3D Printing For Nickel – What Is Nickel 3D Printing

Nickel 3D printing, a groundbreaking additive manufacturing technique, has emerged as a transformative process in the realm of industrial production. Leveraging the versatility and unique properties of nickel, this innovative method has opened new avenues across various sectors, including aerospace, automotive, electronics, and healthcare.

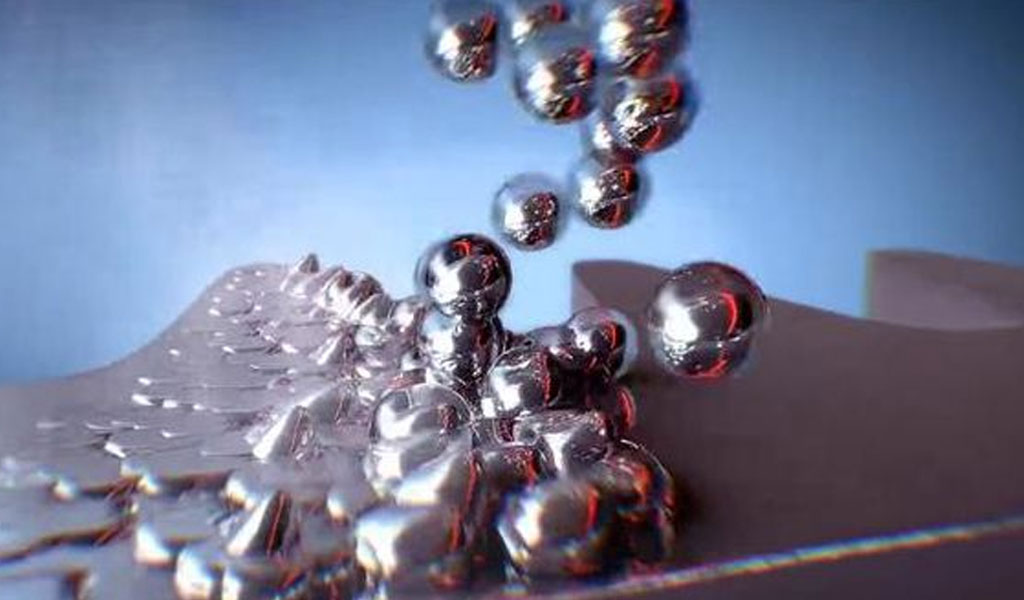

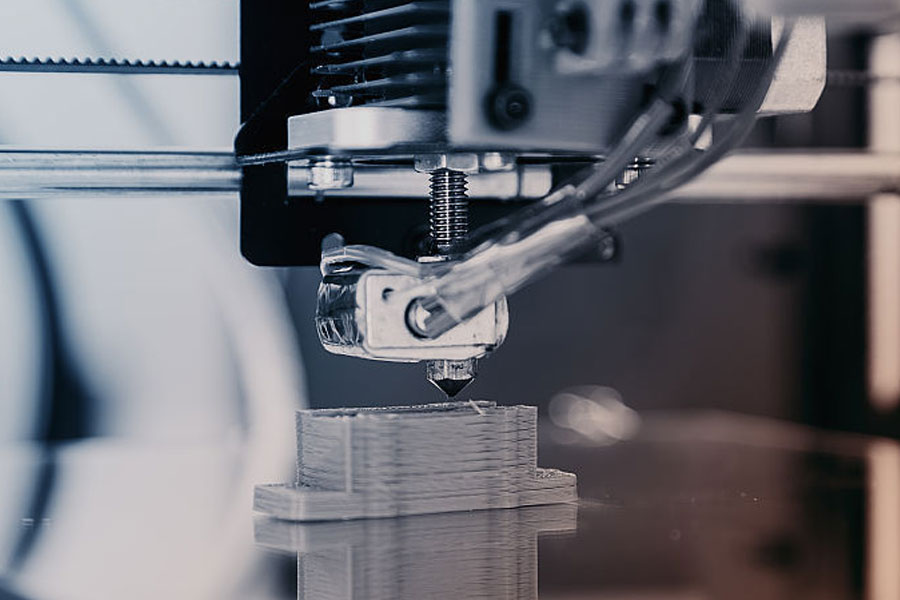

At its core, nickel 3D printing, also known as direct metal laser sintering (DMLS) or selective laser melting (SLM), utilizes powdered nickel alloys as the raw material. The process begins with a digital model sliced into layers, which is then fed into a high-powered laser system. This laser selectively fuses or melts the powdered nickel in precise patterns, layer by layer, conforming to the design specifications dictated by the digital model.

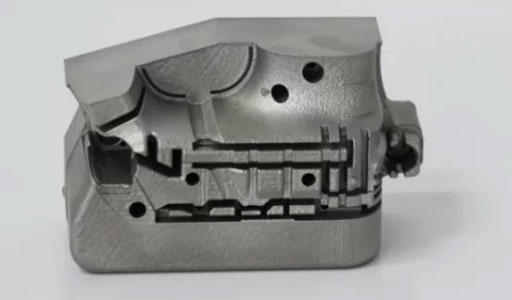

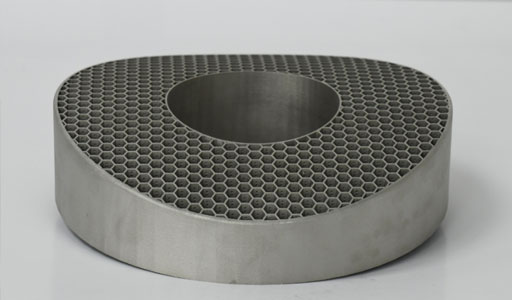

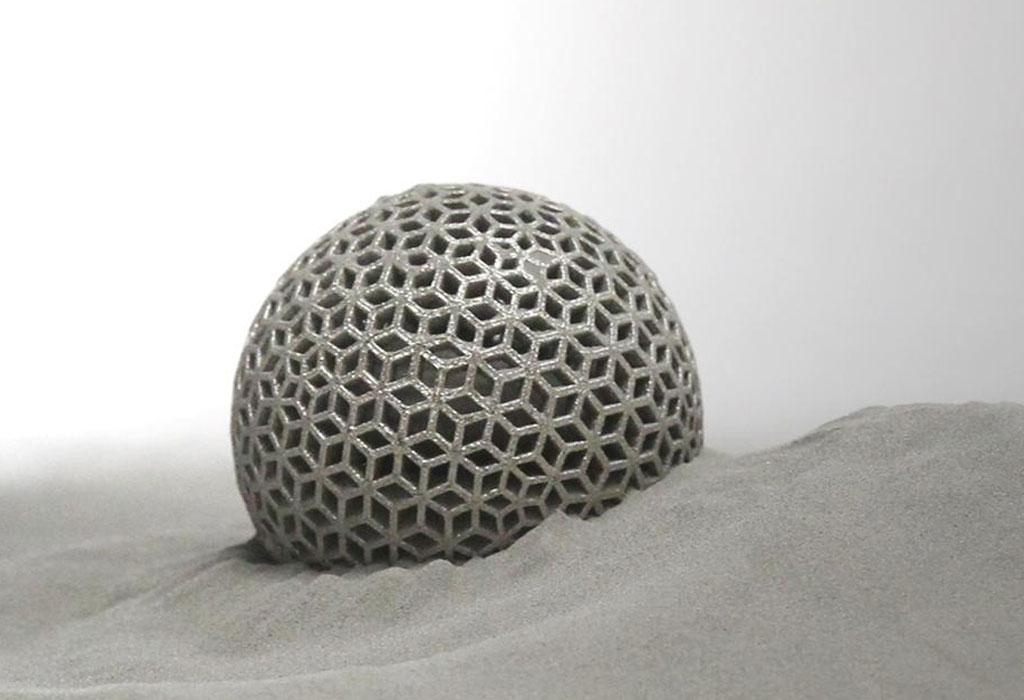

Through this additive approach, intricate and complex structures can be formed with exceptional precision and detail, surpassing the limitations of traditional manufacturing methods.

One of the primary reasons for the growing interest in nickel 3D printing is the exceptional mechanical properties of nickel alloys. Nickel exhibits outstanding strength, corrosion resistance, high-temperature stability, and excellent conductivity, making it an ideal choice for a wide array of applications. Moreover, the ability to fine-tune the composition of nickel alloys during printing allows for the creation of materials tailored to specific requirements, enhancing their performance characteristics further.

Nickel 3D Printing Service – 3D Printing Nickel-Based Alloy

BE-CU is equipped with a history of Nickel 3D printing experience, During the nickel additive manufacturing process, a laser beam melts 20-60 micron layers of powdered nickel, making a part from a bed of powdered metal,as well as qualified operators, engaged project managers, and logistics that keep our customers at the forefront of our operations.

We are prepared to support all your direct metal printing production. Our selective laser melting (SLM) machine can print complex geometries with ease.By utilising the endless opportunities of our metal powders, we know that we can lead a wave of change for the better. With people at every level of our organisation dedicated to redefining what is possible, we continue to amaze the world with new breakthroughs.

Which Nickel Grade for 3D Printing

When it comes to nickel alloys used in 3D printing, several grades offer specific properties and characteristics suited for various applications across industries. The selection of the appropriate nickel grade depends on the intended use, considering factors such as mechanical strength, corrosion resistance, thermal conductivity, and other specific requirements.Here are some common nickel alloy grades utilized in 3D printing:

Inconel Alloys (e.g., Inconel 625, Inconel 718)

Hastelloy Alloys (e.g., Hastelloy X, Hastelloy C-276)

Rene Alloys (e.g., Rene 80, Rene 125)

Maraging Steel

GH4169 3D Printing

GH4169, also known as Inconel 718, is a nickel-based superalloy that is widely used in various high-performance applications, especially in aerospace, automotive, and industrial sectors. Its exceptional mechanical properties, corrosion resistance, and ability to withstand high temperatures make it a popular choice for 3D printing applications.

Utilizing GH4169 for 3D printing involves a process known as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). These additive manufacturing techniques involve melting and solidifying powdered metal layer by layer, based on a digital design model.

Several performance make GH4169 an attractive material for 3D printing:

| Project | Project | Performance | Performance | Testing Standards |

|---|---|---|---|---|

| Print Parameters | Layer Thickness (μm) | 45 | / | / |

| Physical Properties | Density(g/cm3) | ≥8.15 | / | GB/T 3850 |

| Physical Properties | Side surface Roughness Ra(μm) | 5-7 | / | GB/T 1031 |

| Mechanical Behavior | Tensile Strength (MPa) | 1000±100 | 1400±100 | GB/T 228.1 |

| Mechanical Behavior | Yield Strength (MPa) | 700±100 | 1150±100 | GB/T 228.1 |

| Mechanical Behavior | Elongation (%) | 27±5 | 15±5 | GB/T 228.1 |

| Mechanical Behavior | Hardness | 30±5HRC | 43±5HRC | GB/T 230.1 |

Nickel 3D Printing Capabilities

- Maximum Forming Printing Size Of Metal 3D Printer: 250x250x325mm;

- 3D printing layer thickness: 0.02mm~0.04mm;

- The Achievable Accuracy Of 3D Printing:Typical Accuracy: ±0.02-0.05 mm (Accuracy is related to geometry. It varies according to product size, printing direction, materials and post-processing methods.);

- Post-Processing: high temperature annealing, polishing, welding and other processing;

Certifications & Quality Printing

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Nickel 3D Printing Parts & Case Studies

The metal 3D printer distributes even layers of metallic powder and the powdered metal is selectively melted to previous layers, which allows 3D metal parts to be fabricated of a bed of powdered metal. Using metal 3D printing allows us to produce parts with complex geometries that using traditional manufacturing methods not capable of and with materials that are difficult to process. 3D printing metal materials including aluminum, stainless steel, cobalt chrome, nickel alloy, titanium, etc.