Titanium Laser Cutting

Titanium is a strong, lightweight metal that can be laser cut with precision. However, the laser cutting process of titanium is complex because of its high density and heat resistance. Titanium must be cut using the same tools and machines to be formed into precise parts. Additionally, the metal must be cooled quickly, so it does not become brittle.

The titanium also has a low melting point, requiring unique metallurgical processes to create alloys. One of these manufacturing services is titanium laser cutting. This highly automated process is one of the most versatile ways to manufacture titanium alloy parts. However, several factors come into play for laser cutting titanium alloy.. A titanium laser cutting manufacturer can help you achieve the quality, accuracy, and precision required for titanium cutting.

The Titanium Alloy Grades Of Metal Laser Cutting

There are a vast variety of grades of titanium alloys, and we mainly work with the following grades of titanium alloy to make custom laser cutting parts for our customers:

- Grades 1 to 4 of titanium are considered to be the purest. These grades are not alloyed and are in their original form. As the number of grade goes up, the yield strength and the tensile strength of the titanium increases. This means that the tensile and yield strength of grade 2 titanium is greater than that of grade 1, and so on. The strength-to-weight ratio of these grades is high. Moreover, they are lighter than steel.

- The grade 5 titanium alloy is also referred to as Ti 6-4, or Ti-6AL-4V, or Ti6Al4V, and is one of the most widely used alloys in various applications. The titanium grade 5 alloy is known for its high strength. It offers more resistance to high temperatures as compared to that offered by grade 2 titanium. This is the reason why this grade of the alloy is most commonly used in applications, such as chemical processing, medical, aerospace, marine, and so on.

- The titanium grade 9 alloy is known for its high strength. It has a tensile strength that is higher than that of a pure grade 2 titanium alloy. This better strength at room and elevated temperatures make this grade of the alloy more popular in a variety of applications. This alloy grade is also referred to as Ti-3AL-2.5V. The weldability of grade 9 titanium alloy is more as compared to that of grade 5 titanium alloy.

Titanium Laser Cutting Services – CNC Laser Cut Titanium Parts Suppliers & Manufacturer

Equally as strong as steel but 45 percent lighter, titanium is one of the most durable metals. This silvery-colored material gives a competitive edge to various processes, from welded pipes and valves to heat exchanges, airplanes, ocean-going vessels, and spacecraft.

Improve your application with titanium parts or assemblies from Be-cu.com. We are an ISO 9001:2015-certified laser cutting shop specializing in manufacturing precision components and constructing multifaceted upper-level products for challenging projects. The combination of advanced equipment, experienced personnel, and a quality-first mindset enables us to deliver a wide range of custom services that optimize client supply chains.

Our Titanium Laser Cutting Capabilities

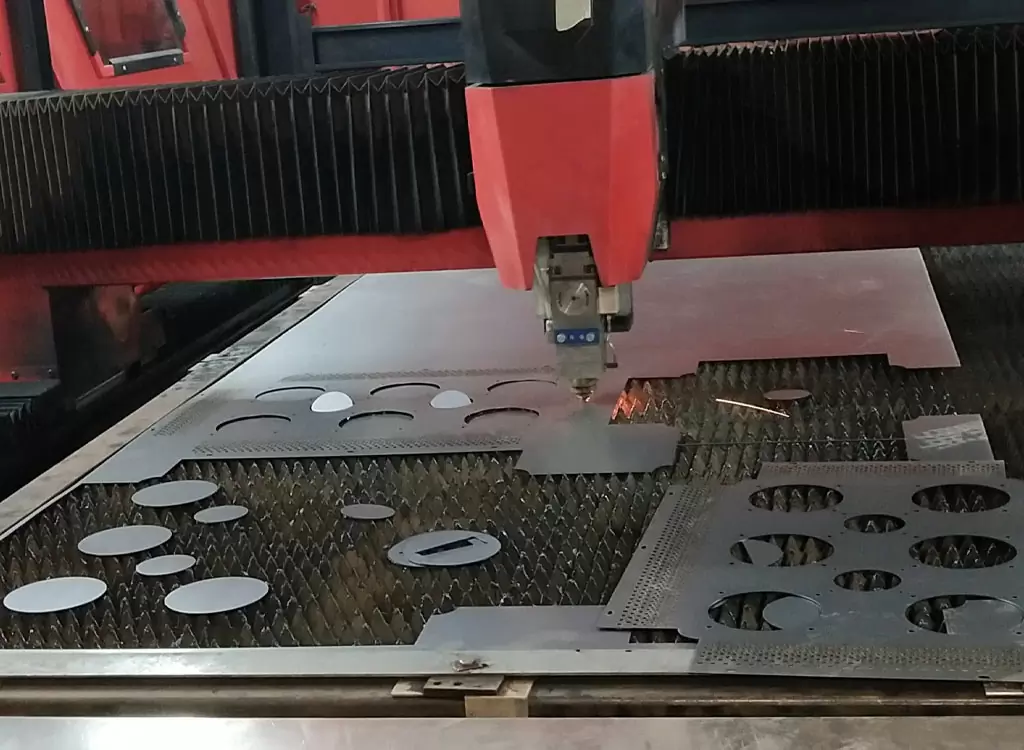

ISO 9001:2015 certified Titanium plate laser cutting & Titanium tube laser cutting services to eliminate burrs & secondary operations in fabricated tubing assemblies. Plate cutting to 1 in. thick, 60 in. x 120 in., tolerances to plus/minus .002 in., CAD/CAM nesting software increases sheet yield resulting in less material scrap, quantities from one piece to thousands.

Rapid laser inspection with 1st article inspection & reports, no tooling, reverse engineering capabilities. Secondary services include machining, aqueous cleaning, coping, beading, drilling, flattening, flaring, notching, piercing, slotting, swaging, threading, bar coding, brush & tumble deburring, chamfering, JIT-SPC, plating, powder coating, reverse engineering, packaging & assembly. ISO certified QC & inspections.

Why Use Our Titanium Laser Cutting Services

The Top 6 Reasons:

- No MOQ:One-off Titanium laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom Titanium laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Combine With Other Titanium Manufacturing Processes

Most laser shops will only give quotations for laser cutting as a standalone process. But when the quantity of new parts goes up to hundreds or more, you need a better solution for the best results. For some of these conplex parts, it is better not to cut them from a solid block at all, but to use tool-based fabrication or edm cutting assisted by milling.

When making Titanium cutting parts, Be-cu.com offers several ways to combine precision laser cutting with other manufacturing processes in order to create more complex parts that can be made in large quantities. These process combinations can maximize the functionality of Titanium while still enjoying the benefits of other production processes.

CNC Bending,Welding, Laser Engraving, Metal Etching,Precision machining, stamping, EDM, Wire Cutting and more can all be complemented with laser cutting to make better Titanium components. No matter the test and no matter what properties are required.

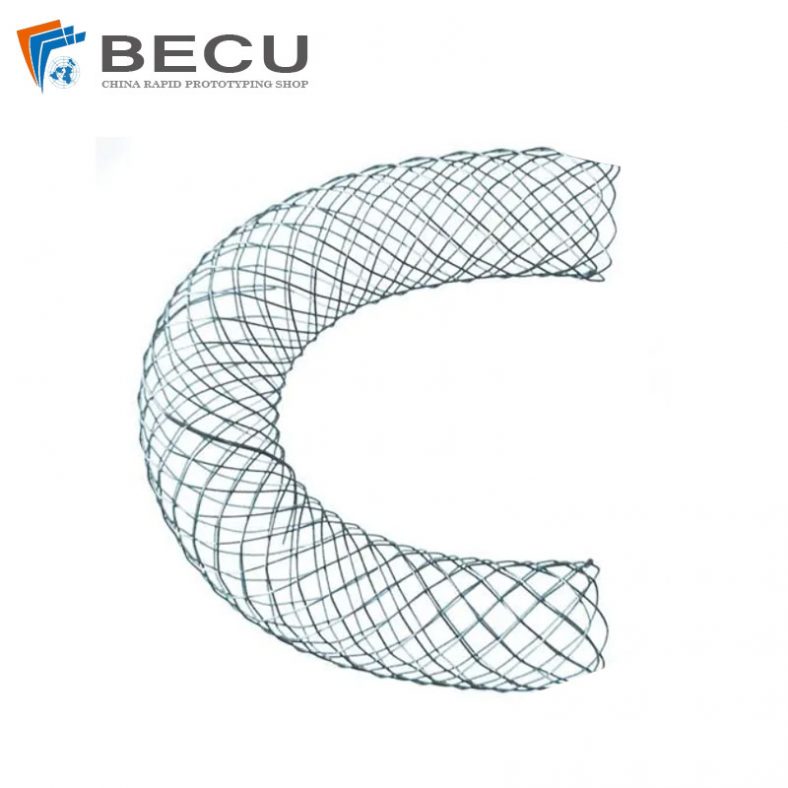

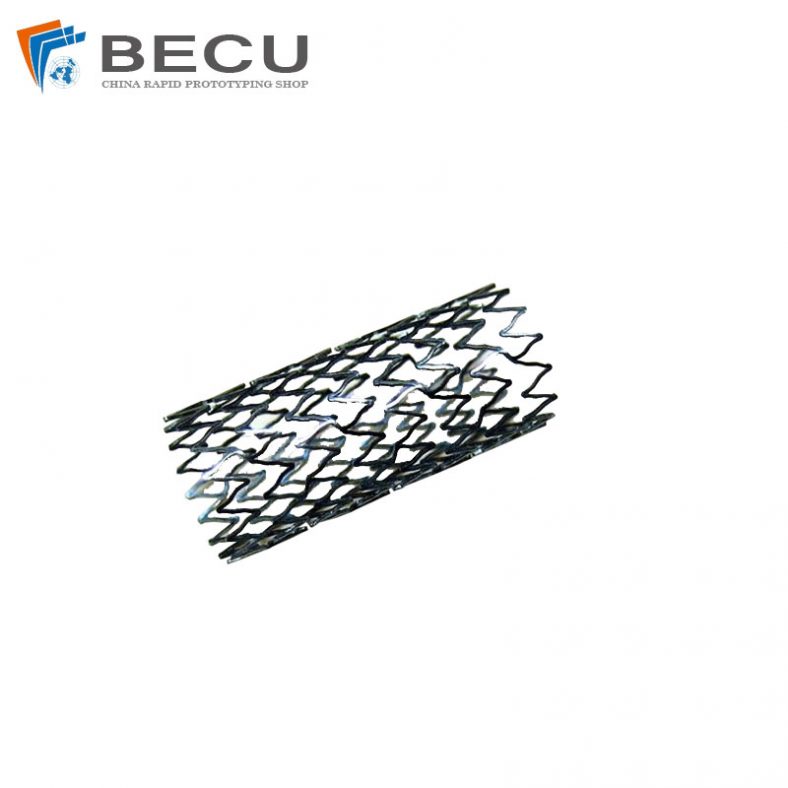

Our Case Studies Gallery Of Titanium Laser Cutting

Titanium laser cutting produces durable, end-use Titanium parts with a wide selection of Titanium materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy, robotics and more.Compared with traditional laser cutting companies, we have a large amount of precision machines, so we can do precision post-machining in house.Send your CAD files or inquiry to us, a fast, free online laser cutting quote of required Titanium components will be back. Get your Titanium Laser Cut Parts into fabrication in the shortest time.