What Is Wood CNC Machining

The evolution of CNC machining wood traces its roots back to the early 20th century, with the advent of numerical control systems designed to automate machining processes. The inception of these rudimentary systems laid the groundwork for the development of modern CNC technology, which found its niche in diverse industries, including aerospace, automotive, and of course, woodworking.The pivotal moment in the history of CNC machining wood occurred in the mid-20th century, with the emergence of computer-controlled routers and mills. These machines, equipped with precise motors and cutting tools, revolutionized the woodworking industry by offering unparalleled accuracy, repeatability, and efficiency in wood processing.

In the realm of woodworking, precision, efficiency, and innovation intersect at the heart of CNC machining. The advent of Computer Numerical Control (CNC) technology has ushered in a new era, redefining the boundaries of craftsmanship and enabling artisans to delve deeper into the intricacies of wood manipulation.

CNC Wood Machining Service – CNC Machining Wood Parts

At the heart of CNC machining wood lies a relentless pursuit of precision, manifested in the meticulous calibration of machine components, the optimization of cutting parameters, and the refinement of toolpath algorithms. Through careful attention to detail, artisans are able to achieve levels of accuracy and repeatability once thought impossible.

Fully-equipped facilities and skilled operators help us provide precision wood machining parts such as plywood, hardwoods, melamine and more products. All the machined parts supplied by Be-Cu come with the highest safety and premium quality. Whether the regular wood toy or complex constructions are made from durable materials for lasting a long time.

Explore our CNC Wood Services, Where Imagination Meets Precision.Bring Your Custom Wood Projects to Life.If you need spare parts for custom, our precision machining will ensure each component work perfectly with other sections of your equipment.

As a reliable CNC wood parts manufacturer and supplier in China, our purpose is to get optimal results with the least money. Be-Cu’s CNC systems feature up to three workstations which will allow you to automate most of your woodworking task. According to the needs of clients, we’ll provide CNC design and production for all kinds of machinery parts and various wood products, using lathes, horizontal and vertical mills, 5-axis CNC machining centers, and other equipment.

The CNC routing machine cuts at a tolerance of (+/-0.001” for plastics, +/- 0.005 for most woods. Natural swelling and shrinking of wood can make a very tight tolerance unnecessary) .Thank you for your time and consideration. We eagerly anticipate the opportunity to showcase the capabilities of our wood CNC Machining Service and demonstrate how it can meet and exceed your expectations.

CNC Woodworking Disciplines In Be-Cu Prototype Shop

Our CNC machines are able to achieve sharp edges and tight tolerances on materials that would be otherwise affected by the heat of a laser. Our online CNC wood machining service will ensure your parts are cut to spec every time.

- CNC Turning

- CNC Part Processing

- CNC Joinery

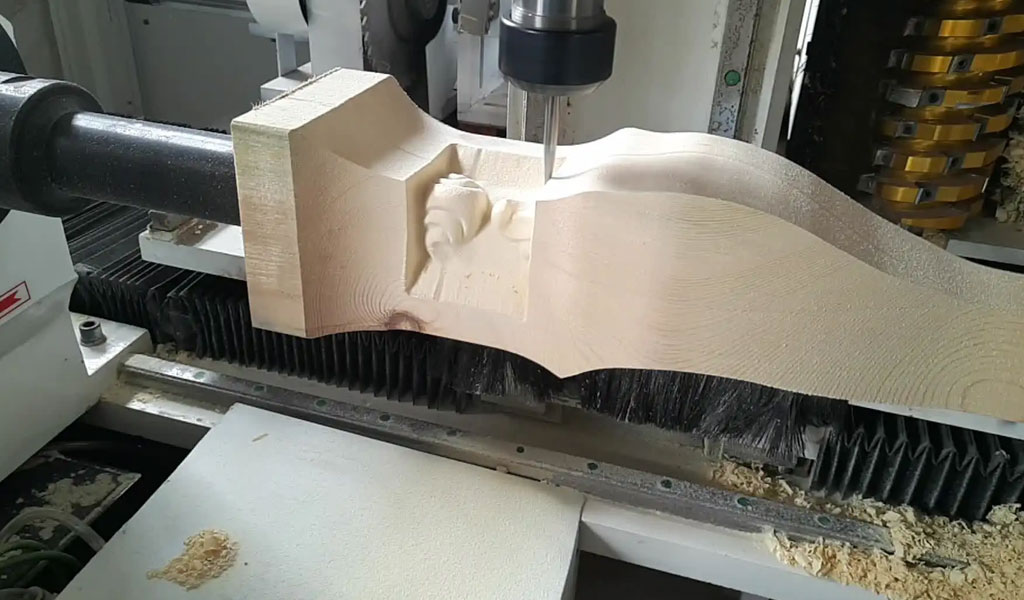

- CN 3D Carving

- CNC Wrapped Carving

- CNC Molding

- CNC Routing

- CNC Inlay

- CNC Sheet Processing

Tailoring to Your Needs with a Variety of Materials

we specialize in custom woodworking. We offer a wide range of wood materials to cater to your specific requests, ensuring your designs come to life exactly as you envision them.

Camphor Wood

Hickory Wood

Yew Wood

Water Oak

Maple Wood

Black Walnut Wood

How To CNC Wood Machining?

CNC machining wood transcends the realms of traditional woodworking, empowering artisans to push the boundaries of creativity and craftsmanship. From intricate carvings to seamless joinery, the possibilities are as limitless as the imagination itself.

- Design Phase: The journey begins with the conception of a design, whether hand-drawn or meticulously crafted using Computer-Aided Design (CAD) software. This digital blueprint serves as the guiding light throughout the machining process, dictating every facet of the final masterpiece.

- Material Selection: Central to the artistry of CNC machining wood is the careful selection of timber, each species imbued with its unique characteristics and aesthetic appeal. Whether it be the rich hues of mahogany or the intricate grain patterns of oak, the choice of material sets the stage for the ensuing creative endeavor.

- Toolpath Generation: With the design finalized and the material selected, the next step involves generating toolpaths, intricate algorithms that dictate the trajectory of the cutting tool as it traverses the surface of the wood. These toolpaths are optimized to maximize efficiency while ensuring precision and surface quality.

- Machining Process: With the stage set and the tools poised for action, the CNC router springs to life, its mechanical prowess brought to bear upon the raw timber. With each pass of the cutting tool, the design begins to take shape, revealing the intricate interplay of form and function.

- Finishing Touches: As the machining process nears completion, attention turns to the finer details, from sanding and smoothing to staining and sealing. These finishing touches impart a sense of refinement and elegance, elevating the final piece from mere woodwork to a true work of art.

Why Choose Our Wood Cnc Machining Service?

- Save time and money for your wood project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of wood grades and plastic materials can be machined

- Custom complex wood machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Wood Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and cnc routing are today considered the most economic way to make wood prototypes.Our company has rich experience making wood concept models and precise functional components. Understanding the properties of different wood, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on wood. Be-cu prototyping company provides a range of solutions for the machining of wood parts.