stainless Steel 316 Bipolar Flow Plates

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |

Metal Etching Material

The Detail Of BE-CU Metal Etching Company

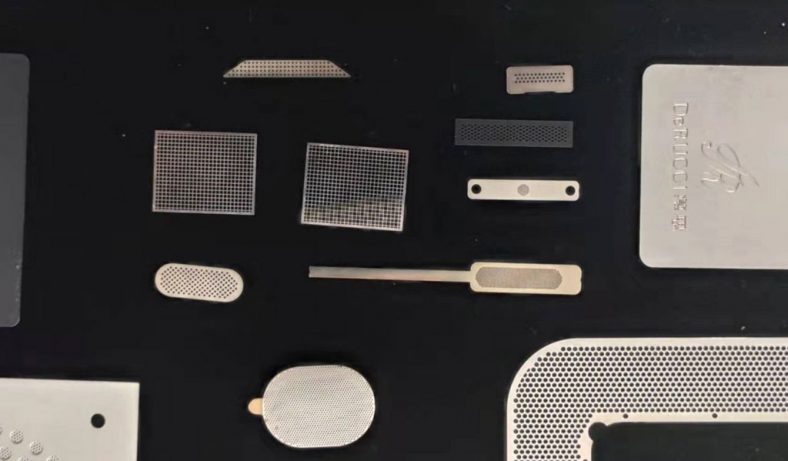

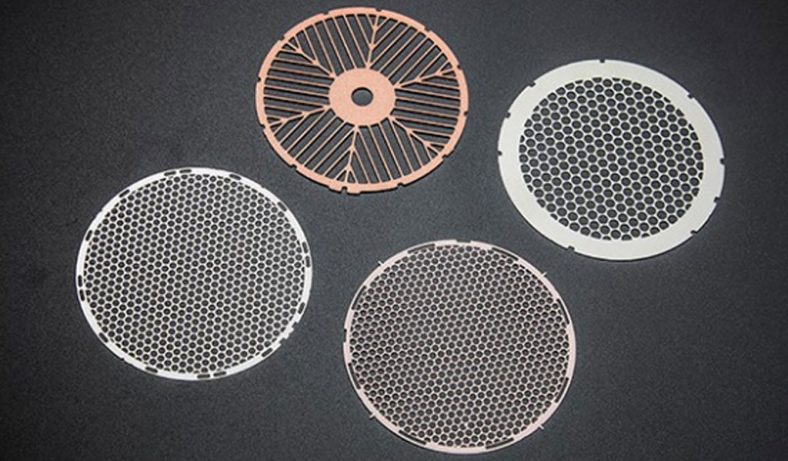

BE-CU Etch has specialized in high precision etchingindustry for over 10 years and supporting globalleading metal etching service in electronics, semiconductor-re-lated, car, new energy sources, and other industrieswith reliable technology and service. Our productsinclude lead frame,IGBT, metal bipolar plate for bat-tery, speaker mesh/interior parts for cars,5G heatsink(VC etching) and high precision metal accesso-ries for notebooks/computer/hardware, etc.

BE-CU precision etching company has passed the certifications of ISO9001/14001,IATF16949,QCO80000, IEC27001.We provide one-stop solutionwith chemical etching, stamping and surface finish, which make us could offer high quality productwith excellent competitive price to our customers and help customers reduce the cost and pressure of supply chain management.