Dental Teeth

- Product name: Dental Teeth

- No+Color: Custom

- Surface treatment: Custom

- Product material: Ti-6Al-4V

- Proofing cycle: 7 days(100000 pcs/M)

- Machining Factory: BE-CU.com

- Production Process: SLM 3D Printing Service

- Size:According To Customer Drawings

The application of 3D printing technology in fabricating dental teeth using titanium alloys represents a significant advancement in the field of dentistry. This innovative approach combines the precision of 3D printing with the unique properties of titanium alloys to create highly durable, biocompatible dental restorations. Let’s explore the process, advantages, and implications of 3D printing titanium alloy dental teeth.

The Process of 3D Printing Titanium Alloy Dental Teeth

The production of 3D printed dental teeth involves several key steps:

- a. Digital Scanning and Design: The process begins with the digital scanning of the patient’s teeth or the use of intraoral scanners to capture the desired tooth shape. The scanned data is then converted into a digital 3D model using specialized dental CAD software.

- b. Material Selection: Titanium alloys, such as Ti-6Al-4V, are commonly used in dental applications due to their excellent biocompatibility, high strength, and corrosion resistance. The 3D printing process utilizes titanium alloy powders specifically designed for dental applications.

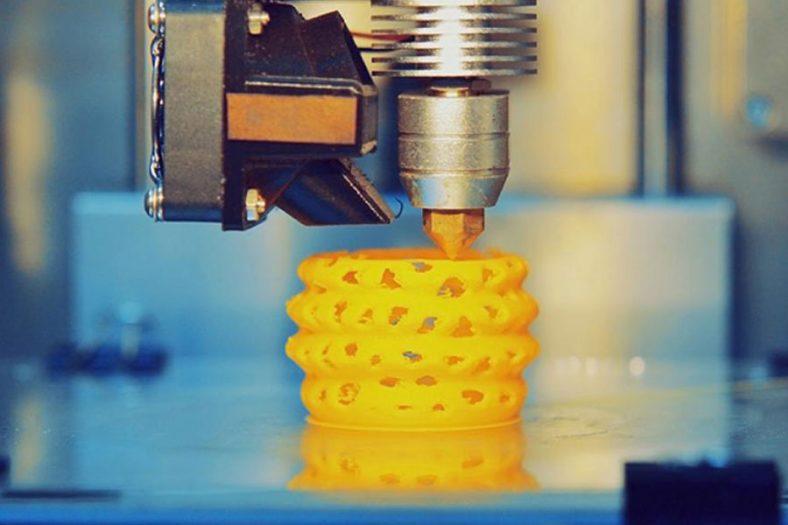

- c. 3D Printing (Selective Laser Melting or Electron Beam Melting): The 3D printing process commences with the selective melting of the titanium alloy powder using a laser or electron beam. Layer by layer, the dental teeth are gradually built up according to the digital 3D model, ensuring precise customization and accurate replication of the patient’s teeth.

- d. Post-Processing and Finishing: After the 3D printing is complete, the dental teeth undergo post-processing treatments. This may include removing support structures, heat treatment to optimize material properties, and surface finishing processes such as polishing or coating to ensure biocompatibility and aesthetics.

Advantages of 3D Printed Titanium Alloy Dental Teeth

The use of 3D printing technology in fabricating dental teeth from titanium alloys offers several advantages:

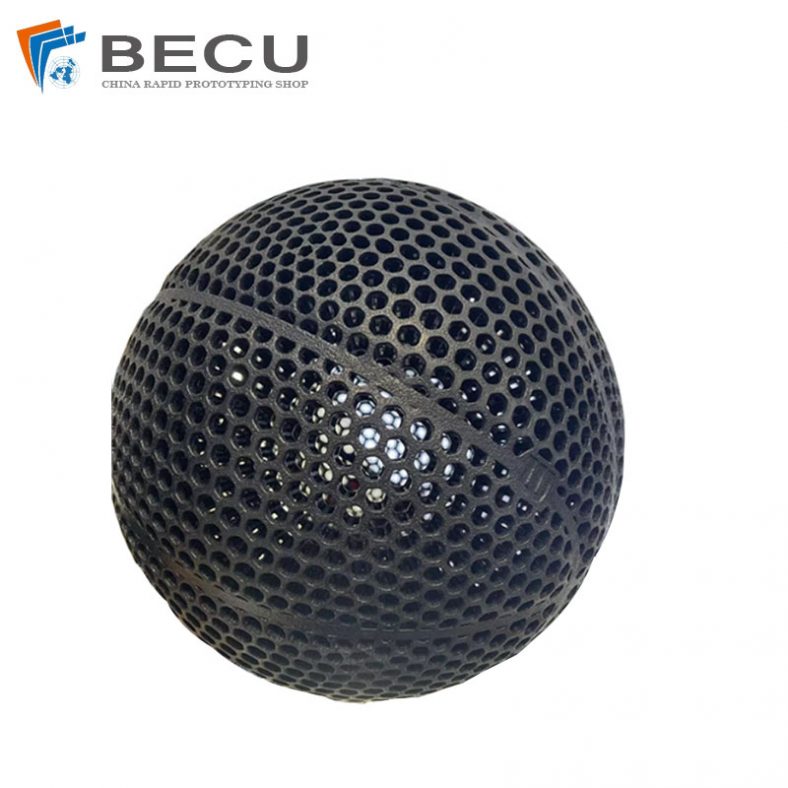

- a. Customization and Precision: 3D printing enables the creation of highly customized dental teeth tailored to each patient’s unique dental anatomy. The digital design and 3D printing process ensure precise replication of tooth shape, size, and occlusion, leading to improved fit and aesthetics.

- b. Biocompatibility and Durability: Titanium alloys are biocompatible, meaning they are well-tolerated by the body and have a low risk of adverse reactions. Additionally, titanium alloys offer excellent mechanical strength and corrosion resistance, ensuring long-term durability and stability of dental restorations.

- c. Reduced Material Waste: 3D printing allows for the precise use of materials, minimizing waste compared to traditional manufacturing methods. This contributes to sustainability and cost-effectiveness in dental laboratories.

- d. Faster Production Time: 3D printing eliminates the need for labor-intensive manual processes and the reliance on multiple steps involved in traditional dental restorations. This results in reduced production time, allowing for quicker turnaround and improved patient satisfaction.

Implications and Applications

The use of 3D printed titanium alloy dental teeth has significant implications in various dental applications:

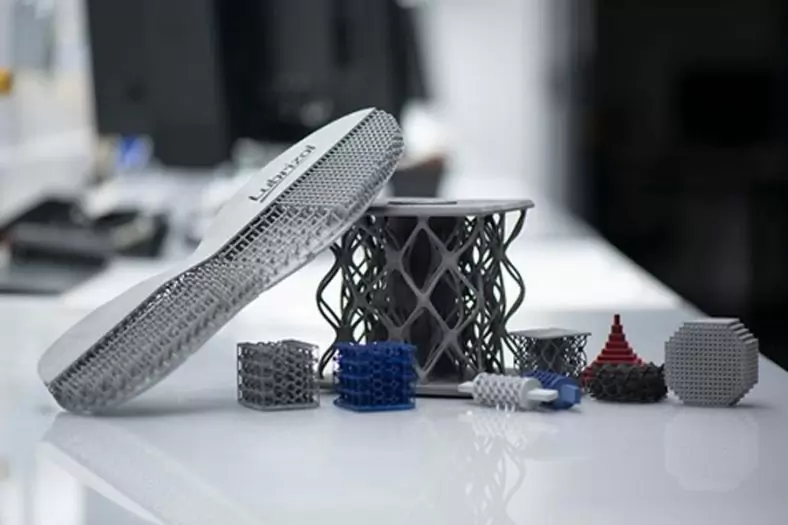

- a. Dental Restorations: 3D printed titanium alloy dental teeth can be used for various restorations, including crowns, bridges, and implant-supported prosthetics. Customized designs ensure optimal fit, functionality, and aesthetics.

- b. Prosthodontics: 3D printed dental teeth are utilized in prosthodontics to replace missing teeth, providing patients with functional and natural-looking dental restorations.

- c. Orthodontics: 3D printed dental teeth play a role in orthodontic treatments, such as clear aligners or indirect bonding trays. Customized dental teeth aid in precise tooth movement and treatment planning.

- d. Dental Education and Training: 3D printing technology allows for the production of dental models and teeth for educational purposes, enabling dental students and practitioners to practice procedures and gain hands-on experience.

The utilization of 3D printing technology in fabricating dental teeth using titanium alloys showcases the transformative potential of additive manufacturing in dentistry. Customization, biocompatibility, durability, and reduced production time contribute to improved patient outcomes and enhanced dental care. As 3D printing technology continues to advance, we can expect further advancements in patient-specific dental restorations, transforming the field of dentistry and revolutionizing the way dental treatments are delivered.

3D Printing Titanium Alloy Dental Teeth Service

Be-Cu prototype 3D Printing Titanium Alloy Dental Teeth services provide the most accurate type of form prototype for the verification of any design before production. Its high accuracy and fine surface finish makes it the best choice for designer models for medical prototype.

Why Choose 3D Printing Titanium Alloy Dental Teeth Service?

- – No minimum order quantity

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

- – A wide selection of metal or plastic materials

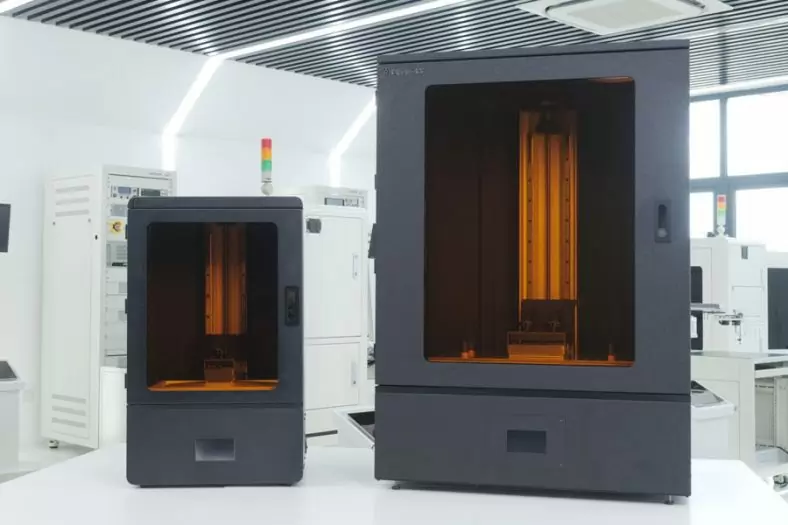

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

The Specifications Of 3D Printing Titanium Alloy Dental Teeth

| Item Name | Metal 3D Printing |

| Material | Ti-6Al-4V Titanium |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.