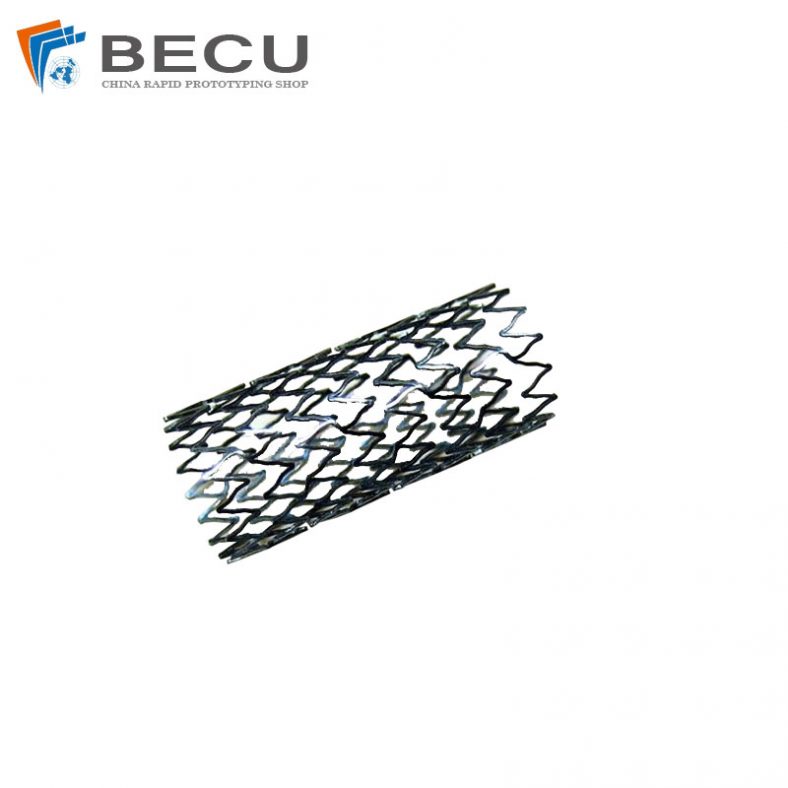

Valve Stent Laser Cutting

- Material: Nickel-Titanium Alloy

- Custom Process: Micro Laser Cutting

- Other Process: Drilling And Cutting

- Casting surface roughness: Ra6.3-800

- Annual Volume: 100,000 per year

- Size: Custom

- Application: Medical Laser Cutting

- Precision: +/-0.1mm

- Keyworld: Laser Cutting Titanium

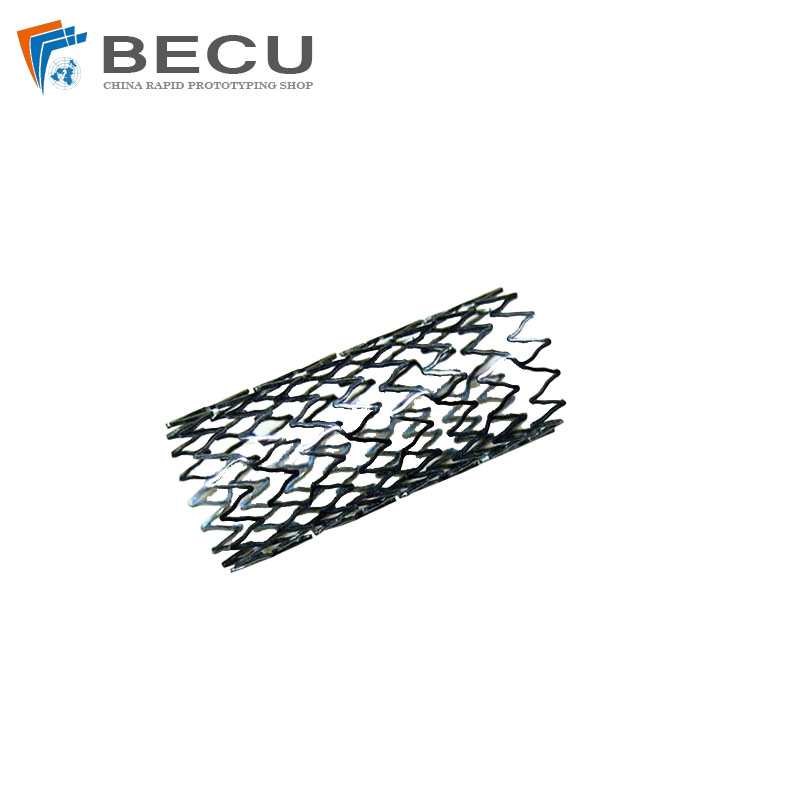

High-Quality Cutting Stents For Carrying Valves And Venous Valve Replacement Devices

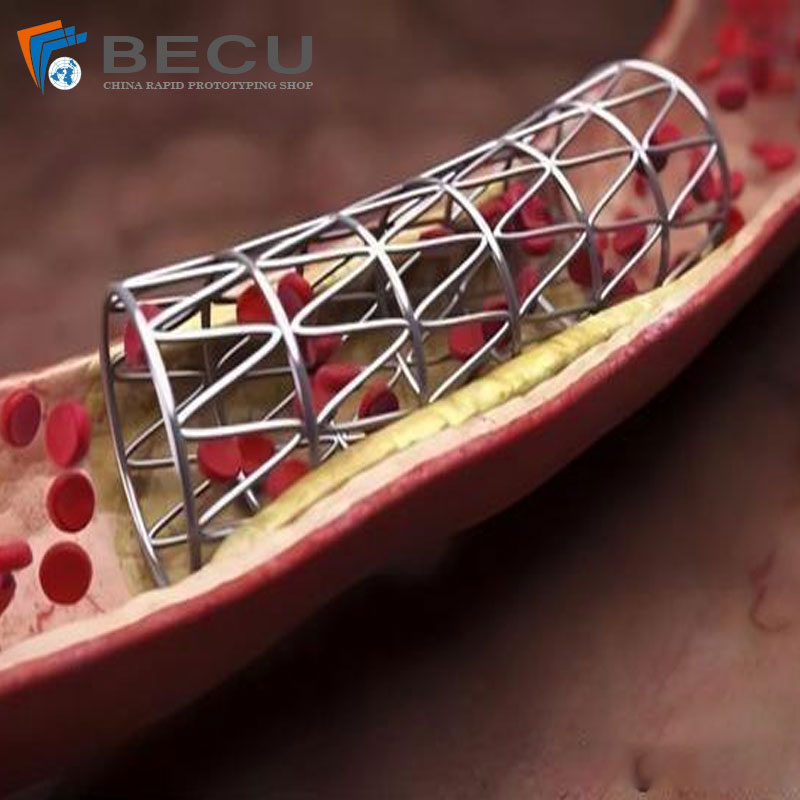

Stents are commonly used medical devices designed to support or reinforce various biological structures within the body. They are used in different medical procedures to treat conditions such as blocked arteries, weakened blood vessels, or narrowed passageways.

In the context of carrying valves and venous valve replacement devices, stents play a crucial role in providing structural support and placement assistance for these devices:

- Valve Delivery Systems: Stents are often utilized as a part of valve delivery systems for implanting heart valves or other types of valves within the body. These stents help in the proper positioning and deployment of the valve at the intended location. For example, in transcatheter aortic valve replacement (TAVR) procedures, a stent-based delivery system is used to implant an artificial valve within the native aortic valve.

- Venous Valve Replacement Devices: Venous valve replacement devices are designed to address conditions related to venous insufficiency, where the valves in the veins are weakened or damaged, leading to issues like chronic venous insufficiency or venous ulcers. Stents can be incorporated into these devices to aid in their deployment and fixation within the veins. These stents provide support to keep the replacement valve in place and functioning effectively.

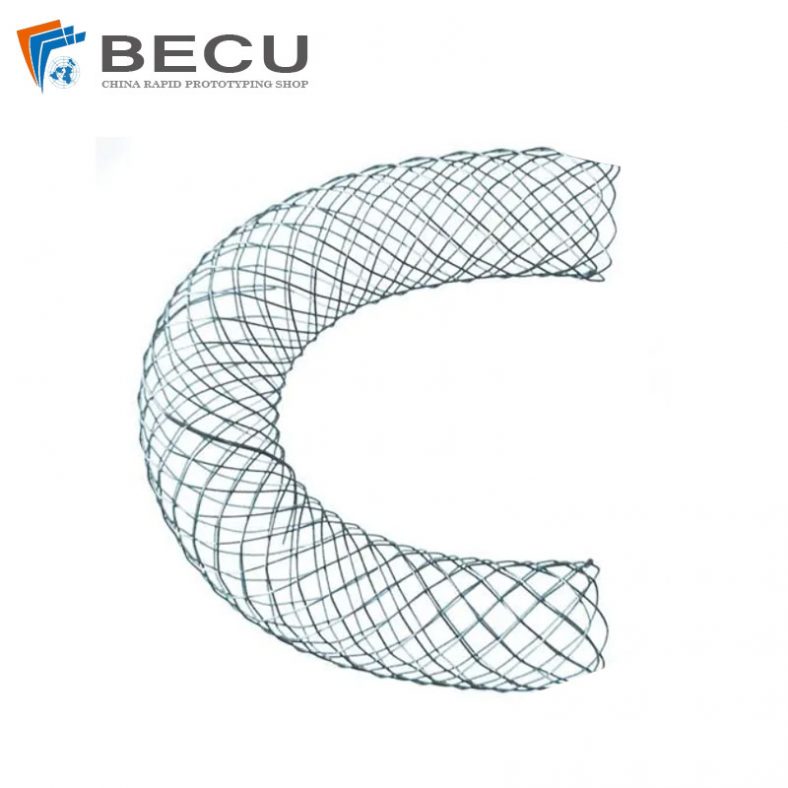

Stents used in these contexts are typically made of materials such as stainless steel, nitinol (a nickel-titanium alloy), or cobalt-chromium. They are often designed to be expandable, allowing them to be compressed for insertion into the body and then expanded to the desired size and shape once in position.

The development of stent technology continues to evolve, with ongoing improvements in design, materials, and deployment techniques aimed at enhancing their effectiveness, reducing complications, and improving patient outcomes in valve replacement and venous insufficiency treatment procedures.

Why Choose Our Cut Stents For Carrying Valves And Venous Valve Replacement Devices Service?

- we use advanced equipment to offer you Unparalleled precision for producing metal and plastic cutting parts

- We combine the latest laser cutting and sheet metal processes with proprietary technology to deliver high quality, on-demand parts

- Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

- We specialize in laser cutting, single part prototyping, short to medium production runs, manufacture parts on time, every time, so you can stay ahead of schedule

- We provide stainless steel laser cutting service, if you are looking for stainless steel parts cutting, then you are in the right place.

- Because of the cost problem, some designers change the ways to replace metal machined parts with plastic.

- Laser cutting plastic parts can create very similar parts to series parts. It is often more efficient and faster than other rapid prototyping technologies for the manufacture of a quantity of plastic prototypes between 1 and 10 parts . We also recommend plastic laser cutting for parts with large sizes (greater than 600 mm).

Contact Be Cu Now for your Custom Laser cutting, We are your best online Laser cutting services choice!

Specifications Of Cutting Stents For Carrying Valves And Venous Valve Replacement Devices

| Item Name | Micro Laser Cutting,Laser cutting service |

| Material | Aluminum,Carbon steel,Mild steel,Cold roll steel,Hot roll steel,Stainless steel,SECC,SGCC,SPCC,SPHC,Other metal |

| Thickness | 0.5mm-20mm,Depends on your products |

| High Precision | +/-0.001mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Powder coating,Nickel plating,Anodic oxidation,Chrome plating,Yellow zinc plated,Electroless nickel plating,Chemical conversion coating,Zinc plating,Electroplating,etc |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU Laser Cutting Company

BE-CU.COM Laser Cutting provides services to a wide network of industries and markets. BE-CU is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.We use large format industrial laser cutting machines that are extremely precise with up to .001” tolerance. Not only we cut and engrave your project, we are ready to answer any questions you may have about the process and give you expert advice.

So, reach out even if you’re unsure of your specific need or if you think you may require a different type of manufacturing service(as laser cutting medical parts). Laser cutting service by BE-CU makes ordering your parts simple. Just upload your CAD files onto the platform for an instant price and lead time. Our mission is to save engineers’ time for value-adding activities.

-

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

Laser Cut Nitinol Stent For Bile Duct

-

Stents For Carrying Valves And Venous Valve Replacement Devices

-

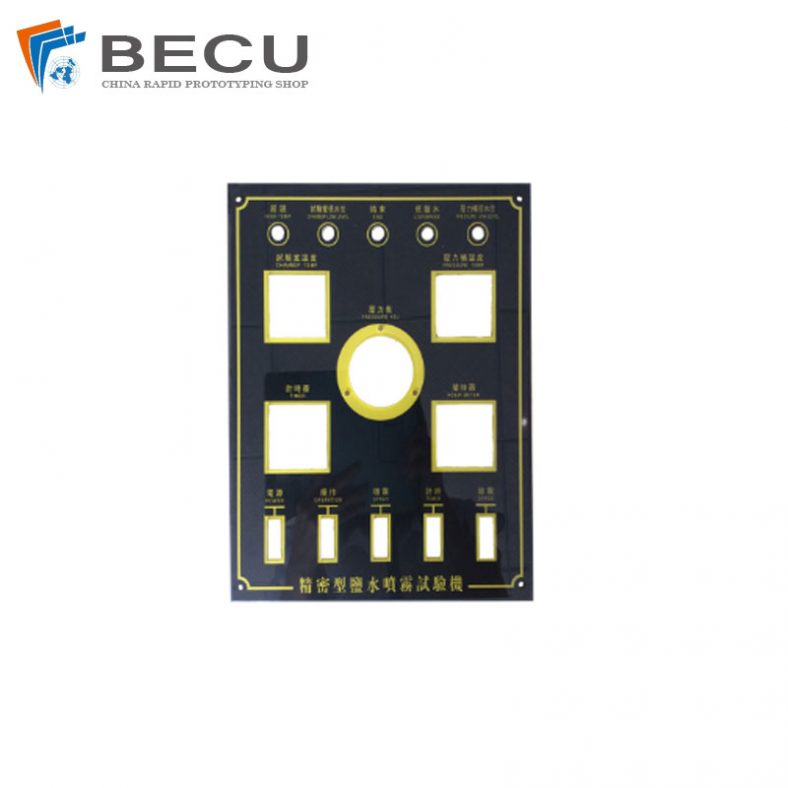

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

Acrylic Laser Cut Signs

-

Acrylic Laser Cut Earrings