What Is 5 Axis Turn-Mill Machining

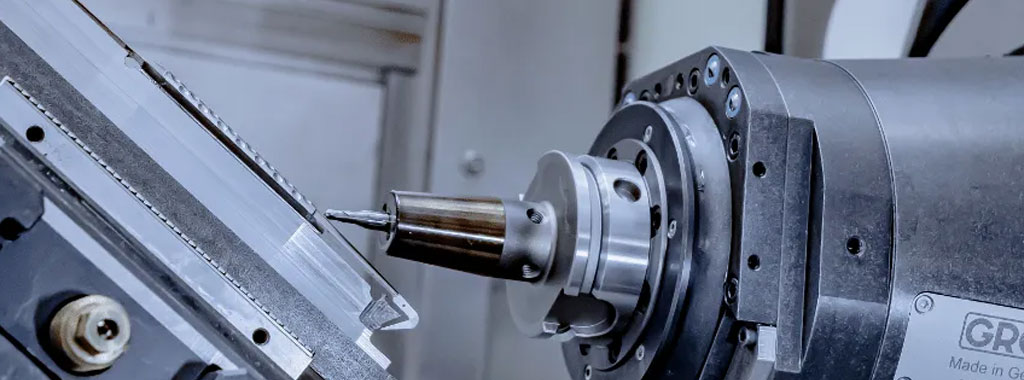

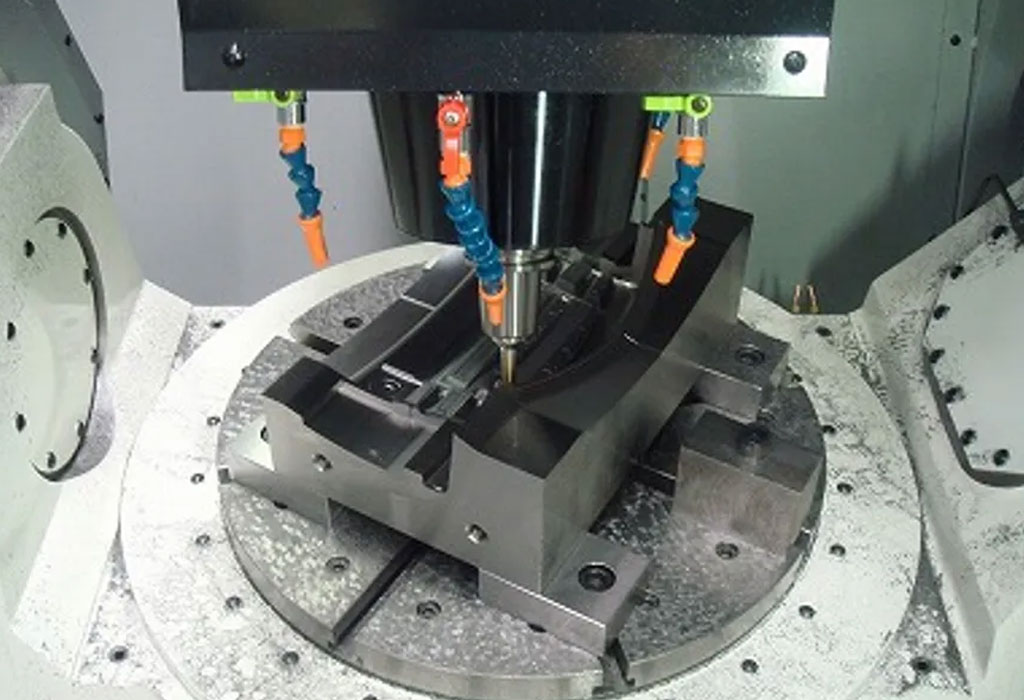

5 Axis Turn-Mill Machining technology is typical of multi-axis machining technology. Five-axis turning and milling center is the carrier of five-axis turning and milling technology, which is the collective name of a machine tool with turning function mainly, and integrated with milling and boring functions, with at least 3 linear feed axes and 2 circumferential feed axes, and equipped with automatic tool changing system.

This turning and milling machining center is developed on the basis of three-axis turning center, equivalent to a turning center and a machining center, is a composite machining technology developed in the 1990s, is a traditional mechanical design technology and precision manufacturing technology, based on the integration of modern advanced control technology, precision measurement technology and CAD / CAM application technology of advanced.

It is an advanced machining technology that integrates modern advanced control technology, precision measurement technology and CAD/CAM application technology based on traditional mechanical design technology and precision manufacturing technology. The advanced nature of the five-axis turning and milling center is shown in its design concept. In the usual concept of machining, the machining of 1 part, as little as one or two processes, as much as hundreds of processes, to be completed by the machining of multiple equipment, to prepare tools, fixtures and jigs. For complex parts, some sets of tooling preparation will take three to five months, even without considering the economic cost, three to five months is likely to miss many commodity opportunities and strategic opportunities.

In mass production industries such as automobiles and home appliances, automated production lines are widely used in order to improve efficiency and automation levels. The huge logistics system forms a very major part of the automatic line, and at the same time is a part that takes up money, occupies an area, and is also a part that is prone to failures, and the logistics is a big problem for the machining of complex shapes and surfaces. The multiple clamping and reference conversion of parts sometimes bring unnecessary processes, but also the loss of parts machining accuracy. Five-axis turning and milling machining center from the design concept to solve this problem, it is a clamping, complete the machining range of all or most of the processes, to achieve the leap from composite machining to complete machining.

The Advantage Of 5 Axis Turn-Mill Machining

Use 5 Axis Turn-Mill Machining equipment to mill slots, flatten surfaces, drill and tap holes and cut sharp edges. Some advantage of 5 Axis Turn-Mill Machining are following:

- Reduce the reference conversion, improve machining accuracy.

- Reduce the number of fixtures and fixtures and floor space.

- Shorten the production process chain and simplify production management

- Shorten the new product development cycle.

The Development Of 5 Axis Turn-Mill Machining

Five-axis turn-mill machining center from the generation of nearly 20 years of history, the technology has matured and is accepted and recognized by china and foreign users. In terms of trends, the main development is in the following directions.

1.Higher Process Range

By adding special function modules, more process integration is realized. For example, gear machining, internal and external grinding, deep hole machining, cavity machining, laser quenching, online measurement and other functions are integrated into the turning and milling center to truly achieve complete machining of all complex parts.

2.Higher Efficiency.

By configuring dual power heads, dual spindles, dual tool holders and other functions, it realizes simultaneous machining of multiple tools and improves machining efficiency.

3.Large-Scale.

As large parts are generally more complex structure, more parts and processes required to be processed, installation and positioning is also more time-consuming and difficult parts, and one of the main advantages of turning and milling composite machining is to reduce the parts in the multi-process and multi-process machining process of multiple re-installation adjustment and clamping time, so the use of turning and milling center for composite machining is more favorable. Therefore, the current five-axis mill-turn machining center is developing to a larger size. For example, the HTM125 series five-axis turning and milling center of Shenyang machine tool has a slewing diameter of 1250mm, and the machining length can reach 10000mm, which is very suitable for the turning and milling of large marine diesel engine crankshaft.

4.Structure Modularity And Function Can Be Quickly Reorganized

The function of five-axis turning and milling center can be quickly reorganized is an important condition that it can quickly respond to the market demand and seize the market, and the structure modularity is the basis for the function of five-axis turning and milling center can be quickly reorganized. Some technologically advanced manufacturers (such as DMG of Germany, WFL of Austria, MAZAK of Japan, etc.) have realized structural modular design for many of their products and are working toward how to realize the rapid reorganization of functions.

The advanced concept of 5-axis turning and milling technology is to improve product quality and shorten product manufacturing cycle time. Therefore, the application of this technology in the military, aviation, aerospace, shipping and some civil industry has considerable advantages, especially in the aerospace field in the machining of some complex shaped shaped parts more advantageous, so foreign countries have long adopted such equipment in the aerospace field in large numbers instead of traditional machining equipment, while the china in this regard is relatively backward, so we still need to learn from the advanced experience of foreign countries, and strive to In the field of five-axis turning and milling technology applications to change the backward situation.

5 Axis Turn-Mill Machining – 5 Axis Cnc Turn-Mill Machining Services

Product Accuracy Is Our Attitude,We offer 5 Axis Turn-Mill Machining services for precision parts. Meet your requirement on price and quality.Where We Build Your precision visions

Be-cu.com(Pintejin Group) is devoted to producing precision 5 axis turn-mill machining components, machined to the highest standards and backed by our ISO 9001:2015 certification.

Our team of skilled engineers and machinists work with our customers to create the specific precision components you need. Through over 30 years of experience in producing specialized precision components for industry, we will also provide guidance on how to improve the part itself if there’s an opportunity to do so.

Whether it’s machining process requirements, or dimensional efficiencies in finishing; This multi-disciplinary approach enables us to consistently and successfully meet or exceed your machining expectations.

Be-cu.com’s engineering team is constantly looking for new ways to improve and enhance the quality of our Precision CNC machining practices. ISO 9001:2015 certified with state of the art DMU And Mazak 5 axis Turn-Mill Machine centers, along with world class CMM (coordinate measuring machine) equipment, Be-cu.com’s customers can rest assured they are getting the best machining services for their high precision parts available.

Our Case Studies Gallery Of 5 Axis Turn-Mill Machining Services Parts

We are in the business of creating products that save you time and money. In addition to our Multi Axis Machining services, we provide laser cutting, sheet metal manufacturing, die casting, and 3d printing. All customers’ orders are inspected by our team to ensure they ship complete with hardware, finish, silk-screening, electronic component assembly, and testing.

Don’t see what you are looking for? Reach out to us and learn how we can work together to create what you need.

-

CNC Machining Bakelite Circuit Board Test Fixture

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt