Custom Aluminum Extrusion Profile Company – Best China Aluminum Extrusion Service

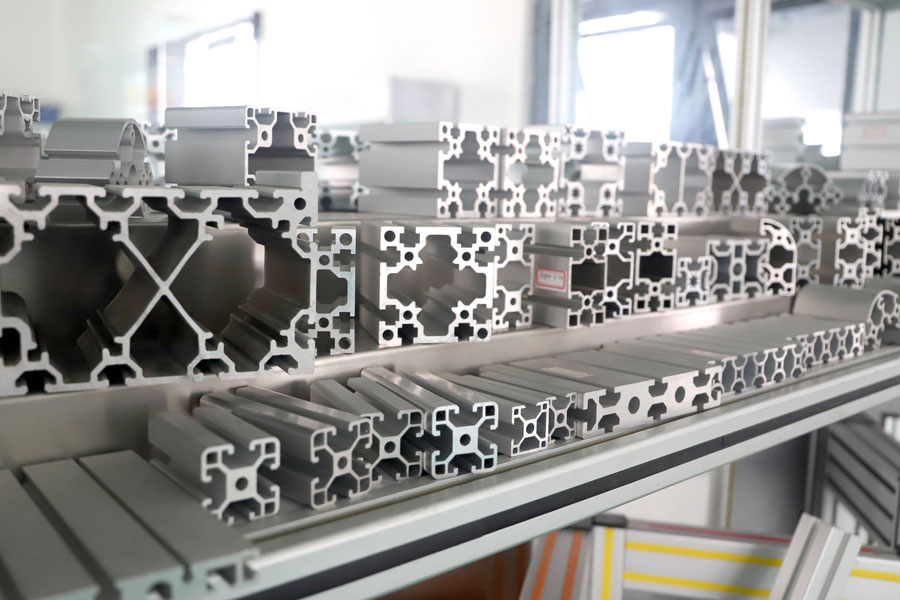

Welcome to BE-CU prototype company, a leading aluminum extrusion profile company located in Dongguan city of China, We specialize in creating high-quality aluminum extrusion for a wide range of industries, including automotive, electronics, medical devices, and ship products to America, Europe, and the world.Whether your project needs are for a few hundred of parts in a short period or millions of parts over a long period, we’ll have the right custom simple or complex shapes can be handled solution to save the cost for you

Once you selected us, our engineers will start with understanding your demands, select the aluminum extrusion design suits the application, figure out the aluminum extrusion shapes, dimensions, specifications, tolerances, and all of the details before production, we work together at every step all the way,The aluminum extruder is setup with dies and ancillary equipment, producing almost any shape imaginable is possible with suitable extrusion dies, in the design and function testing until the end of the project, we will review all of the possible potential issues and bring all of the suggestion to you.

After the first sample parts coming out, our expert team will send you samples and review the parts, and we will re-sample for you from time to time until you have the perfect goods in surface, function, assembly, etc. until completely achieve your goal, your will find out we are the best Extrusion Profile company that to support your business.

Our experienced team of designers and engineers has been working in the aluminum extrusion profile and cnc machining industry for over 30 years, providing innovative solutions to our clients around the world. With our advanced technology and state-of-the-art equipment, we are able to produce molds that are precise, durable, and cost-effective.

At our aluminum extrusion profiles company, we are committed to providing our clients with exceptional service from start to finish.Our aluminum extrusion profiles are commonly used in the consumer electronics and construction industry, such as frames of doors and windows, also serve for automotive, trains, ships, medical devices, etc. Multiple types of aluminum alloys are available for the manufacturing of aluminum extrusion profiles, such as 6061, 6063, 7075, etc.We understand that every project is unique, which is why we take the time to listen to our clients’ needs and work closely with them throughout the design and production process.

Aluminum Extrusion Dies & Tooling

Aluminum extrusion dies play a crucial role in determining the shape, quality, and precision of the extruded profiles. Extrusion dies can be made to form a virtually limitless array of profile shapes and sizes. You may be most familiar with standard shapes such as angles, channels, and tubes — all of which are commonly available from extruders and distributors.Aluminum extrusion dies and tooling play a critical role in the extrusion process, shaping the molten aluminum into specific cross-sectional profiles.As a professional dies & tooling factory in china, We specialize in the production of aluminum extrusion dies & tooling for a wide range of industries and applications.

We bought some high tech equipment to make the high-quality aluminum extrusion dies & tooling to all of our customers, with our professional mold designers, mold makers, tooling engineers, project managers, and professional english communication, we can make the best quality of aluminum extrusion dies & tooling and aluminum molded products, as we all know better mold to make better molding parts. We offering various types of dies used in aluminum extrusion, including solid dies, hollow dies, and common dies:

- Solid Die: A solid die is a die that forms a continuous, solid cross-sectional shape of the extruded aluminum profile. It is used for creating solid shapes like rods, bars, or simple profiles without any internal voids.

- Hollow Die: A hollow die, also known as a porthole die, is used to produce aluminum profiles with internal voids or hollow sections. These hollow sections can be various shapes such as square, rectangular, circular, or complex profiles like tubes or channels. Hollow dies have a mandrel or pin inside that helps in shaping the internal features of the extrusion.

- Common Dies: Common dies refer to dies that are commonly used in aluminum extrusion processes. These can include dies designed for standard shapes or profiles that are frequently used in different industries. They might encompass a range of solid and hollow dies based on industry demands and standard shapes required for various applications.

Each die type serves specific purposes, and their design is based on the desired profile, shape complexity, and internal features required in the extruded aluminum product.

Die and tooling design are crucial aspects in aluminum extrusion, impacting the quality, accuracy, and efficiency of the process. Precision engineering of dies and tooling is necessary to ensure consistent and reliable production of aluminum profiles with the desired dimensions and properties.

Aluminum Extrusion Profile Capabilities

Be-Cu prototype company custom and OEM aluminum products that range from basic mill finished extrusions all the way to finished, fabricated shapes. With in-house value added services such as anodizing, painting, thermal improvement, fabrication and specialized packaging, we ensure consistent quality products delivered on time.Typical capabilities used for custom aluminum extrusions include:

| Maximum Extrusion Sizes | Up to 18 inch circles |

| Maximum Ram Pressure | 550 tons |

| Maximum Extrusion Profile Diameter | Ø 4.5 in. |

| Tolerances | ± 0.005 in. Typical Can Achieve ± 0.002 in. on Special Profile Features |

| Additional Services | – Fabricating – Anodizing – Painting – CNC machining – Assembly – Stamping – Bending – Grinding – Conditioning |

| Extrusion Forms | – Hollow Shapes – Profiles – Rod/Bar – Rods – Semi-Hollow Shapes – Solids – Tubing |

| Alloys Extruded | We work with the following materials in a variety of tempers and finishes: – 6005 – 6105 – 6061 – 6063 – 6493 – 7075 |

| Production Volumes | We require a minimum order of 1000 lbs. per shape. |

below we have a more valuable suggestion for you to make a decision based on your production and quality needs. The more you know, the better your choices will be. If you want to know more suggestions from our team, please contact our technical team, we will offer you the best solutions to reduce the cost to your project and make your project going fast, smoothly and successfully.

We are proud of our reputation gained around two decades supplying high-quality Aluminum Extrusion and molds to customers in major industrial nations. So far, our reputation as being an on-time reliable, quality and cost-effective supplier has been growing.Are you ready to start your new project now? Contact our team and let us be your partner all the way together, you will be 100% happy with BE-CU aluminum extrusion company.

Applications of Custom Aluminum Extrusions

Custom aluminum extrusions are used in a wide variety of industries. Some typical applications are listed below:

Construction and Architecture

Transportation

Electronics and Electrical Industries

Consumer Goods

Industrial Applications

Renewable Energy

Medical Equipment

Lighting and Signage

By partnering with us for your aluminum extrusion needs, you receive quality parts at lower costs in shorter time periods.

Why Choose Our Aluminum Extrusion Service?

- Save time and money for your aluminum Extrusion project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of aluminum grades and alloy materials can be extrusion

- Custom complex aluminum extrusion parts and components at specific tolerances

- High speed extrusion for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Aluminum Extrusion Parts & Case Studies

If you want to have an estimated price for initial market evaluation, you are welcome to send us your 3D data (STP or IGS format), you don’t have any lost but have our competitive price for a reference.

We never share your data with any other third parties, we are willing to sign the Non-Disclosure Agreement (NDA) document to protect your project.

We could save you up to 40% Initial mold investment cost, if we produce the aluminum extrusion parts for you we will never earn any piny of profits in mould making or even put 30% of tooling costing for your project (depending on the requirement of volume on your project).

If you have a technical question, you are welcome to contact our technical manager by email [email protected], who speaks fluent English and has over 15-year technical working experience, will help to solve any of your technical issues and save cost for you

If you work with us. You will be impressed and fully satisfied with our quality, price, service, and fast lead time.

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

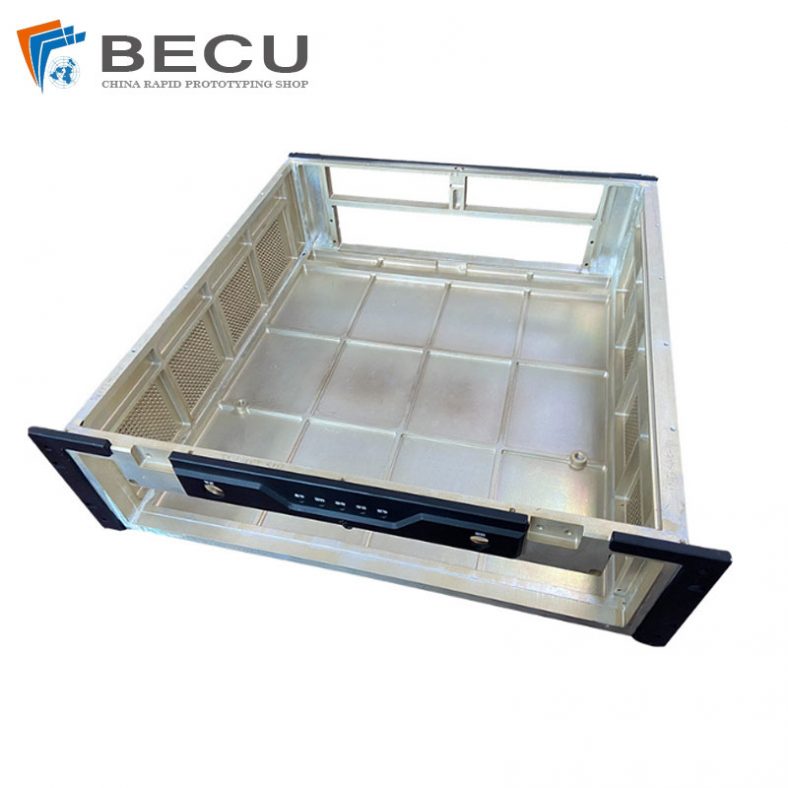

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

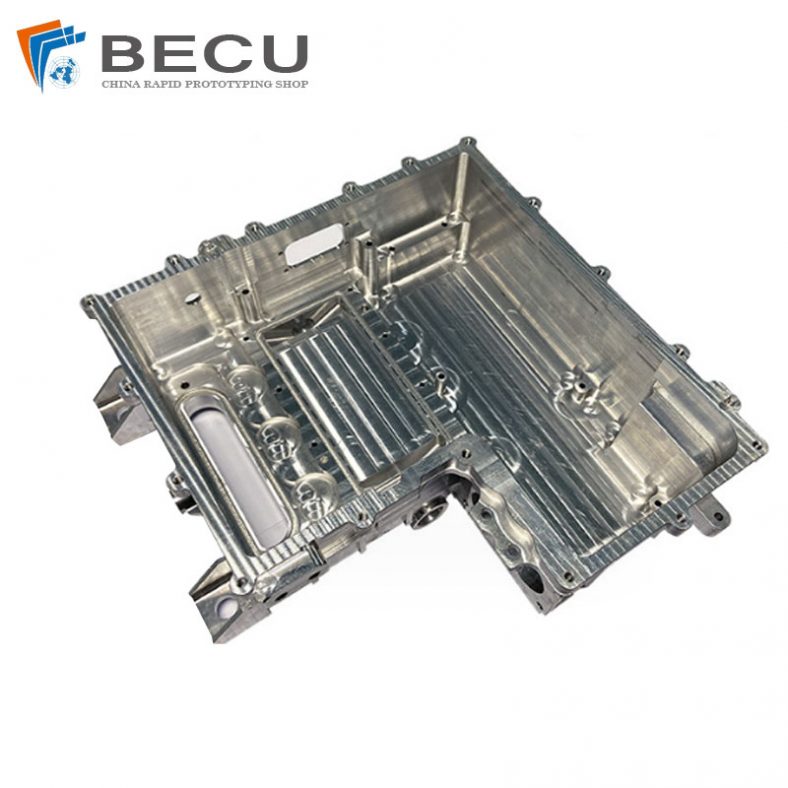

CNC 6063 Aluminum Automotive Motor End Cover

-

CNC Machining Gas Stove Bottom Joint

-

CNC Turning 6063 Bicycle Tightening Disc

-

Precision CNC Machining Unmanned Aerial Vehicle Motor Base

-

Metal CNC Machining Motor Front And Rear Covers

-

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining

-

CNC Machining For Camera L Bracket

-

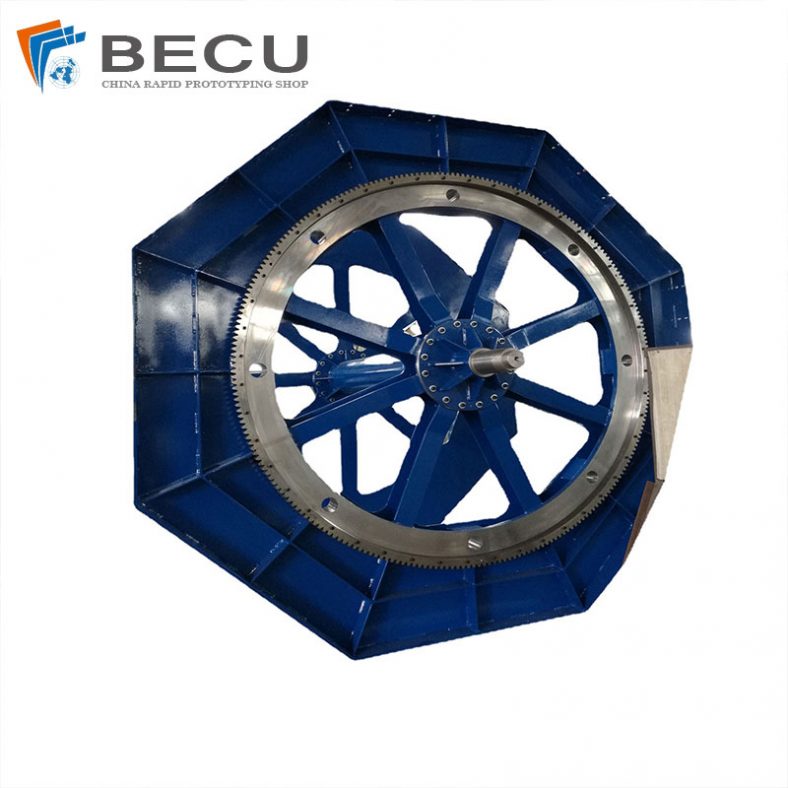

Welding CNC Machining 5M Drum For Centrifugal Fan

-

Large Machining Micro-Automation Robots Joint

-

CNC Machining 6061-T1 Electromagnetic Clutch Parts

-

Precision Machining 6061-T1 Automobile Motor Prototype

-

Precision Machining Security Door Lock Guard Housing

-

Custom Electron Optical Instrument Sight Bracket