3D Printing For Copper – What Is Copper 3D Printing

In the realm of manufacturing and fabrication technologies, the evolution of 3D printing has marked a revolutionary leap, expanding its horizons beyond plastics and polymers into the domain of metals. Among these metal constituents, copper, a versatile and indispensable element renowned for its conductivity and malleability, has emerged as a promising material in the arena of additive manufacturing.

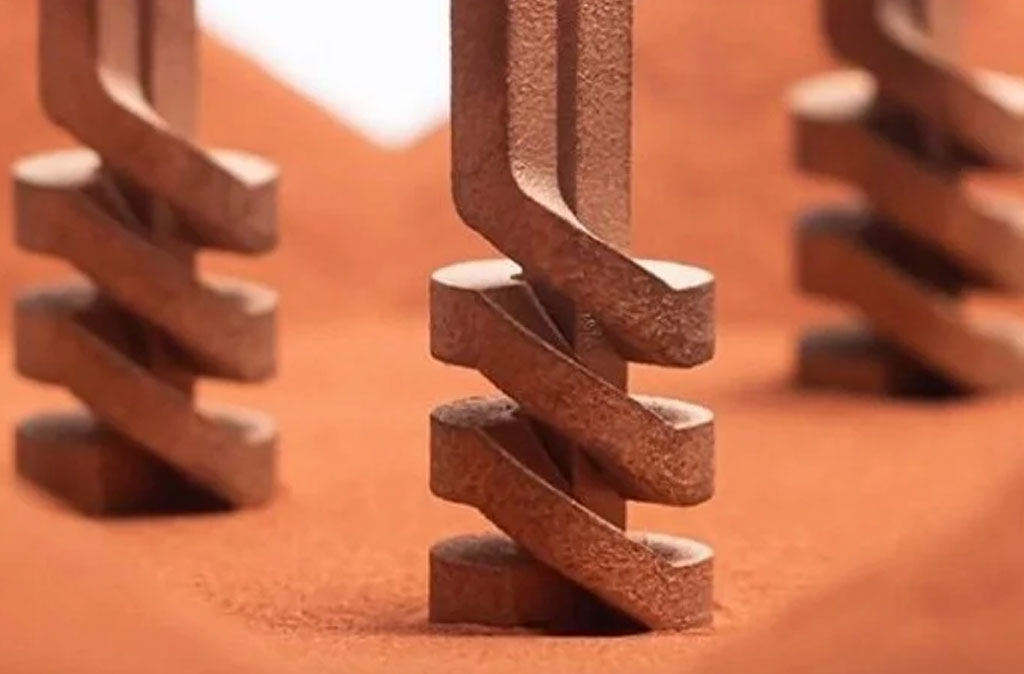

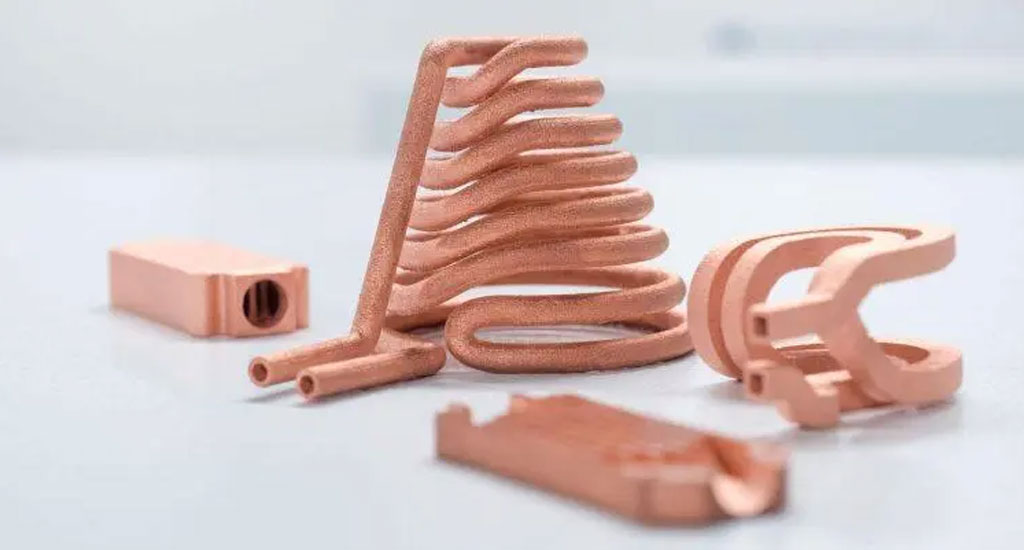

Copper 3D printing, also known as additive manufacturing or metal 3D printing, involves the use of copper-based materials to create three-dimensional objects layer by layer using a specialized 3D printing process.Copper 3D printing typically uses a technique called Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). In these processes, a high-powered laser is used to selectively melt and fuse layers of powdered copper or copper alloys based on a digital design or 3D model.

Copper 3D printing stands at the intersection of innovation and functionality, unlocking a realm of possibilities for industries seeking superior material properties, intricate designs, and tailored components.

As the pursuit of excellence in additive manufacturing continues, the role of copper in 3D printing is poised to leave an indelible mark, revolutionizing how we conceive, design, and fabricate intricate components with unparalleled precision and functionality.

Copper 3D Printing Services – 3D Printing Copper Parts

BE-CU Inc. is a leading service provider of copper 3d printing. With a vast industry experience and a large facility, we have the capability to meet your complex copper part 3d printing requirements. Since, our inception, we have served a huge variety of industries, including mold making,medical, military, marine, aerospace, and much more.

As a high-end Additive manufacturing shop,Be-Cu have more than 20 units of industrial copper 3d printers which can make your parts within 4 days.We control the cost in every process to help you save money on copper prints.Contact us and tell us what you need. We have been providing copper 3d printing service for almost 20 years. Our quote is completely free. And if you have any doubts about what technology will work best for you, our expertise is at your service.

Copper Grades We 3D Printing With

In 3D printing, particularly in metal additive manufacturing, copper-based alloys are commonly used due to their favorable thermal and electrical conductivity properties. Some of the copper grades utilized in 3D printing include:

Pure Copper (Cu-ETP)

Known as Electrolytic Tough Pitch Copper, it is a high-purity copper primarily used for its excellent electrical conductivity. It’s used in various electrical applications but can also be employed in 3D printing.

Copper Alloys:

- Copper Alloys with Additives (e.g., CuCr1Zr, CuNi2Si): These alloys incorporate other elements like chromium (Cr), nickel (Ni), silicon (Si), etc., to enhance specific properties such as strength, corrosion resistance, or hardness.

- Bronze and Brass Alloys: While not pure copper, these alloys contain varying proportions of copper along with tin (in bronze) or zinc (in brass). These alloys are sometimes used in 3D printing for their unique properties and aesthetics.

Copper-Based Powders for Additive Manufacturing:

Manufacturers often create specific copper-based powders designed explicitly for metal 3D printing processes like Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). These powders may have tailored compositions to optimize printability and material properties.

Each grade or alloy has its own characteristics and applications, catering to different industrial needs. The choice of a particular copper grade in 3D printing can depend on factors like mechanical properties required, thermal conductivity, corrosion resistance, and cost considerations.

Keep in mind that advancements in materials science and additive manufacturing techniques may introduce new variations or modifications to these copper-based materials for 3D printing.

Copper 3D Printing Capabilities

- Maximum Forming Printing Size Of Metal 3D Printer: 250x250x325mm;

- 3D printing layer thickness: 0.02mm~0.04mm;

- The Achievable Accuracy Of 3D Printing:Typical Accuracy: ±0.02-0.05 mm (Accuracy is related to geometry. It varies according to product size, printing direction, materials and post-processing methods.);

- Post-Processing: high temperature annealing, polishing, welding and other processing;

Certifications & Quality Printing

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Copper 3D Printing Parts & Case Studies

The metal 3D printer distributes even layers of metallic powder and the powdered metal is selectively melted to previous layers, which allows 3D metal parts to be fabricated of a bed of powdered metal. Using metal 3D printing allows us to produce parts with complex geometries that using traditional manufacturing methods not capable of and with materials that are difficult to process. 3D printing metal materials including aluminum, stainless steel, cobalt chrome, nickel alloy, titanium, etc.