Mobile Phone Buttons

- Product Name: Mobile Phone Buttons

- No+Color:Custom

- Surface Treatment: Custom

- Product Material: Grade 5 Titanium Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application: Titanium Machining

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Electronic Machining Parts

- Production Process: Telecom Cnc Machining

- Size: According To Customer’s Drawings

High-Quality 4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

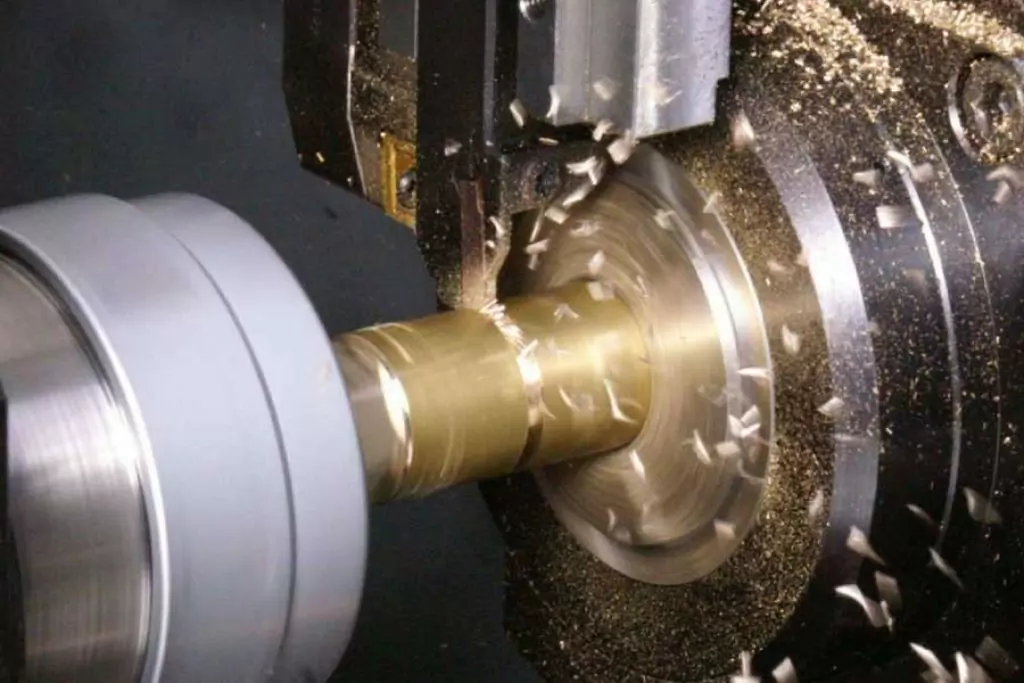

Machining Titanium Grade 5 (Ti-6Al-4V) with a 4-axis CNC machining to produce mobile phone buttons requires careful consideration of the material’s properties and the machining process. Titanium Grade 5 is known for its high strength, low weight, and excellent corrosion resistance, but it can be challenging to machine due to its hardness.

At Be-Cu.com, we don’t merely operate machinery; we craft precision. With a remarkable tolerance level of up to +/- 0.0002 in. (±0.005mm), we work on a diverse range of mobile phone buttons.

The Advantages Of 4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of 4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

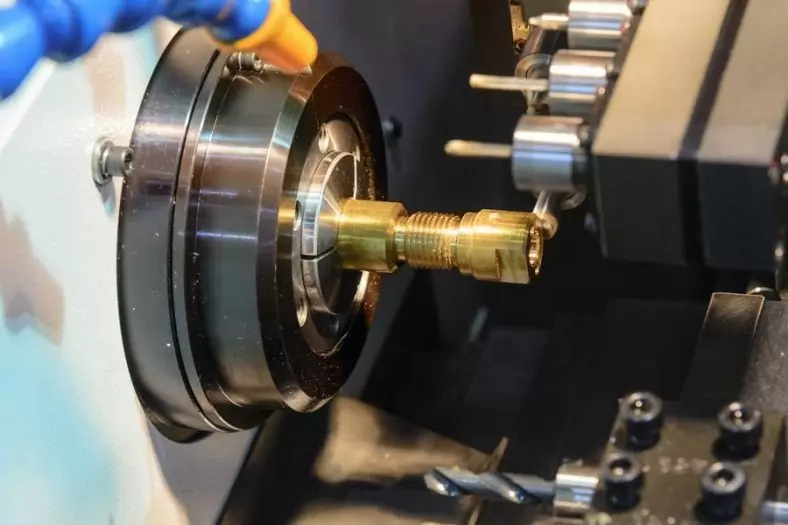

| Material | Grade 5 Titanium Alloy |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

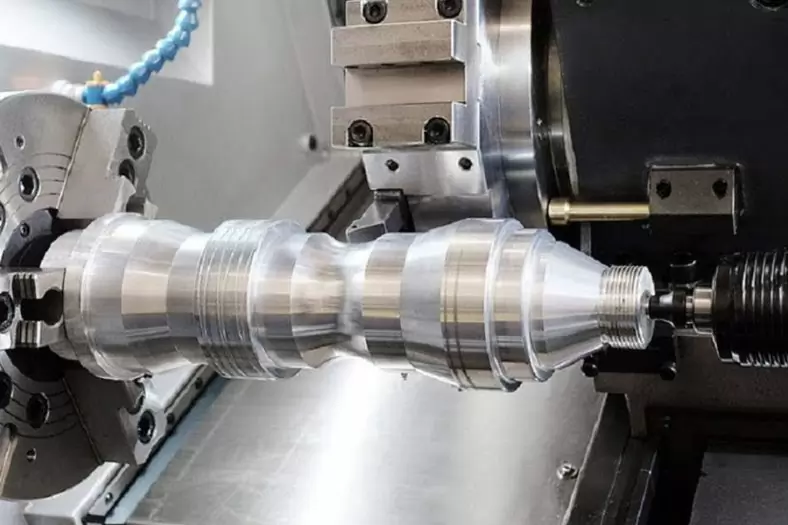

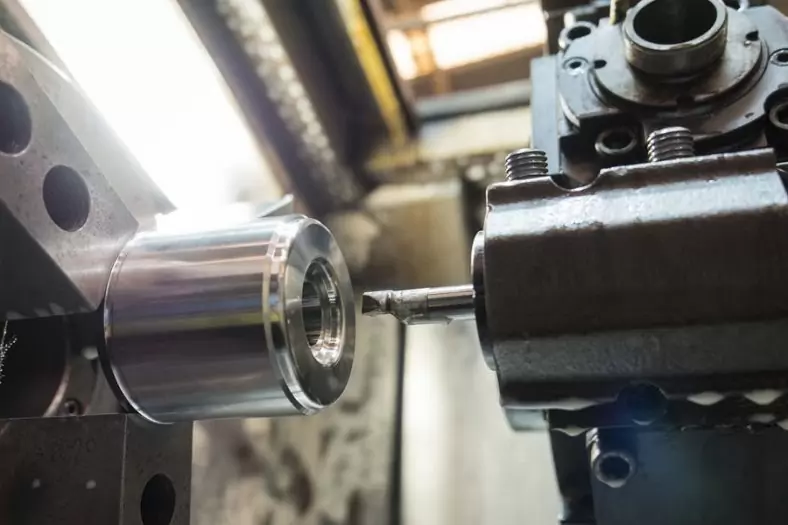

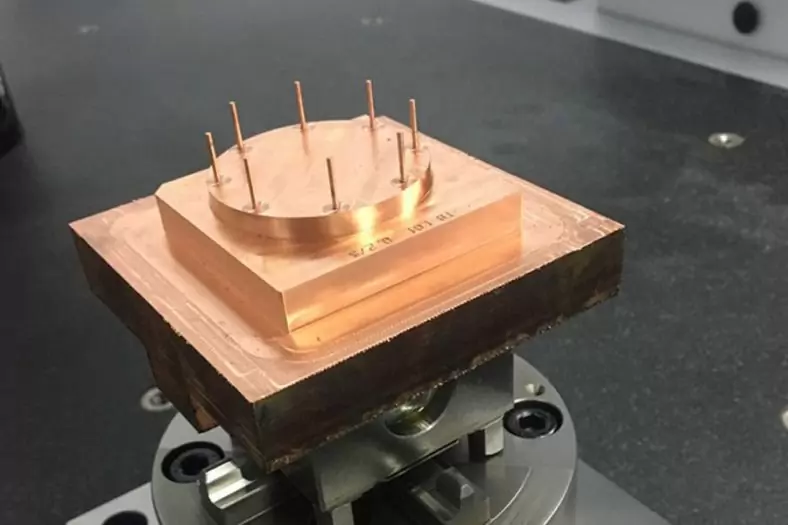

| Main Process | Swiss Machining,CNC Turning ,Cnc Milling,Cnc Drilling, 5 Axis Cnc Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Medical |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Turning Company

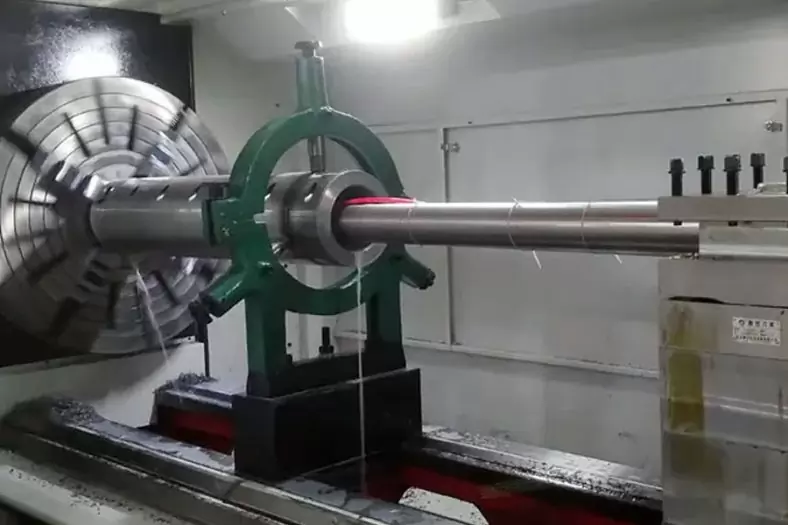

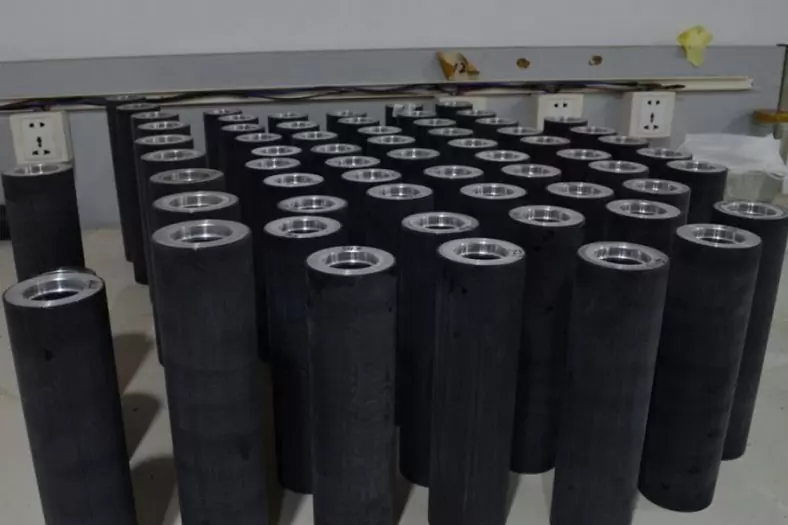

Be-cu.com is an experienced precision CNC turning services supplier, manufacturer, exporter in China, has been specialized in offering best OEM CNC lathe services for superior quality low cost CNC turning parts, CNC lathe parts or high precision machined components with the operation of an impressive range of state-of-the-art turning machines, such as washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc. Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to reach your requirements. Our custom cnc machining services ensure that our customers receive the highest quality CNC turned parts.

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

Precision Turning Solid Wood Dice

-

Custom Wood Chess Board, Sets And Pieces

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

Precision Turning 20° Acrylic Downlight Reflector

-

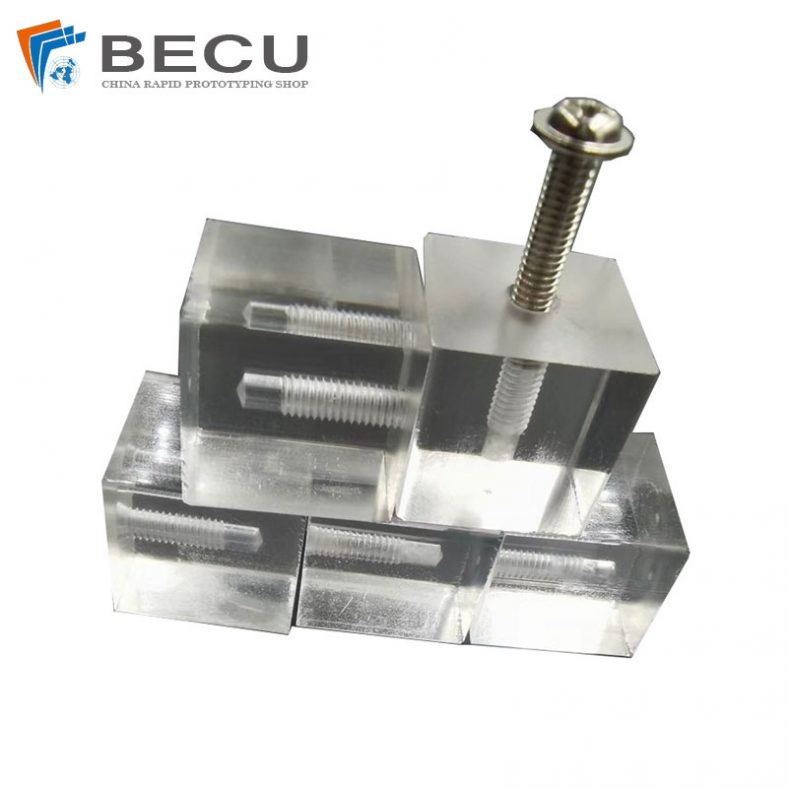

Transparent Acrylic Faceted Cube Threaded Clamp