Sacroiliac Screws

- Product name: Bone Nail

- No+Color: Custom

- Surface treatment: Custom

- Product material: Ti-6Al-4V

- Proofing cycle: 7 days(100000 pcs/M)

- Machining Factory: BE-CU.com

- Production Process: SLM 3D Printing Service

- Size:According To Customer Drawings

The application of 3D printing technology in fabricating sacroiliac screws using Ti-6Al-4V titanium alloy represents a significant advancement in the field of orthopedic surgery. This innovative approach combines the precision and customization capabilities of 3D printing with the exceptional mechanical properties of Ti-6Al-4V to create high-performance sacroiliac screws. Let’s explore the process, advantages, and implications of 3D printing Ti-6Al-4V sacroiliac screws.

The Process of 3D Printing Ti-6Al-4V Sacroiliac Screws

The production of 3D printed sacroiliac screws involves several key steps:

- a. Patient-Specific Design: The process begins with the utilization of medical imaging, such as CT scans or MRI, to capture the patient’s sacroiliac joint anatomy. Using specialized software, a 3D model of the patient’s joint is created, allowing for the design of patient-specific sacroiliac screws.

- b. Material Selection: Ti-6Al-4V is a titanium alloy widely used in medical applications due to its excellent biocompatibility, high strength, and corrosion resistance. The 3D printing process utilizes Ti-6Al-4V powder specifically designed for additive manufacturing.

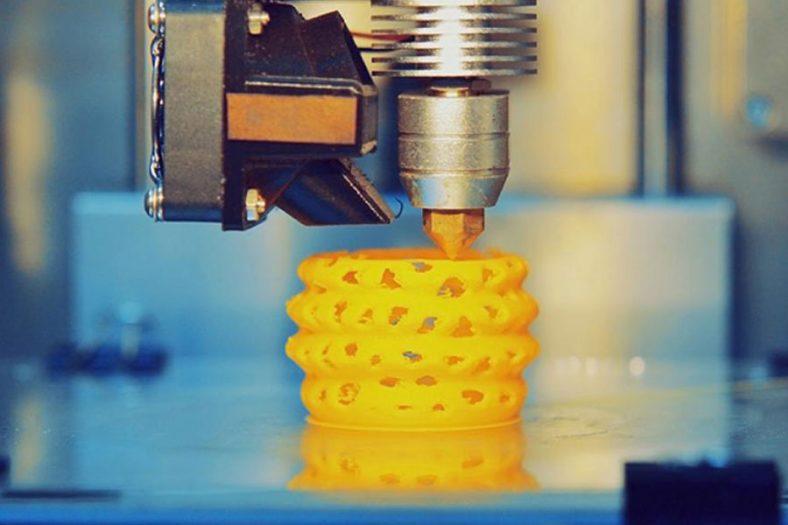

- c. 3D Printing (Selective Laser Melting or Electron Beam Melting): The 3D printing process commences with the selective melting of the Ti-6Al-4V powder using a laser or electron beam. Layer by layer, the sacroiliac screws are gradually built up according to the patient-specific 3D model, ensuring precise customization and accurate fit.

- d. Post-Processing and Finishing: After the 3D printing is complete, the sacroiliac screws undergo post-processing treatments. This may include removing support structures, heat treatment to optimize mechanical properties, and surface finishing processes such as polishing or coating to improve biocompatibility.

Advantages of 3D Printed Ti-6Al-4V Sacroiliac Screws

The use of 3D printing technology in fabricating sacroiliac screws from Ti-6Al-4V offers several advantages:

- a. Customization and Patient-Specific Design: 3D printing enables the creation of patient-specific sacroiliac screws tailored to each individual’s sacroiliac joint anatomy. This customization ensures optimal fit, stability, and reduced risk of complications.

- b. Biocompatibility and Mechanical Properties: Ti-6Al-4V is a biocompatible material widely used in orthopedic implants. The mechanical properties of Ti-6Al-4V, including high strength, excellent fatigue resistance, and low modulus of elasticity, make it well-suited for load-bearing applications such as sacroiliac screws.

- c. Reduced Material Waste and Cost-Effectiveness: 3D printing allows for precise material usage, minimizing waste compared to traditional manufacturing methods. This not only contributes to cost-effectiveness but also promotes sustainability in healthcare.

- d. Faster Production Time and Surgical Efficiency: 3D printing eliminates the need for custom tooling or molds, reducing lead times in the production of sacroiliac screws. This can translate to faster availability and improved surgical efficiency.

Implications and Applications

The use of 3D printed Ti-6Al-4V sacroiliac screws has significant implications in the field of orthopedic surgery:

- a. Sacroiliac Joint Fusion: 3D printed sacroiliac screws can be used in sacroiliac joint fusion procedures to provide stability and promote bone fusion. Customized screws offer an optimal fit and maximize the chances of successful fusion.

- b. Minimally Invasive Surgeries: The customization capabilities of 3D printed sacroiliac screws can benefit minimally invasive surgical techniques. Smaller incisions can be made, reducing tissue trauma and improving patient recovery.

- c. Revision Surgeries: 3D printed sacroiliac screws can be particularly valuable in revision surgeries, where standard off-the-shelf screws may not be suitable due to anatomical variations. Customized screws ensure proper fit and alignment, enhancing surgical outcomes.

3D Printing Ti-6Al-4V Sacroiliac Screws Service

The utilization of 3D printing technology in fabricating sacroiliac screws using Ti-6Al-4V titanium alloy offers significant advantages in orthopedic surgery. The customization, biocompatibility, mechanical properties, and cost-effectiveness of 3D printed sacroiliac screws contribute to improved patient outcomes and surgical efficiency. As 3D printing technology continues to advance, we can expect further advancements in patient-specific orthopedic implants, transforming the field of orthopedic surgery and revolutionizing the way sacroiliac joint procedures are conducted.

Be-Cu prototype 3D Printing Ti-6Al-4V Sacroiliac Screws services provide the most accurate type of form prototype for the verification of any design before production. Its high accuracy and fine surface finish makes it the best choice for designer models for medical prototype.

Why Choose 3D Printing Ti-6Al-4V Sacroiliac Screws Service?

- – No minimum order quantity

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

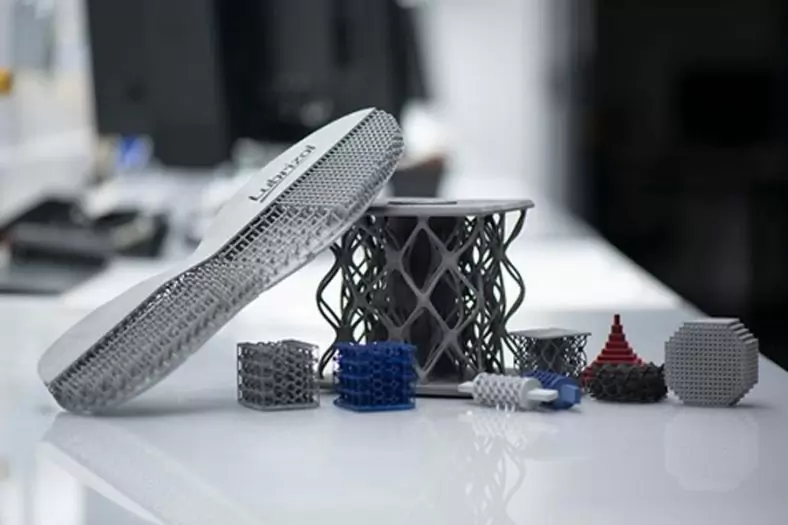

- – A wide selection of metal or plastic materials

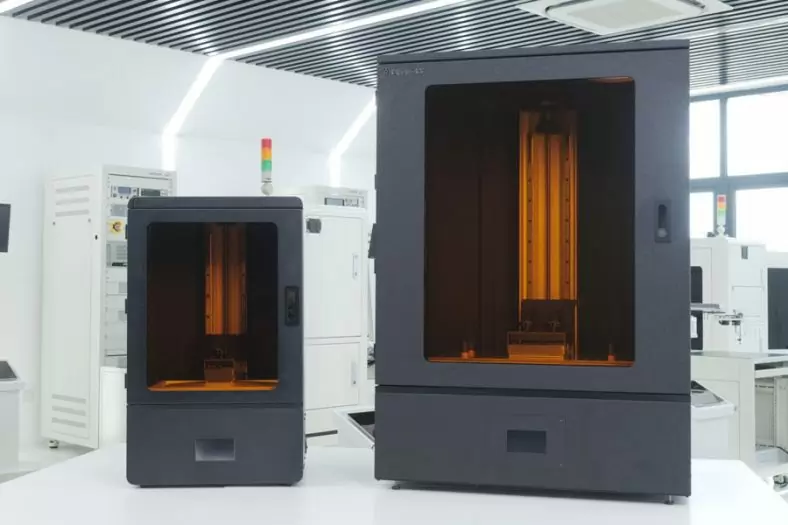

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

The Specifications Of 3D Printing Ti-6Al-4V Sacroiliac Screws

| Item Name | Metal 3D Printing |

| Material | Ti-6Al-4V Titanium |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.