3D Printing For Tantalum – What Is Tantalum 3D Printing

Tantalum is a rare and valuable metal known for its high melting point, corrosion resistance, and biocompatibility, making it useful in various industries such as aerospace, electronics, and medicine. While 3D printing with tantalum isn’t as widespread as other metals like titanium or aluminum, there have been advancements in using tantalum for additive manufacturing purposes.

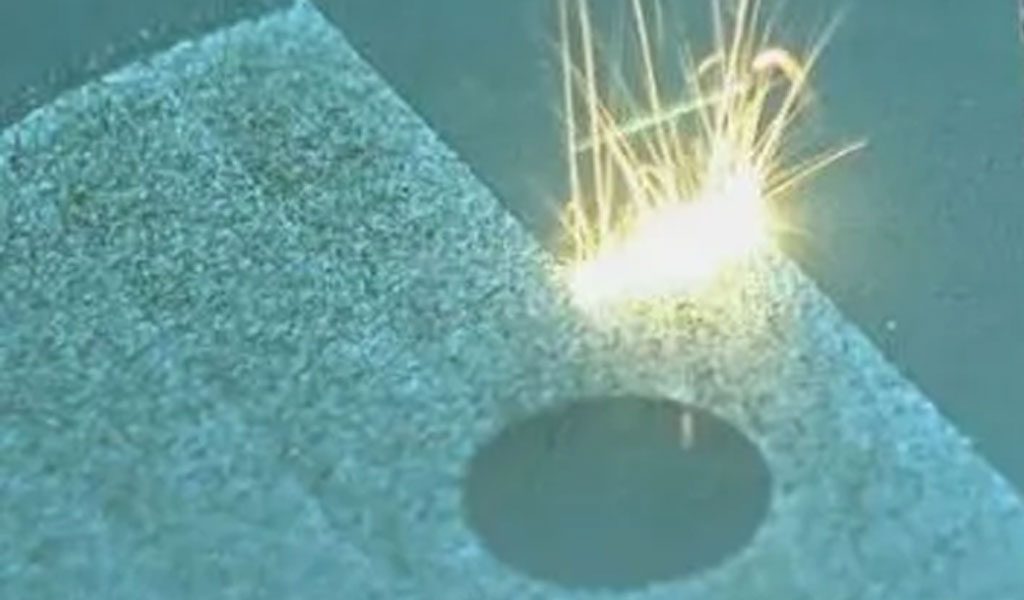

Tantalum isn’t as commonly used in 3D printing as some other metals due to its scarcity and cost. It’s often reserved for critical applications where its specific properties are necessary.The most common method for 3D printing with metals like tantalum is through powder bed fusion processes like selective laser melting (SLM) or electron beam melting (EBM).

These methods involve melting fine tantalum powder layer by layer to build the desired object.Tantalum’s high melting point (about 3,020°C or 5,468°F) presents challenges in terms of processing and handling during 3D printing. Additionally, its high reactivity with oxygen at high temperatures requires specialized processing in an inert atmosphere.Therefore, it’s typically used in highly specialized and critical applications where its unique properties are essential. As technology advances and research progresses, we may see more widespread use of tantalum in additive manufacturing.

Tantalum 3D Printing Services – 3D Printing Tantalum Parts

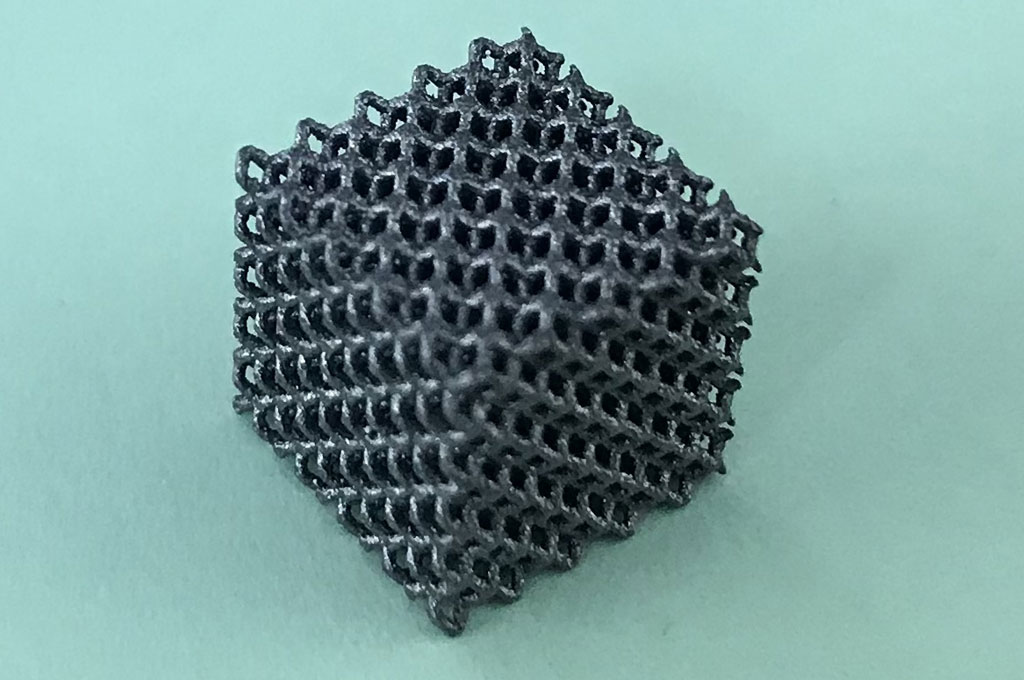

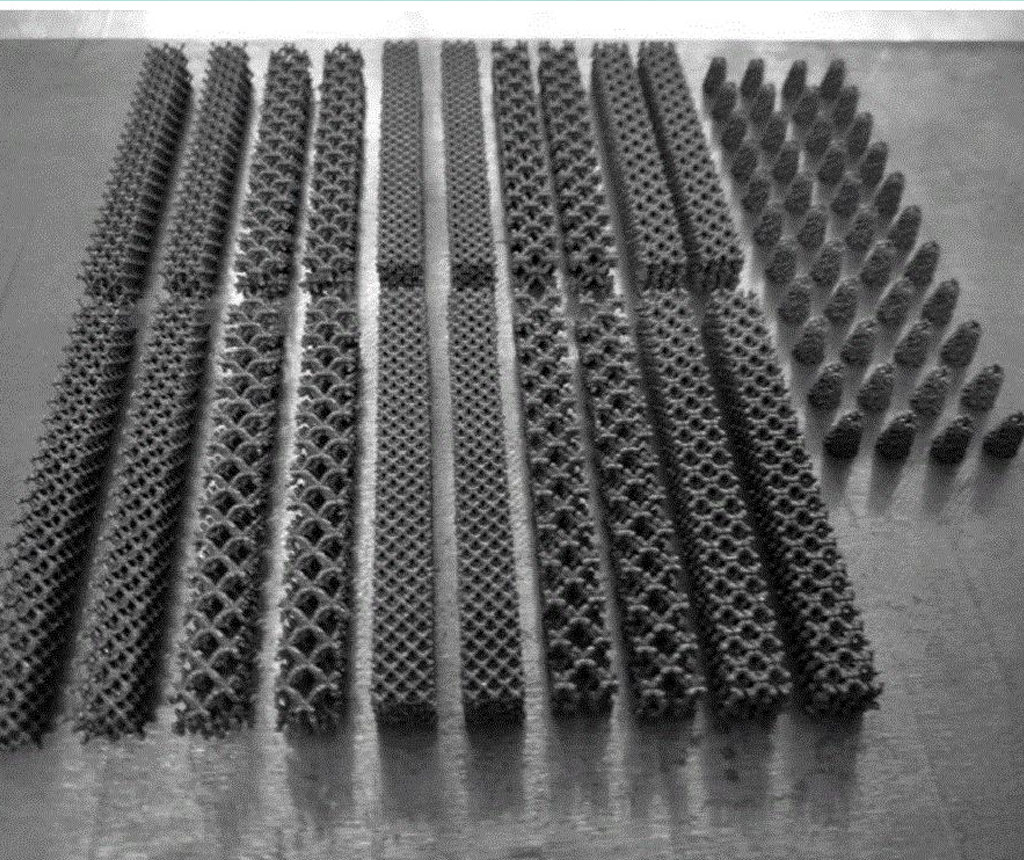

Tantalum’s properties, including its high melting point, corrosion resistance, and biocompatibility, make it attractive for specific applications that demand these characteristics.3D-printed tantalum parts find applications in industries such as aerospace for manufacturing components requiring high-temperature resistance and in medical implants due to tantalum’s biocompatibility.

Be-Cu prototype is an expert metal 3d printing company, with a great specialty in 3d printing pure tantalum. We offer high-quality tantalum parts 3d printing services to industries at highly competitive prices. With metal 3d printing equipment, our team of designers and engineers is always ready to take and process your order in the shortest time possible, reducing time to market.

Be-Cu prototype ongoing research and development aim to improve the 3D printing process for tantalum, exploring new techniques and methodologies to optimize its properties and reduce manufacturing costs.Our quote is completely free. And if you have any doubts about what technology will work best for you, our expertise is at your service.

Which Process We Tantalum 3D Printing With

The two primary methods for 3D printing with tantalum are:

- Selective Laser Melting (SLM): SLM involves melting and fusing fine layers of tantalum powder selectively using a high-powered laser according to the digital design. The laser selectively melts the powder, layer by layer, based on the 3D model, resulting in the creation of the desired component.

- Electron Beam Melting (EBM): EBM, similar to SLM, uses a high-energy electron beam to melt and fuse tantalum powder. This process occurs in a high vacuum, and the electron beam precisely melts the powder to create the desired shape.

Tantalum 3D Printing Capabilities

- Maximum Forming Printing Size Of Metal 3D Printer: 250x250x325mm;

- 3D printing layer thickness: 0.02mm~0.04mm;

- The Achievable Accuracy Of 3D Printing:Typical Accuracy: ±0.02-0.05 mm (Accuracy is related to geometry. It varies according to product size, printing direction, materials and post-processing methods.);

- Post-Processing: high temperature annealing, polishing, welding and other processing;

Certifications & Quality Printing

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Tantalum Powder For Biomedical Field

Tantalum and its alloys have found significant use in the biomedical field due to their biocompatibility, corrosion resistance, and radiopacity. Tantalum implants are particularly valued in orthopedic and dental applications.

Tantalum powder, often derived from tantalum ingots or produced through various methods like atomization or sintering, is used in additive manufacturing (3D printing) for fabricating custom implants. These implants can be tailored to fit a patient’s specific anatomical requirements, offering advantages in terms of precise fit and reduced risk of rejection.

Chemical Composition

| No., | C | O | N | H | Nb | Fe | Of | IN | Mo | And | In | Facing |

| T0966 | 100 | 300 | 100 | 15 | 1000 | 100 | 100 | 50 | 20 | 5 | 100 | Bal. |

| Powder | 10 | 50 | 30 | 10 | <10 | 30 | 10 | <30 | <20 | <30 | 10 | Bal. |

Powder Physical Properties

- Spherical rate: >90%

- Particle size: <105μm

- Liquidity: 7.5s/50g

- Bulk density: 9.3g/cm3

- Tap density: 9.8/cm3

Basically no irregular powder and satellite powder