Stainless Steel Alloy In Metal Spun

Stainless steel has excellent corrosion resistance, good formability, and great mechanical properties, which makes it an ideal material for metal spinning. Stainless steel metal sheet is a well-known building material that is durable and affordable.

There are so many ways stainless steel spinning parts are used, involves automotive, architecture, construction, medical, food, energy, heavy industry, chemical processing, etc. Unlike standard steel, stainless does not easy to rust, corrode or stain. Stainless steel spinning components are the go-to options when they need to be exposed to corrosive and extreme environments.

A selection of surface treatment methods can further improve its resistance.Once a stainless steel sheet has been transformed into a 3D part, it can be finished with different techniques. Not all stainless steel alloy for precision cnc spinning performs in the same way, you need to choose the right grade based on their cost and characteristics.

The Stainless Steel And Stainless Alloy Grades Of Precision CNC Spinning

One of the most commonly used materials in metal spinning operations is stainless steel, specifically the 300 and 400 series. Its strength and corrosion resistance make it an ideal material choice for a wide range of applications and industries. Additionally, both the 300 series and 400 series demonstrate unique characteristics that make them suitable for metal spinning projects.

300 SERIES SPINNING ALLOYS

Chromium-nickel austenitic stainless steel with good formability and good weldability

- 301 Stainless Steel – Alloy 301 is a commonly available austenitic stainless with good corrosion resistance and elevated carbon to allow for cold working to a variety of tempers.

- 302 Stainless Steel – Alloy 302 is a slightly higher carbon version of 304, often found in strip and wire forms. It is a tough, ductile grade that demonstrates comparable corrosion resistance, is non-magnetic, and is not hardenable by heat treatment.

- 303 Stainless Steel – Alloy 303 is the most readily machineable austenitic stainless steel; however, the sulfur addition does lower Alloy 303’s corrosion resistance to below that of Alloy 304.

- 304/304L/304H Stainless Steel – Alloy 304 is the most versatile and widely used alloy in the stainless steel family. The austenitic stainless steels are also considered to be the most weldable of the high-alloy steels and can be welded by all fusion and resistance welding processes.

- 316/316L Stainless Steel – Alloy 316 provides excellent elevated temperature tensile, creep and stress-rupture strengths, as well as outstanding formability and weldability.

- 317/317L/317LMN Stainless Steel – Alloy 317 is a higher chromium, nickel and molybdenum version of 316 stainless designed principally for increased strength and corrosion resistance.

- 321/321H Stainless Steel – Alloy 321 stainless is resistant to intergranular corrosion. It employs titanium as a stabilizing element against chromium carbide formation. This alloy also exhibits strength characteristics superior to those of 304 stainless.

- 347/347H Stainless Steel – Alloy 347 uses columbium as a stabilizing element to maximize its principal feature: resistance to intergranular corrosion. It can be used in applications requiring repeated heating in the range of 800 and 1650 F (427-899 C).

400 SERIES SPINNING ALLOYS

Ferritic and martensitic stainless steel, manganese-free, to some extent replace 304 stainless steel

- 405 Stainless Steel – Alloy 405 is a 12% chromium steel designed to be used in the as-welded condition. Unlike other 12% chromium steels, it is not subject to a great deal of hardening through air cooling form high temperatures.

- 409 Stainless Steel – Alloy 409 is an alloy designed principally for the automotive exhaust industry, although it has been used successfully in other industrial applications. It combines good elevated temperature corrosion resistance with medium strength, good formability and overall cost.

- 410/410S/410HT Stainless Steel – Alloy 410 is the basic martensitic stainless which will attain high mechanical properties after heat treatment. It has good impact strength, corrosion and scaling resistance up to 1200 F (649 C).

- 416/416HT Stainless Steel – Alloy 416 was the first free machining stainless steel. It is a heat treatable chromium steel with excellent machinability and non-galling characteristics. The alloy is magnetic in all conditions.

- 420 Stainless Steel – Alloy 420 is a general purpose heat treatable chromium steel which is a popular cutlery grade.

- 430 Stainless Steel – Alloy 430 is a basic ferritic non-heat treatable stainless steel. Its strengths are in ductility, formability, good corrosion and oxidation resistance, thermal conductivity and finish quality.

- 440C Stainless Steel – Alloy 440C is a high carbon martensitic stainless with moderate corrosion resistance good strength and the ability to obtain and keep excellent hardness (Rc 60) and wear resistance.

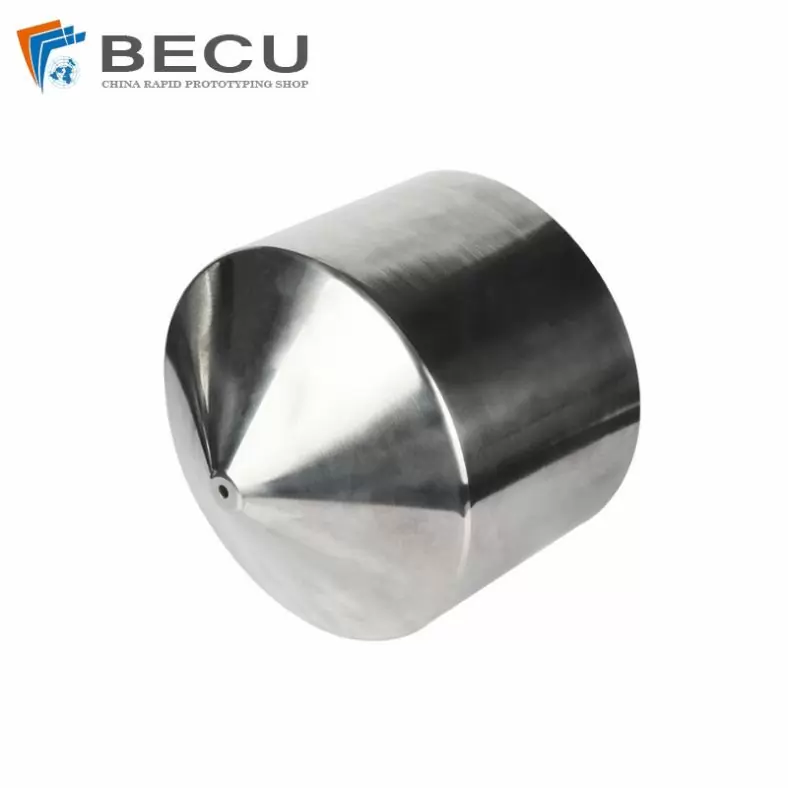

Stainless Steel Spinning Service – Spun Stainless Steel Suppliers & Company

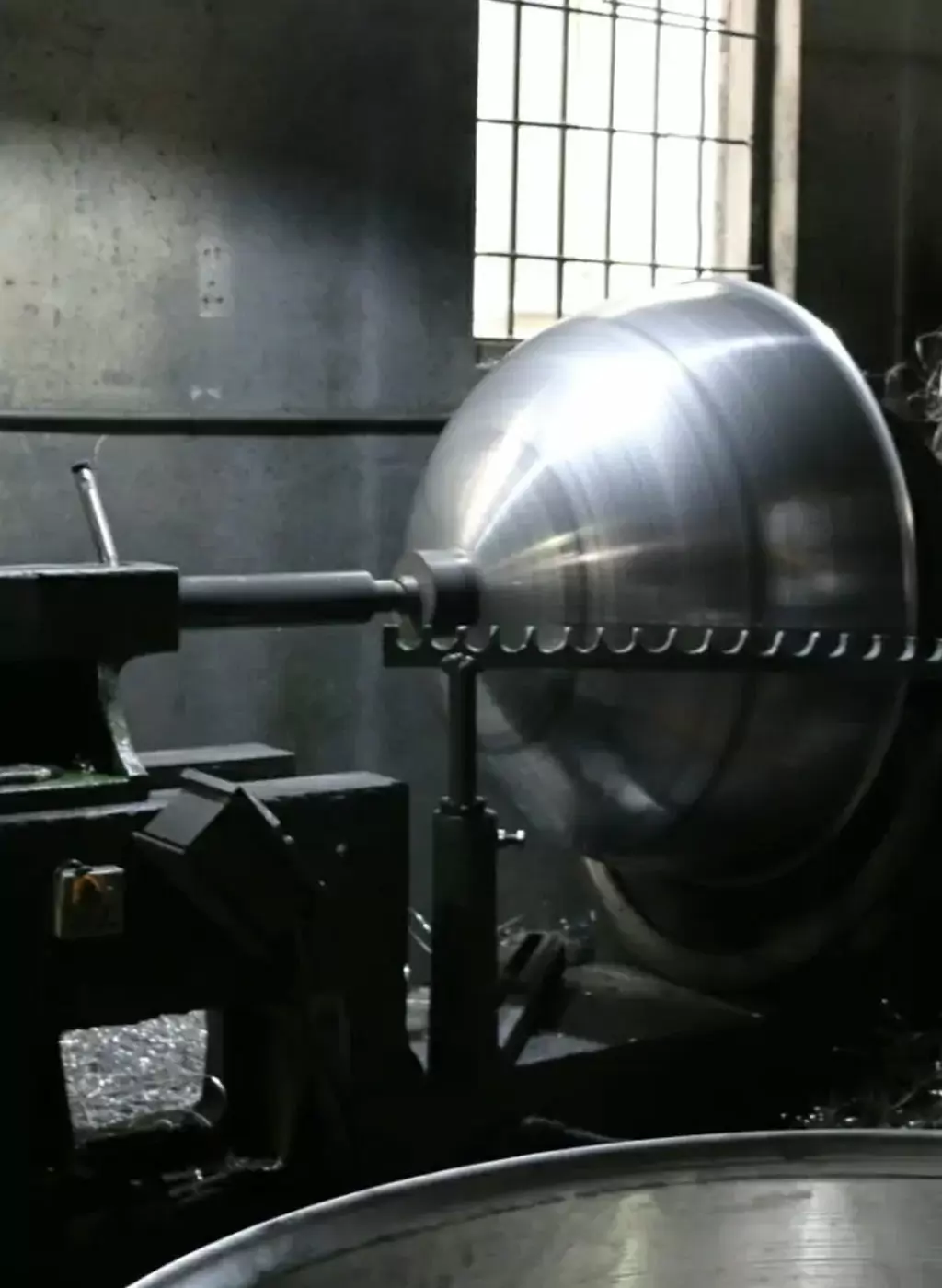

Spun stainless steel and manufacturing is one of the main services provided by Be-cu.com, and the stainless steel metal sheets are the primary materials of the products for diverse industries. From cooker projects to electronic accessories, our stainless steel metal spinning services will deliver custom stainless steel parts or spun product that fit your exact standards. Stainless steel cnc spinning parts are generally fabricated through processes including forming, lathe spinning, and rolling, brazing, punching, pressing, etc.Parts up to 60 inches in diameter, and thicknesses ranging from .012 to .190 inches can be fabricated within a tolerance of +/-0.005 inches.Be-cu(Pintejin Group) will also offer a full array of surface finishing services to achieve a unique appearance and effect according to your needs. With decades of years from metal machining to fabrication, Be-cu.com is a full-service company that provides almost any manufacturing service with well-equipped facilities and seasoned professionals.

The Advantage Of Stainless Steel Spinning

Metal spinning offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, stainless steel spinning tools are typically 10% of the cost.

- Shorter Lead Times – The stainless steel spinning process amounts to significantly shorter turnaround times – tools and spun components can be available within weeks rather than months.

- Maximum Design Flexibility – stainless steel spinning tools can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – stainless steel spinning produces smooth, durable objects without seams or welds, for parts require feature superior strength and great aesthetics.

Our Case Studies Gallery Of Spun Stainless Steel CNC Spinning

Put Be-cu.com’ experience to work for all of your stainless steel spinning and spin forming needs—from traditional manual aluminum spinning to cutting edge CNC stainless steel spinning. The spun stainless steel spinning process is perfect for a wide variety of industries that require consistent tolerances, fast turn-around, and uncompromising quality.