Titanium Chemical Etching

Titanium is a rare metal with the characteristics of light weight, high strength, and corrosion resistance to wet chlorine gas. Titanium etching is to corrode titanium through chemical solution, and process it into titanium mesh, surface engraved lines, LOGO and plate-shaped titanium alloy parts. The metal chemical etching process has different characteristics. Change the physical properties of titanium alloy, the processed parts are smooth without burrs, and the etching precision is high.

Titanium Etching is usually a titanium plate with a thickness of 0.03~2.0mm. The minimum aperture of the etching mesh is normally 1.5 times that of the material, and the etching accuracy can be ±0.08mm.

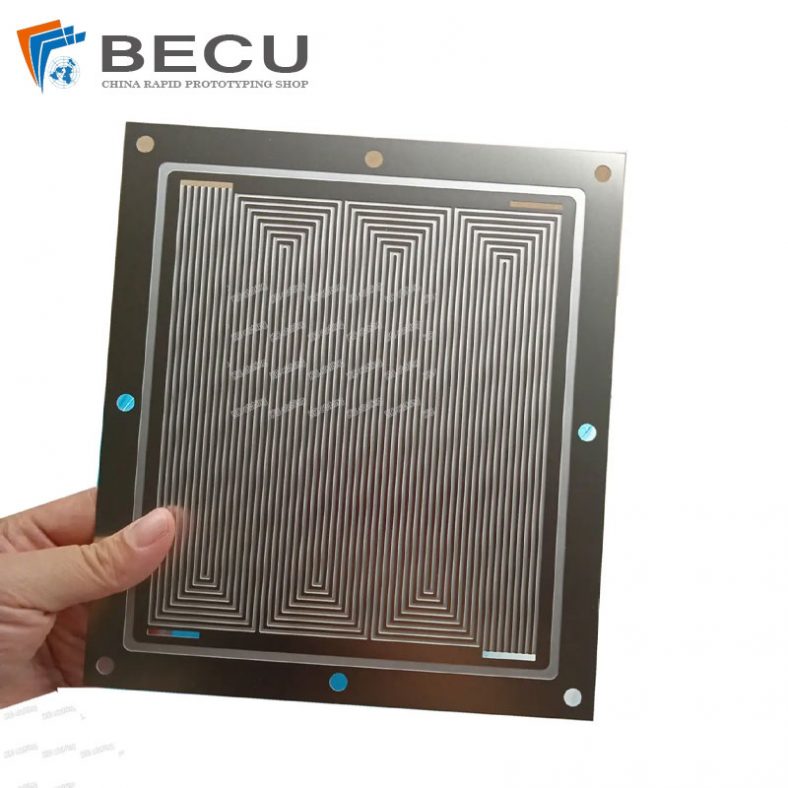

With the upgrading of etching technology, more and more titanium alloy parts are completed by etching process. At present, titanium etched metal bipolar plates with hydrogen fuel cells, mobile phone folding screens, titanium mesh used in aerospace medical equipment, etc. .

What Is Titanium Etching

Titanium etching is a high-precision etching process that uses titanium or titanium alloys as raw materials, adopts scientific etching processing technology, and etches various titanium products and titanium alloy products on the surface of titanium plates according to customized design drawings.

The Properties Of Titanium

Titanium is a silver-white metal, which is also considered a rare metal because it is dispersed in nature and difficult to extract. The most common compound of titanium is titanium dioxide, which can be used to make white pigments. Titanium etched parts are widely used in many industries.

- Light Weight.

- High Strength. We provide you with customized metal parts, using titanium etching process, not easy to deform.

- Metallic Luster. Our titanium etching process not only provides a high-quality product, but also guarantees the luster of the metal parts.

- Resistant To Wet Chlorine Corrosion. It does a good job of preserving parts that are not corroded by chemical solutions during titanium etching.

The Applications Of Titanium Etching

Titanium etched parts and plates are widely used in the decoration of high-level public facilities such as shopping malls, hotels, supermarkets, and KTVs, as well as cutting-edge equipment in high-tech industries such as aerospace, military, medical, marine, and underwater operations.

Titanium Etching Service – Titanium Chemical Etching Company

As you may have noticed, choosing the most suitable titanium for your product depends on the properties and applications you want. If you are trying to develop products for medical applications, you may want to choose the grade 23 titanium. Alternatively, if you are looking for a piece with excellent performance at elevated temperatures, you should consider working with grade 6 titanium.

Be-cu offers a wide range of custom online titanium etching services, including precision etching titanium alloy and toolings making and others. We chemically etch thousands of titanium-based components each month for a wide range of engineering applications from the automotive, electronics and precision engineering sectors.If you want expert support from a vendor you can trust, look no further than the precision etching services offered by Be-cu.com for your next titanium project.

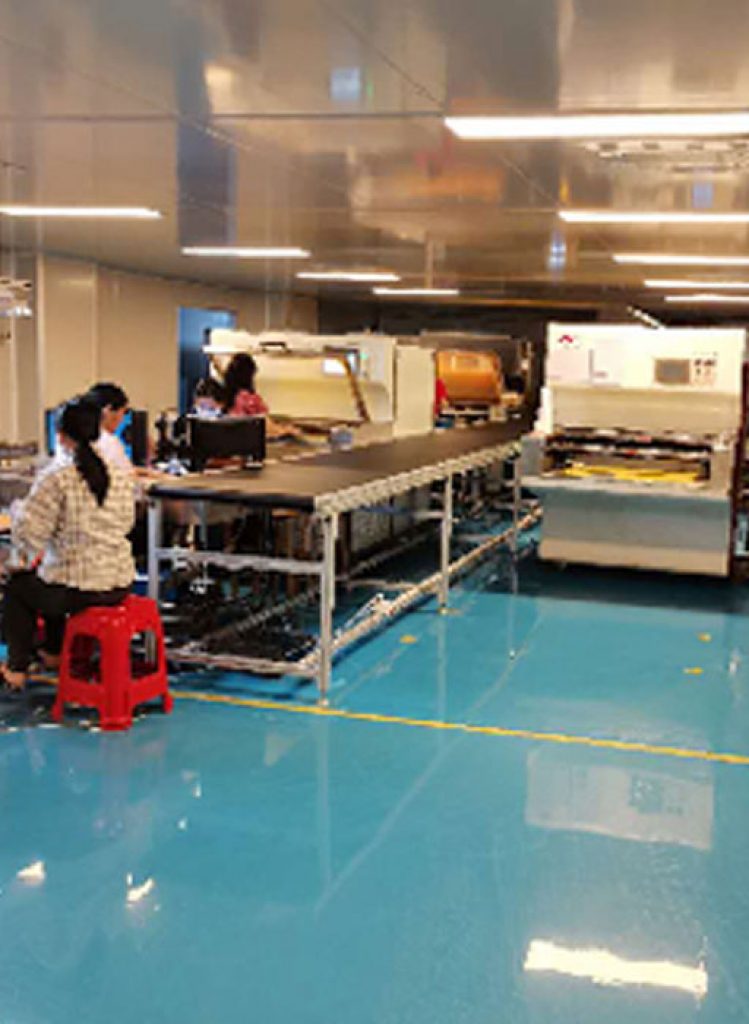

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

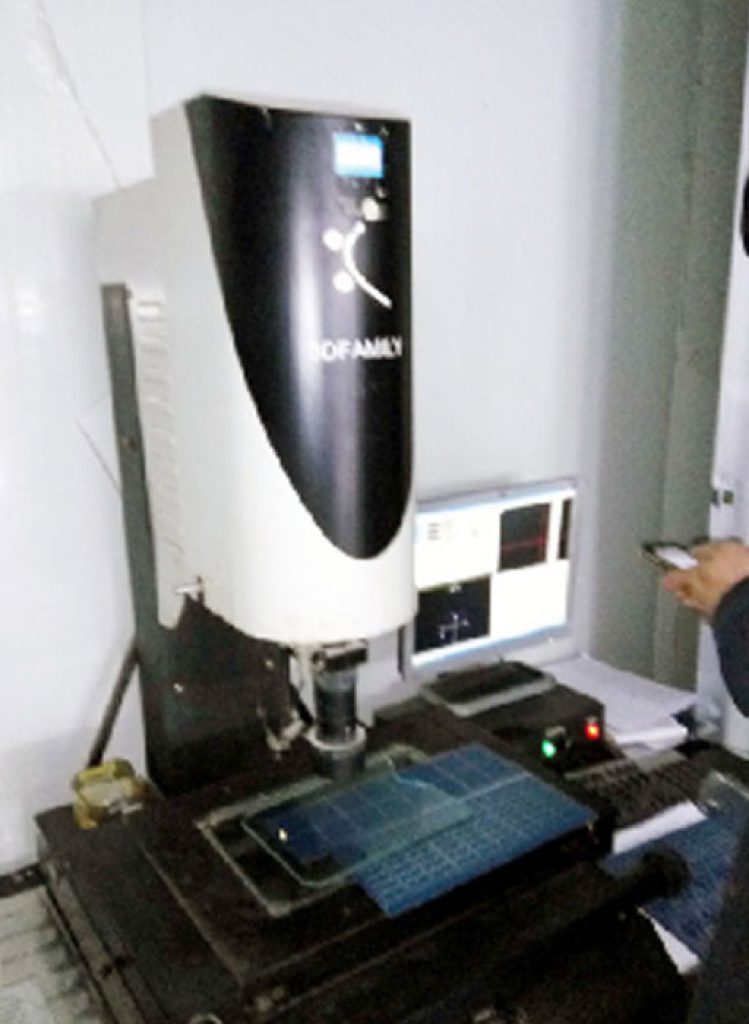

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

Titanium Chemical Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

Inspection For Etching

Exposure

Titanium Chemical Etching Parts & Case Studies In China

As one of professional Titanium Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the titanium material characteristics. So we can offer you the best etching titanium solution according to your requirements of Titanium parts and products.

-

Metal Etched Hydrogen Fuel Cell Metal Bipolar Plates

-

Precise Etching Stainless Steel 316 High-Speed Hair Dryer Networks

-

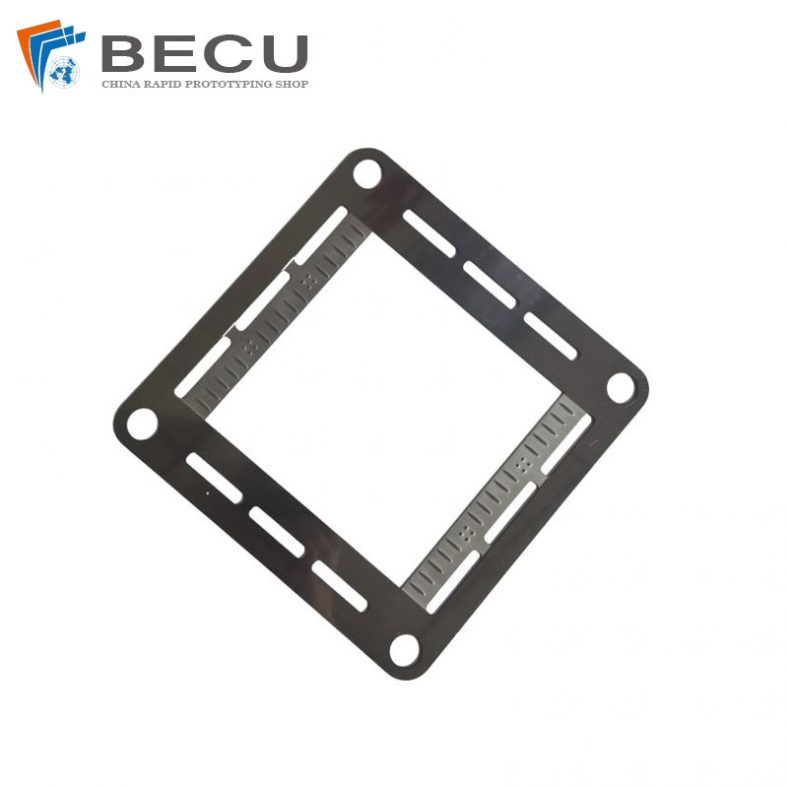

Chemical Etching Stainless Steel 316 Bipolar Flow Plates

-

Laser Cut And Etching 303 Jewelry Pendant

-

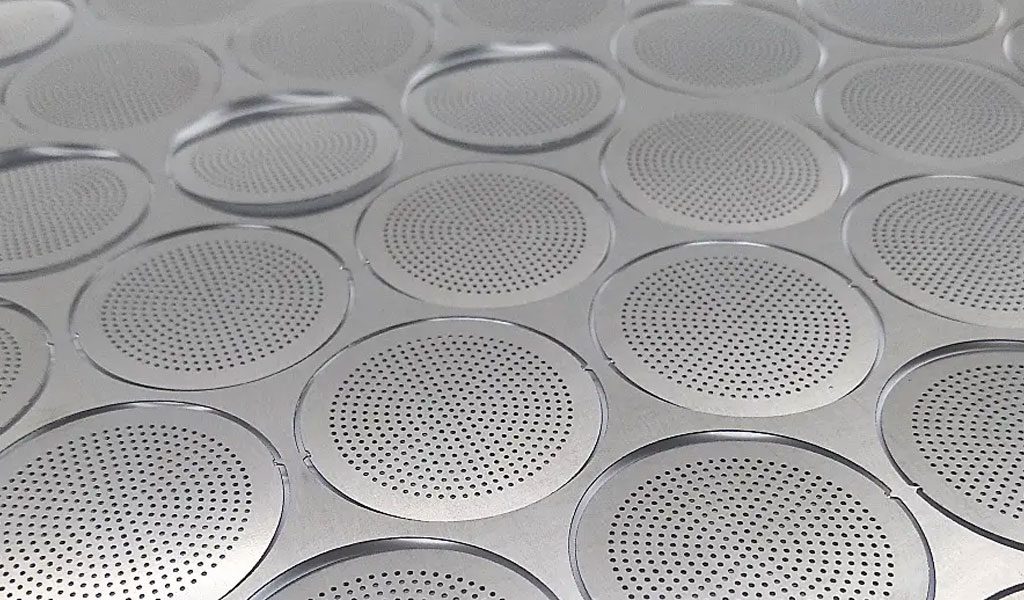

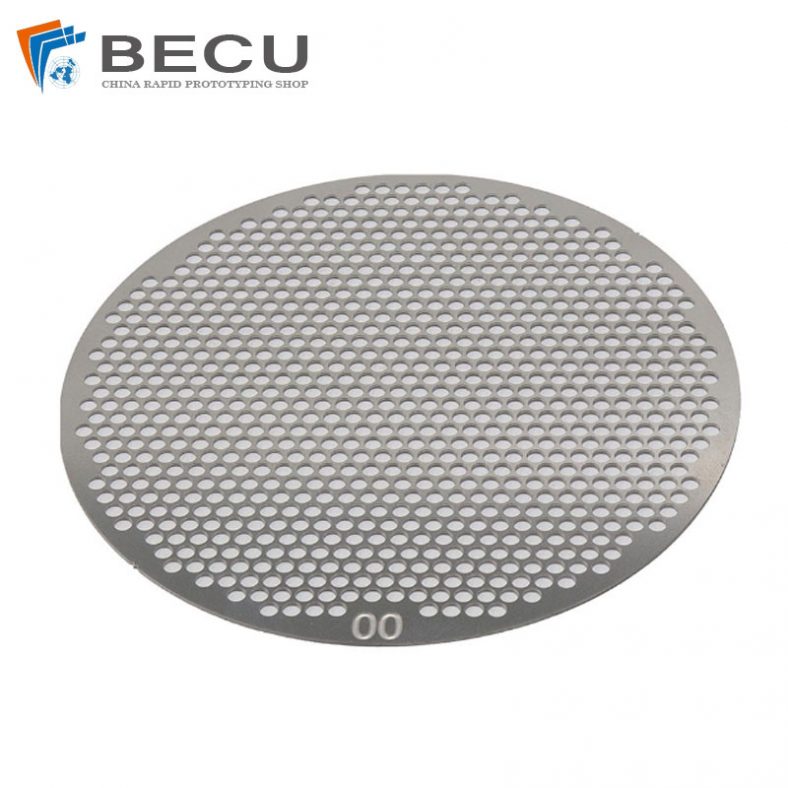

Photo Chemical Etching Microporous Dust Filter For Automotive Speaker

-

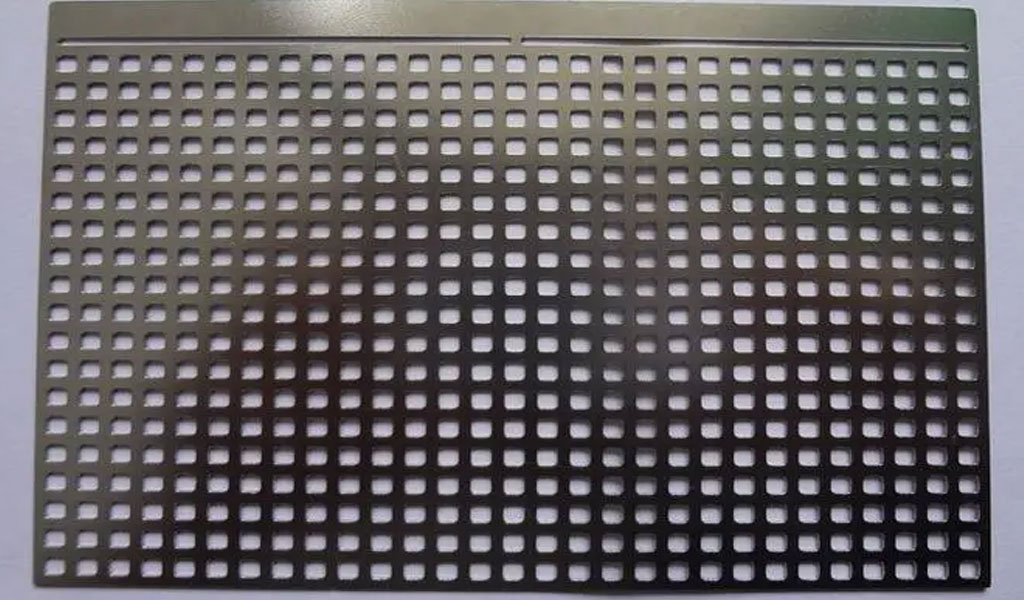

Precision Etching Automotive Audio Grille

-

Metal Etching 5 Inch Round Car Horn Protection Net

Surface Finishing Options for Titanium Chemical Etching

Parts made using photo etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

Online Cooperate With Titanium Etching Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision etching and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.