What Is Multi Axis Cnc Machining

We are familiar with CNC Machining have three linear axes of XYZ, multi-axis refers to a machine tool with at least the fourth axis, three rotary axes for A, B, C.

Multi-axis CNC machining are usually referred to with three or more controllable axes (generally three linear axes plus one or more rotary axes), and these axes can be linked in the CNC system control of CNC machine tools. Common multi-axis CNC machines are mainly the following:

- 3 Axis CNC Machine

- 4 Axis CNC Machine

- 5 Axis CNC Machine

- Turning-Mill Machines

- Multi-Spindle Screw Machine

Multi-axis machining should be accurately said to be multi-axis machining, it is with the ordinary two-coordinate plane contour CNC Machining, point CNC Machining three coordinate surface CNC Machining is the essential difference is to increase the rotary motion, that is to say multi-axis machining tool axis relative to the workpiece is no longer fixed, but according to the needs of the tool axis angle is changing. The most widely used of these is the five-axis machining technology.

Application Of Multi-Axis CNC Machining

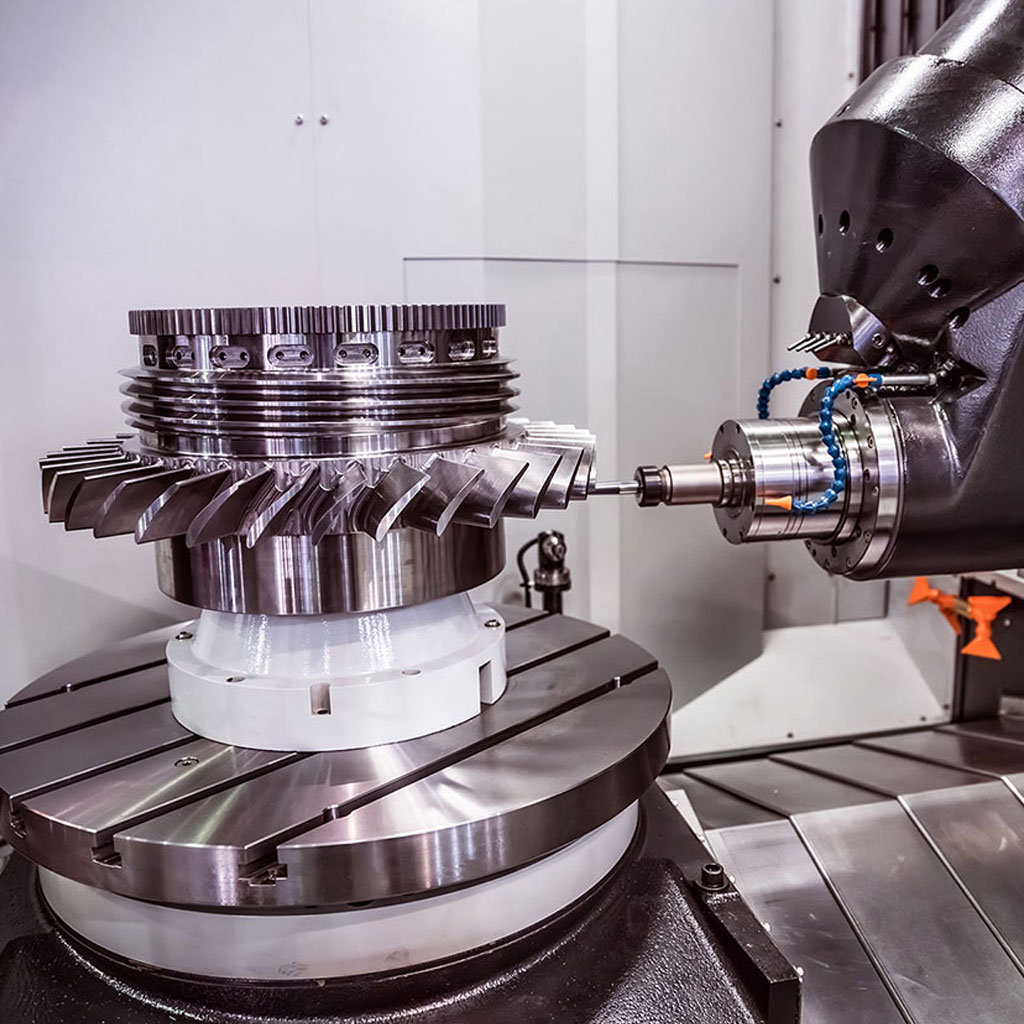

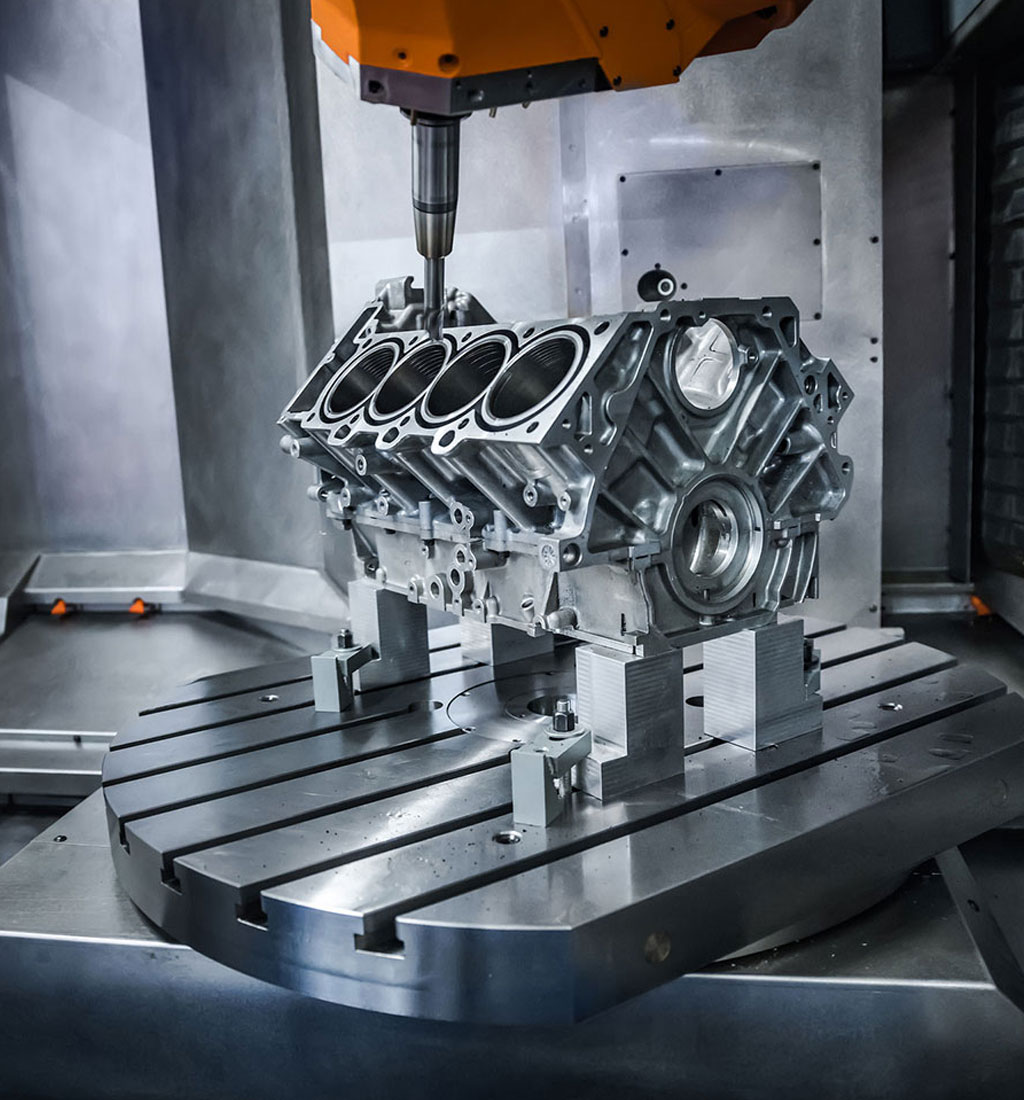

The Multi-Axis CNC Machining system is the only means of solving the processing of impellers, blades, marine propellers, heavy generator rotors, turbine rotors, large diesel engine crankshafts, etc.

In particular, the five-axis CNC machine system has a pivotal influence on a country’s aviation, aerospace, military, scientific research, precision instruments, highly sophisticated medical equipment and other industries.

The Characteristics Of Multi-Axis Machining

Compared to general CNC Machining, multi-Axis CNC Machining have the following main characteristics:

- Relative to the general CNC Machining, can be machined more complex workpiece.

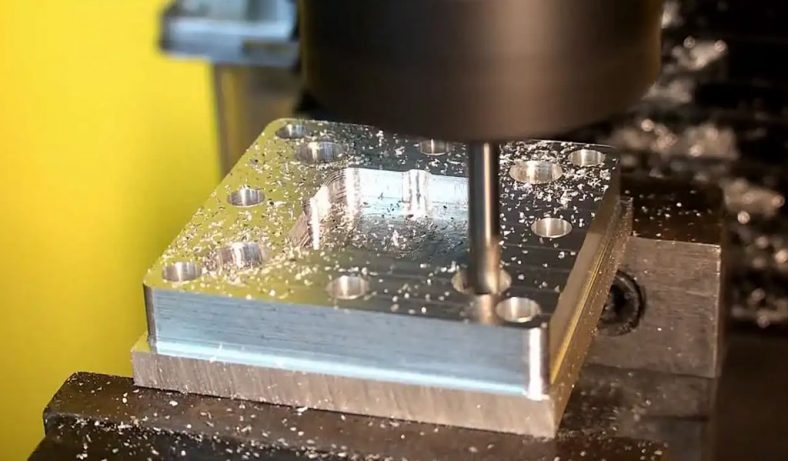

- can be completed in one clamping multi-faceted multi-directional cnc machining, effectively improve the efficiency and cnc machining accuracy.

- by changing the tool or workpiece attitude, effectively avoid tool interference problems, improve cutting efficiency and workpiece surface quality.

- The shape of the tool and fixture can be simplified to reduce machining costs.

Multi Axis Cnc Machining – Multi Axis Machining Services

Product Accuracy Is Our Attitude,We offer precision CNC turn-mill machining,3- 4 & 5-Axis CNC milling, CNC grinding and laser cutting services for precision parts. Meet your requirement on price and quality.Where We Build Your precision visions

At Precision CNC Machining of china, we pride ourselves in providing our customers with the highest quality and high value in every order.Be-cu.com(Pintejin Group) are here to assist you with all of your custom multi axis and custom multi-spindle needs and be-cu prototype assist you on your next project. We work closely with our customers to ensure that you are completely satisfied with your order and that your project is completed on time. We are manufacturer of 3/4/5 axis machining parts; we have DMU 5 axis CNC machines for our tooling system, with punching and plasma cutting available. It is our well-known level of service and our cutting edge technology that sets us apart from our competitors.

The Type Of Multi Axis Machining

Machining centres are generally divided into vertical machining centres and horizontal machining centres. The most effective machining surface of the three-axis vertical machining centre is only the top surface of the workpiece, and the horizontal machining centre can only complete the machining of four sides of the workpiece with the help of a rotary table.

Multi-axis CNC machining centres are characterised by high efficiency and precision, and the workpiece can be machined on five sides after a single clamping. If the configuration of 5-axis linkage of high-grade CNC system, but also on the complex space surface for high-precision cnc machining, very suitable for processing automotive parts, aircraft structural parts and other workpiece moulds. According to the form of rotary axis, multi-axis CNC machining centres can be divided into two types of setup

- Table rotary axis: the advantages of this way of setting up multi-axis CNC machining machine tools are: spindle structure is relatively simple, spindle rigidity is very good, manufacturing costs are relatively low. However, the general table can not be designed too large, the load is also small, especially when the A-axis rotation angle ≥ 90 °, the workpiece cutting will bring a large bearing moment on the table.

- Vertical spindle head rotation: The advantage of this set-up of multi-axis CNC machining machines is that the spindle processing is very flexible and the table can be designed to be very large. In the use of spherical milling cutter processing surface, when the tool centre line is perpendicular to the processing surface, due to the vertex of the spherical milling cutter line speed is zero, the vertex cut out of the workpiece surface quality will be very poor, and the use of spindle rotation design, so that the spindle relative to the workpiece turned at an angle, so that the spherical milling cutter to avoid vertex cutting, to ensure that there is a certain line speed, can improve the quality of surface machining, which is difficult to do table rotary machining centre This can improve the quality of the surface finish, which is difficult to achieve with table rotary machining centres.

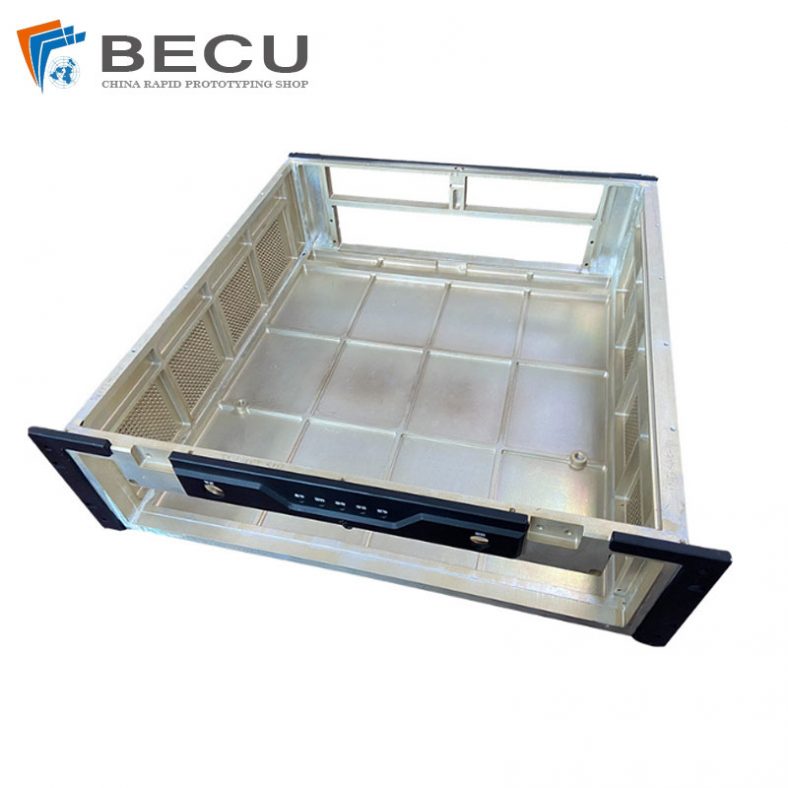

Be-cu.com offers an added advantage of precision machining,Multi Axis Cnc Machining, and milling for quality-oriented customers in highly competitive markets. From milling plate stock to machining elaborate enclosures, we guarantee the highest degree of accuracy for a wide array of industries and products at competitive prices with quick lead times.

Our Case Studies Gallery Of Multi Axis Cnc Machining Parts

We are in the business of creating products that save you time and money. In addition to our Multi Axis Cnc Machining services, we provide laser cutting, sheet metal manufacturing, die casting, and 3d printing. All customers’ orders are inspected by our team to ensure they ship complete with hardware, finish, silk-screening, electronic component assembly, and testing.

Don’t see what you are looking for? Reach out to us and learn how we can work together to create what you need.

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

Precision Machining 6063 Aluminum Military Computer Server Chassis