Plywood For Laser Cutting

From intricate artistic designs to cutting-edge architectural marvels, the utilization of plywood has transcended mere carpentry. With the advent of laser cutting technology, the potential of plywood has been magnified manifold. Laser cutting has not only revolutionized the manufacturing process but has also transformed the creative possibilities in various industries.

Plywood, a composite wood product made from thin layers of wood veneer,with adjacent layers having their wood grain rotated up to 90 degrees to one another,has been a fundamental component in the construction, design, and manufacturing industries. It is known for its durability, flexibility, and cost-effectiveness, making it a preferred material for an array of applications.

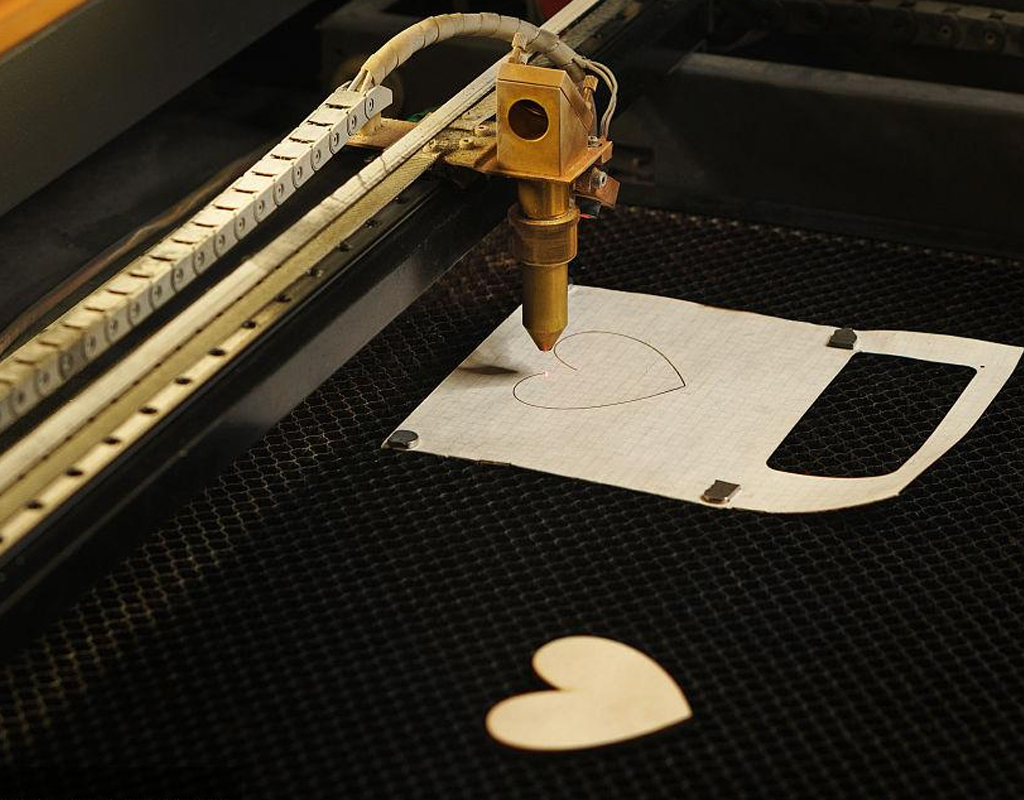

The integration of laser cutting technology into the woodworking industry has ushered in a new era of precision and creativity. Unlike conventional cutting techniques that rely on saws or blades, plywood laser cutting employs a high-powered laser beam to vaporize, burn, or melt the material, resulting in clean and precise cuts with unparalleled intricacy.

Wood Laser Cutting Service – Custom Plywood Laser Cutting Manufacturer

Be-Cu Prototype is now offering complete Laser Wood Cutting And Plywood Precision Cut Service.

Be-Cu.com

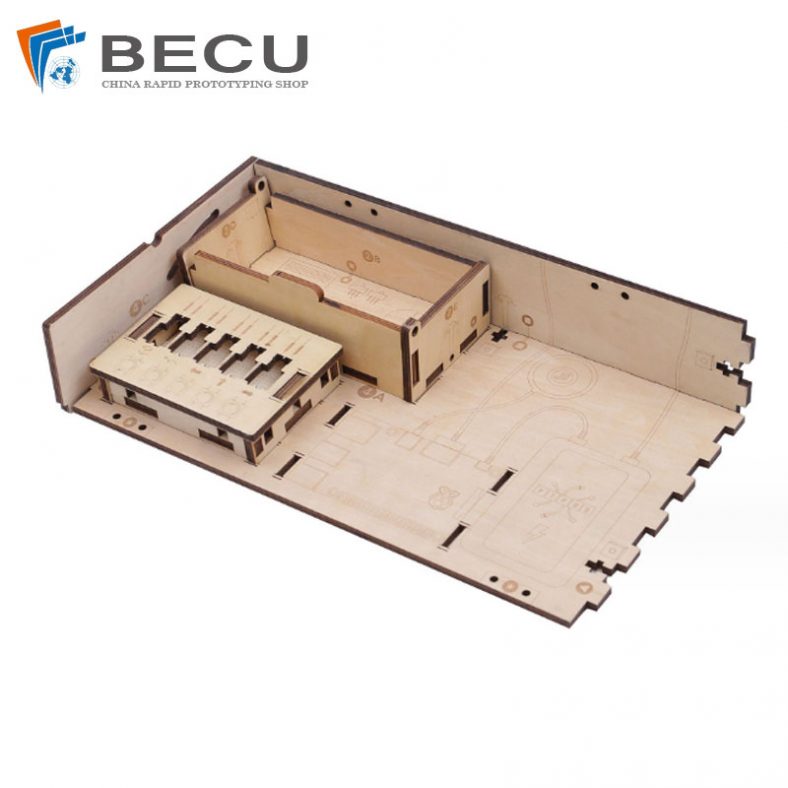

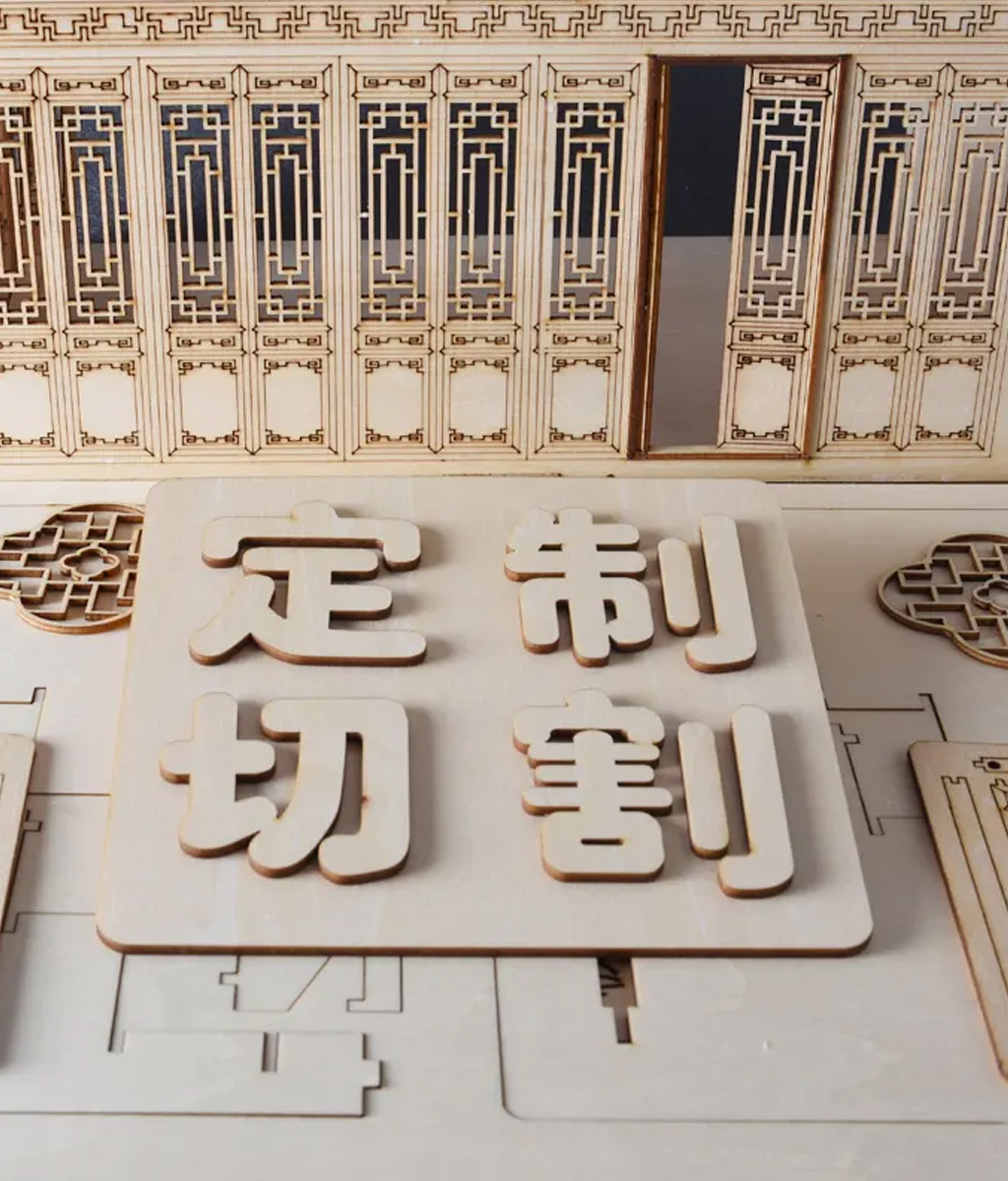

Be-Cu has the unique ability to Laser Cut and Laser Engrave in a single process, producing exceptional quality products that are cost effective. Our plywood laser cutter can cut, shape, or drill holes, grooves, and pockets, as well as perform lettering, engraving, and edge profiling with pinpoint accuracy.

With the help of our adept draftsmen and programmers, any CAD drawing or concept can become a fabricated design. We utilize programs like WoodCAD|CAM and Cut Rite to engineer and manufacture even the most extraordinary projects or custom designs on our oversized 5′ x 10″ machine. Our CNC Machine handles any type of flat material, from hardwoods, wood composites, such as MDF, particle board, plywood, melamine, and laminate, to plastics like acrylic, Delrin, HDPE, and phenolic.We process both short run and large full production cycles, no job is to large or small.Whatever the project,Our Max Working Range – x y x-48″ y-36″ and Tolerance to+/- .002″, this transformative panel cutting process will allow you to complete it with unparalleled efficiency. Our work is completely based on your digital file to eliminate cutting errors. You can upload your CAD file to get a fast and free online quote, we’ll keep track of all the details and get your design to processing in a short time.

CO2 Laser Cutting Plywood

Co2 laser cutting plywood refers to the process of using a carbon dioxide (CO2) laser system to cut plywood sheets with precision and accuracy. This technology is widely used in various industries and applications for its ability to produce clean, intricate cuts and detailed engravings on plywood and other materials. including but not limited to:

- Custom signage and lettering

- Architectural models

- Art and craft projects

- Inlays and marquetry

- Jigsaw puzzles

- Furniture manufacturing

- Prototyping

- Decorative panels and screens

- Scale models and dioramas

- More

CO2 laser cutting provides high precision and speed, making it a cost-effective solution for many industries. It can handle intricate designs and large-scale production runs with ease.

Plywood Laser Cutting Thickness

The choice of plywood thickness for laser cutting depends on the specific project and its requirements. Different thicknesses are suitable for various applications, from intricate details to structural support. Here’s a breakdown of common plywood thicknesses for laser cutting:

Laser Cut 5mm Plywood

Often used for craft projects, jewelry, and small-scale models.

The thin profile allows for detailed cuts and engraving.

Laser Cut 3mm Plywood

Ideal for crafting, scale models, and decorative items.

Offers a balance between detail and structural integrity.

Laser Cut 1/2″Plywood(12.7mm)

Often used for craft projects, jewelry, and small-scale models.

The thin profile allows for detailed cuts and engraving.

Laser Cut 1/4″Plywood(6.35mm)

Commonly used in laser-cut puzzles, decorative panels, and lightweight furniture.

Laser Cut 3/4″Plywood(19.05mm)

Used in projects such as tabletops, cabinets, and heavy-duty structural components.

Can handle engraving but may require adjustments for intricate cuts.

1/8″ (3.175mm) Plywood for Laser Cutting

Commonly used in model making, crafting, and custom prototypes.

Suitable for intricate designs and engraving.

The choice of plywood thickness depends on the specific requirements of your project, including the level of detail, structural needs, and the material’s intended use. Always consult the manufacturer’s guidelines for your laser cutting machine and perform test cuts to determine the optimal settings for your chosen plywood thickness.

Common Wood Used in Laser Cut – Plywood Types,Grades,Applications

Selecting the right type of plywood for laser cutting is crucial for achieving precise, clean, and aesthetically pleasing results. Each type of plywood has its unique characteristics and is suitable for different applications. In this section, we will discuss various types of plywood commonly used in laser cutting, including Birch Plywood, MDF (Medium-Density Fiberboard), Oak Plywood, Maple Plywood, Cherry Plywood, Walnut Plywood, Pine Plywood, and Poplar Plywood.

Birch Plywood

Laser Cutting Suitability: Birch plywood is well-suited for laser cutting, as it cuts cleanly and produces precise edges. It is suitable for a wide range of applications, including model making, architectural prototypes, and intricate designs.

MDF (Medium-Density Fiberboard)

Laser Cutting Suitability: MDF is an excellent material for laser cutting. Its smooth surface allows for sharp engraving, and it is often used for signage, puzzles, and decorative items. However, it produces more smoke and residue during cutting.

Oak Plywood

Laser Cutting Suitability: Oak plywood can be used in laser cutting, but it’s denser than some other types, which may require adjustments to laser settings. It is often chosen for projects where aesthetics and strength are important, such as custom furniture and cabinetry.

Maple Plywood

Laser Cutting Suitability: Maple plywood is a suitable choice for laser cutting, especially in applications that require a light-colored finish. It is often used in architectural models, crafting, and decorative items.

Cherry Plywood

Laser Cutting Suitability: Cherry plywood can be used in laser cutting projects that demand a reddish-brown finish. It is often selected for items like jewelry boxes, decorative panels, and cabinetry.

Walnut Plywood

Laser Cutting Suitability: Walnut plywood is suitable for laser cutting and is often chosen for projects where a dark wood finish is desired, such as high-end furniture, custom cabinetry, and decorative pieces.

Pine Plywood

Laser Cutting Suitability: Pine plywood is less dense than hardwoods, making it easier to cut. It’s used in applications where structural strength is not the primary concern, such as laser-cut signage, craft projects, and decorative items.

Poplar Plywood

Laser Cutting Suitability: Poplar plywood is often used for laser cutting due to its ease of cutting and smooth surface. It’s suitable for applications like model making, crafting, and custom prototypes.

Selecting the right type of plywood for your laser cutting project depends on your specific requirements, including aesthetics, strength, and the complexity of your design. Understanding the characteristics of these various types of plywood will help you make an informed choice and achieve the best results in your laser-cutting endeavors.

Benefits Of Laser Cutting Plywood

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient Laser Cut factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

Outstanding Laser Cutting Plywood Case Studies

Using our top of the plywood laser cut service allows us to create unique design and features.We provide custom precision cutting services for a wide range of plywood. Using our high speed wood laser cutter allows us to complete projects in a minimal amount of time while providing precision cuts and high yields limiting material waste.Check out our extensive gallery that shows precision wood laser cutting prototypes and parts from our valued customers.