Precision Welding Service | Welding Supplier

Be-cu Prototype is a full-service machine shop specializing in a wide range of metal fabrication services, including welding. Our welders have extensive experience in Metal Inert Gas (MIG) and Tungsten Inert Gas (TIG) arc welding.Welding services by china welding supplier help you to complete your projects on time, whether prototype or serial welding.

As an ISO 9001:2015-certified business, quality assurance is central to our business philosophy.With more than 3,000 square feet of combined space, our welding facilities in Dongguan, and huizhou, are outfitted with the latest technology and equipment to pre-fabricate systems and confirm proof of concept, which help reduce field welding time and deliver first-time quality.

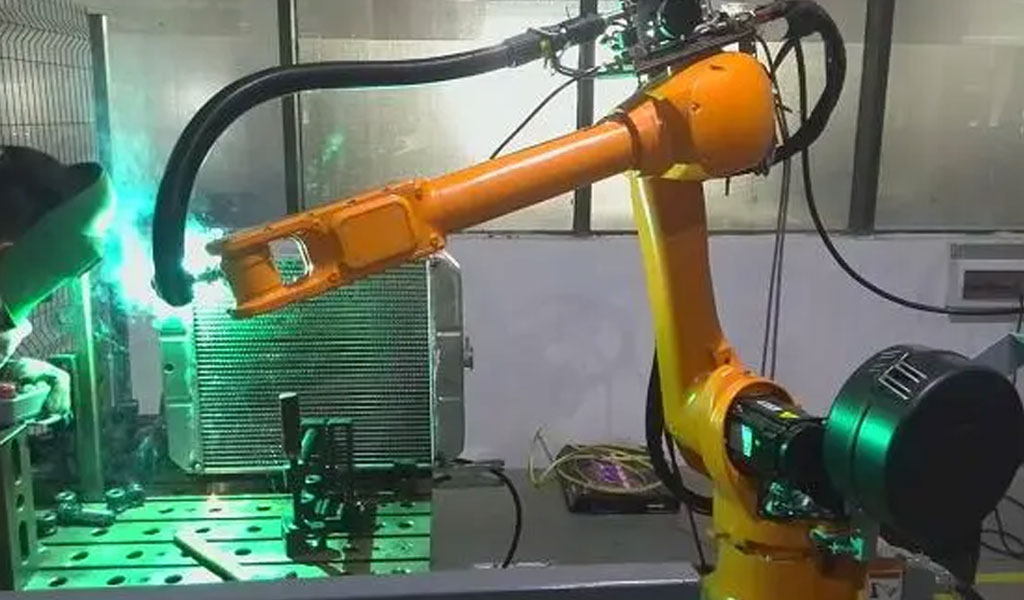

We are proud to serve the automotive industry, powersports industry, construction industry and beyond, using the newest robotic welding equipment and manual welding techniques to produce frames, suspensions, winterization for vehicles and more.We can even install iron products of any size or dimensions. Conveyors, stairs, railing, building components, wrought iron fencing ect. Welding steel, Aluminum, and stainless is what we do.

Be-cu prototype has years of experience in welding and metal fabrication. Our welders work with a variety of mediums using the latest in welding techniques and equipment. We look forward to working with you on your custom fabrication design. To see how our welding capabilities can support your needs, please request a quote or contact us today.

Precision Welding Capabilities

As one of the top international welding companies, we are proud to provide our clients with a number of welding services, including robotic welding for resistance spot welding and arc welding in high-production applications, mechanical welding for welding areas that machines cannot reach, TIG welding for thinner metals and MIG welding for thicker metals.

TIG Welding

MIG Welding

Robot Welding

Sheet Metal Welding Service

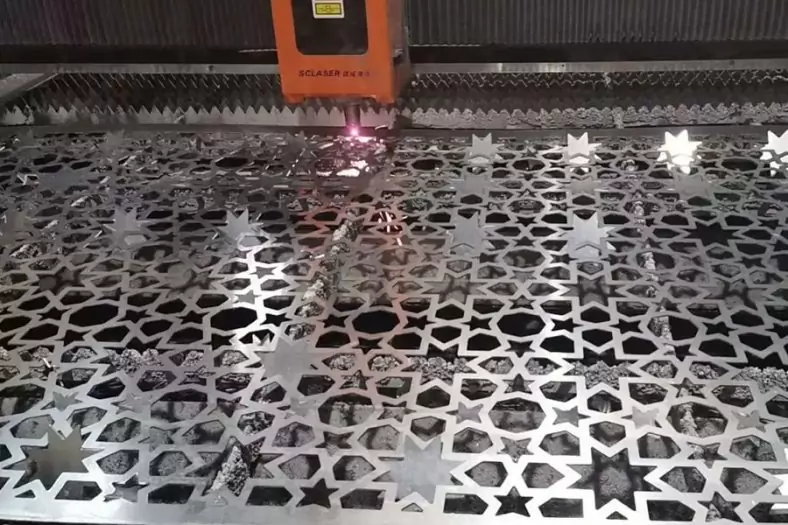

Are you in need of top-notch welding operations for custom sheet metal fabrication? Or you don’t know how to weld sheet metal for your manufacturing needs? Be-cu.com is just what you need. We offers a range of sheet metal materials, including aluminum, copper, steel, and stainless steel, as well as assembly services like welding, and finishing services. Be-cu offers competitive, custom sheet metal welding and fabricating prices for low volume prototypes and cost savings for high volume production runs.

Be-cu.com provides outstanding and professional sheet metal services. We just require you to upload your design files. You get a free DfM analysis report on the manufacturing of your sheet metal parts. What’s more? We guarantee high quality at competitive pricing and fast lead times.

Precision Welding Process

There are five basic steps to precision welding, no matter your welding process.Below is a stepwise procedure on how we generally function:

- First, we prepare the aluminum or stainless steel tubes by cutting, smoothing edges, punching holes or stamping based on the client’s specifications.

- The metal tube then goes to the robot welding line. Of the many welding processes, robotic welding is highly accurate, enhances safety and reduces production time.

- Once the component is complete, it goes to quality inspection where 5 out of 100 parts are tested. If one problem is found, the whole batch is inspected to ensure they meet the required tolerance.

- Molten metal is highly malleable. Some aluminum frames require heat treatment due to deformation that occurs when the welding device creates excessive heat.

- The components are shipped to an assembly plant. We deliver automotive and powersports frames fully painted and coated, with the quality of having a mirror effect.

As a rule of thumb, welders should measure twice and cut once. In some cases, you may need to redesign joints to have higher heat resistance.

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- ITAF 16949 certified

Fabrication And Welding Materials

Be-cu.com’s welding service only focuses on one group of materials – different types of metal. Therefore, we include a list of most common metals with their maximum recommended thickness for getting the best quality results:

- Mild steel – up to 30 mm

- Stainless steel – up to 30 mm

- Special steels (Hardox, Strenx, etc.) – up to 20 mm

- Coated steel – up to 5 mm

- Aluminium – up to 30 mm

- Copper alloys – up to 12 mm

If you have any questions, you can check our welding quote page for more information or turn to our engineers via email.

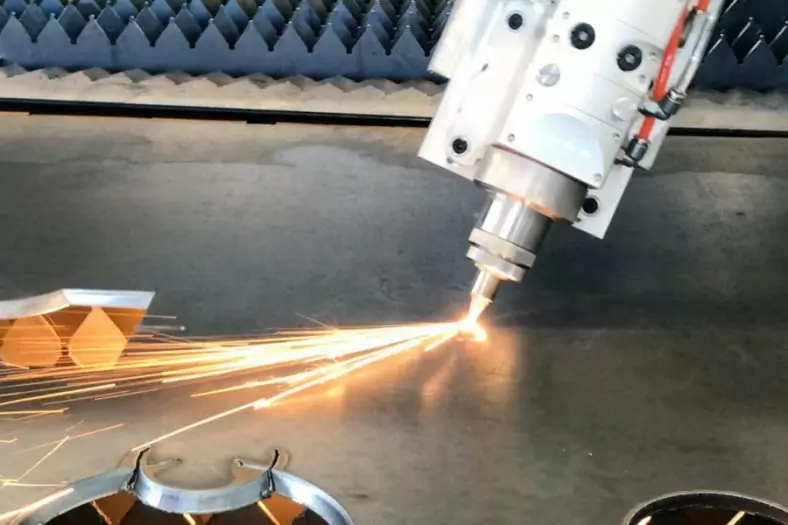

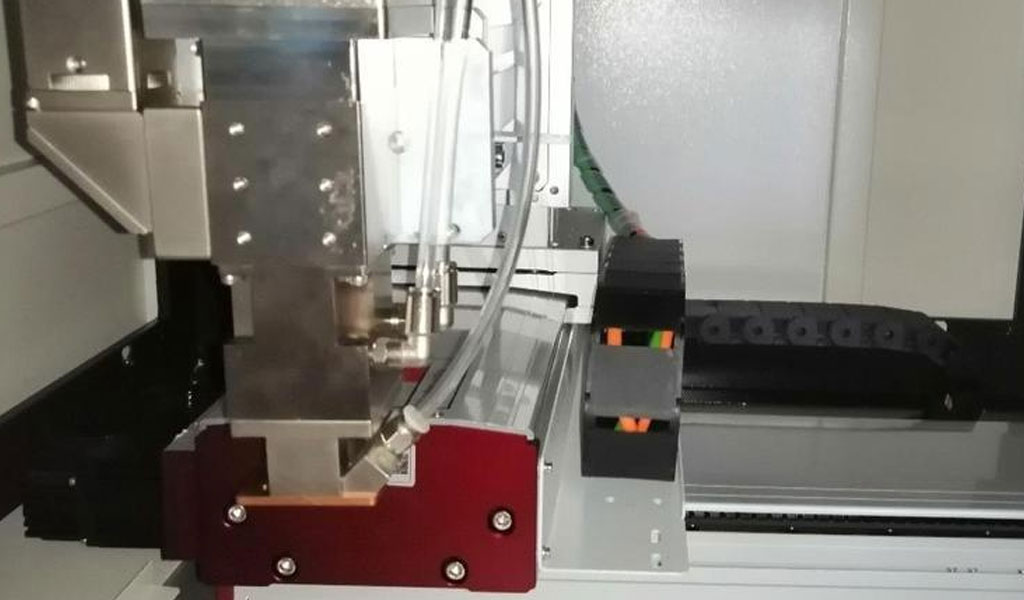

Our Outstanding Welding Equipment

- 4-Axis/6-Axis Automatic Laser Welder

- 6 Axis Robotic Arm Welder

- Handheld Laser Welder

- TIG200 Argon Arc Straight Seam Welder

- VEVOR MIG-270 Welder

- Arc Type MIG 350 Welder

- 110-220V Handheld Welding Machine

- Pedal Spot Welding Machine

- Check Out BE-CU Equipment List

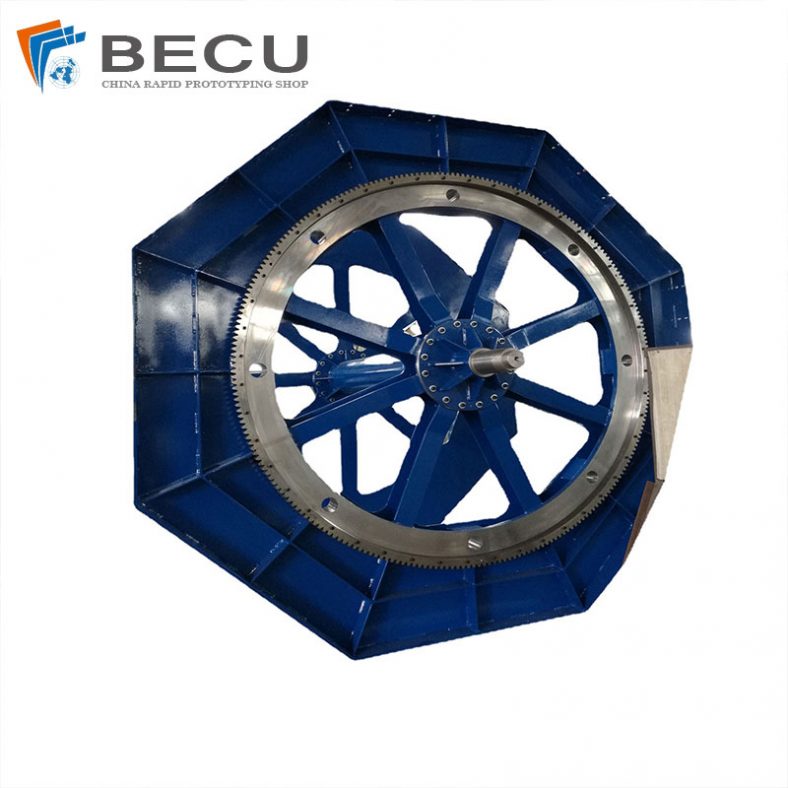

The Case Studies Of Fabrication And Welding Parts

You have a complex part design, Our welding service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Precision Fabrication Green Energy EV Charging Station Cabinet

-

Outdoor Rainproof Weak Current Communication Network Sheet Metal Cabinet

-

Welding CNC Machining 5M Drum For Centrifugal Fan

-

Sheet Metal Fabrication Large BBQ Grill Enclosure

-

Sheet Metal Fabrication For Large Japan Mill Machine Enclosure

-

Sheet Metal Fabrication Distribution Electric Cabinet

-

Sheet Metal 32 Inch LCD Industrial Bracket

-

Metal Fabrication Cold Rolled Sheet Medical Device Enclosure

-

Sheet Metal Manufacturing 10.1 Inch Hardware Monitor Enclosure

-

32-Inch Medical Sheet Metal All-In-One Machine Cabinet

-

Precision Fabrication Wall Mount Gaming Computer Case Chassis

-

0.8MM All Aluminum Sheet Metal Mini Host Computer Chassis

-

12.1 Inch Vertical Inquiry Kiosks

-

65-Inch Vertical Touch All-in-one Advertising Machine Sheet Metal Shell

-

LCD Display Advertising Machine Sheet Metal Frame

-

Custom 32 Inch Ordering Machine Kiosk Chassis

What Is Welding Process

Welding is a process of joining two or more pieces of metal or thermoplastics together by applying heat, pressure, or both. The welding process involves the localized melting and fusion of the materials to form a strong bond. It is widely used in various industries, including manufacturing, construction, automotive, aerospace, and more.Welding plays a crucial role in numerous industries, contributing to the construction of infrastructure, manufacturing of machinery and equipment, and the production of consumer goods.

How Does Welding Work?

Welding works by joining two or more pieces of metal or thermoplastics together through the application of heat, pressure, or both. The welding process involves several key steps:

Different Types of Welding and Their Uses

There are several different types of welding processes, each with its own characteristics and applications. Here are some common types of welding and their uses:

Shielded Metal Arc Welding (SMAW)

Also known as Stick welding, SMAW involves using a consumable electrode covered in flux. It is a versatile welding method and is widely used in construction, maintenance, and repair work, as well as in pipelines and structural steel fabrication.

Gas Metal Arc Welding (GMAW) or Metal Inert Gas (MIG) Welding

GMAW uses a consumable wire electrode and a shielding gas, typically a mixture of argon and carbon dioxide. It is commonly used in manufacturing, automotive, and fabrication industries for welding thin to medium-thickness materials.

Flux-Cored Arc Welding (FCAW)

FCAW is similar to GMAW, but it uses a tubular wire electrode filled with flux instead of a solid wire. It is known for its high deposition rates and is often used in heavy fabrication, shipbuilding, and structural steel applications.

Gas Tungsten Arc Welding (GTAW) or Tungsten Inert Gas (TIG) Welding

GTAW uses a non-consumable tungsten electrode and an inert gas, such as argon, for shielding. It is known for its high-quality welds and precise control, making it suitable for aerospace, automotive, and nuclear industries, as well as for welding thin materials and exotic metals.

Submerged Arc Welding (SAW)

SAW involves feeding a continuous wire electrode into the joint while covering it with a granular flux. It is primarily used for welding thick materials in heavy fabrication, pressure vessel manufacturing, and pipe welding applications.

Resistance Spot Welding (RSW)

RSW uses electrodes to clamp and apply pressure to the joint area, passing an electric current through it. It is commonly used in the automotive industry for joining sheet metal components, such as body panels.

Electron Beam Welding (EBW)

EBW utilizes a highly focused beam of electrons to generate heat and create welds. It is used for joining high-strength materials, critical aerospace components, and precision welding applications.

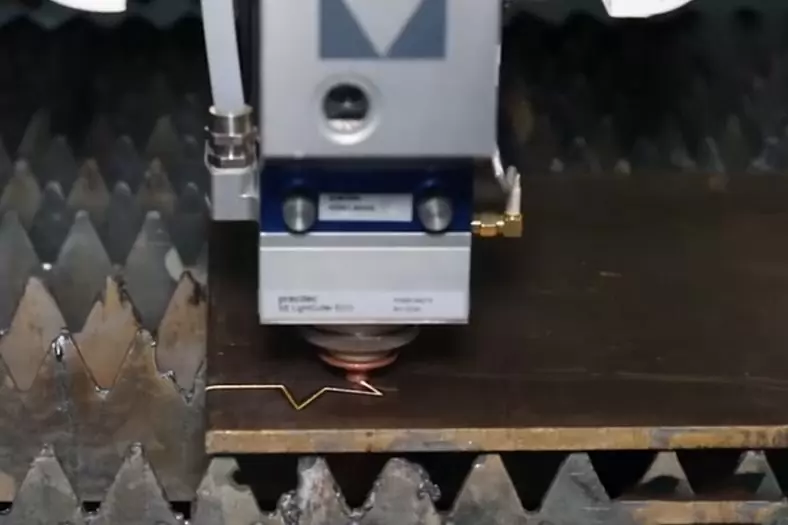

Laser Beam Welding (LBW)

LBW uses a highly concentrated laser beam to generate heat and create welds. It is suitable for precision welding of thin materials, medical devices, electronics, and automotive components.

Friction Stir Welding (FSW)

FSW involves using a rotating tool to create friction and heat, joining materials without fully melting them. It is used for joining aluminum and other non-ferrous materials, particularly in the aerospace and automotive industries.

Online Cooperate With China Precision Welding Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision welding capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.