Why Choose Brass For Precision Stamping

Metal stamping really came into its own during the industrial revolution. It started when manufacturers used the process to make bicycle parts. The manufacturers found it cheap and efficient and soon began stamping as much metal as possible. At the turn of the 20th century, Henry Ford turned to metal stamping for the parts of his car, the Model T.

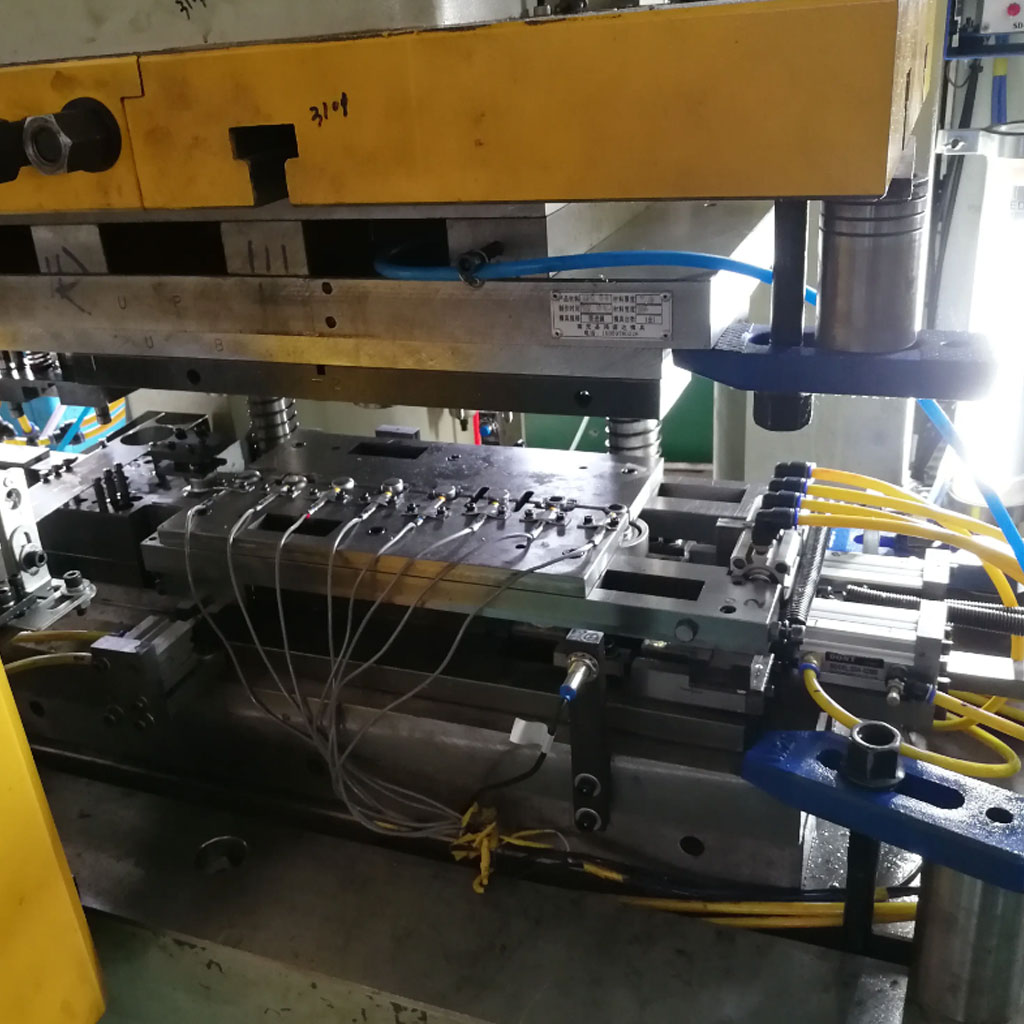

Since then, the metal stamping process has not changed much, except in terms of automation, power sources (electric, pneumatic, hydraulic, etc.) and the materials that can be used for stamping. Among these, brass has been around for decades as a special stamping material. Brass is an alloy consisting mainly of copper and the aforementioned zinc. Brass is somewhat resistant to corrosion, but not super strong. It is, however, aesthetically very pleasing. It is therefore best used when a manufacturer wants to make decorative stampings. In addition, jewellery, plumbing and household fixtures are often made from brass stampings.

Professional Brass Stamping Manufacturer -Precision Stamping Brass Parts

Be-cu manufactured the stamping brass parts with features such as high electrical conductivity, high corrosion resistance, tarnish resistance, shiny gold-like surface, good chemical resistance, wear resistance, scratch resistance, and more.Brass stamping technologies could be applied to different application include hinges, kick plates, instrument frames, gutter accessories, automotive parts, machine parts, decorative parts, elevator components, electrical parts, and so on.Aside from that, the stamping brass can also be cut, welded, bent or punched according to your specifications. It can be fabricated into different parts such as complex parts due to their malleability.

Moreover, the brass stamping parts can be finished with various surface treatments such as brushed finish, satin finish, bright annealed finish, mill finish, custom finish, etc.If you got questions regarding Be-cu brass stamping fabrication, do not hesitate to leave us a message!

The Brass And Brass Alloy Grades Of Precision Stamping

Brass Stamping is a process of mass producing parts using different grades of brass metal sheets. At Be-cu.com(Pintejin Group), we use H85, H68, and H62 brass alloy for the pressing.

- H85 brass is composed of 85% copper and 15% zinc alloy, has good mechanical properties and corrosion resistance, excellent cold working properties, good hot forming properties

- Composed of 68% copper and 32% zinc, H68 brass has good plasticity and high strength, good machinability, easy welding, corrosion resistance, good hot and cold processing performance.

- Composed of 62% copper and 38% zinc. H62 brass has high strength, good thermoplasticity, easy welding, good corrosion resistance, easy dezincification and stress cracking in some cases.

Stamping Brass Applications Within Be-cu.com

As a leader in brass-stamping manufacturing technology, we focus on precision metal stamping and micro-drawing parts manufacturing, and our products are widely used in electronic parts, CCTV device components, metal terminal, etc.Be-cu’s brass stamping parts and small deep drawing parts can be used in a variety of applications, including:

- The stamping brass can be used for a variety of applications as a result of its beautiful appearance and versatility. It can be used for the interior decoration of many buildings and elegant venues. Moreover, its features such as easy-to-cut, easy machining, and high ductility make them ideal for various decoration applications.

- In addition, due to its excellent corrosion resistance, the sheet metal brass can also be used in applications that require low friction. Some of the applications that include low friction are fasteners, appliance parts, connectors, electrical applications, mechanical applications, ammunition components, and many more.

- The brass stamping can also be used for construction, plumbing areas, builder’s hardware, light fixtures fabrication, and so on.

The Advantage Of Brass Stamping

Metal Stamping offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, brass stamping tools are typically 30% of the cost.

- Shorter Lead Times – The Brass Stamping process amounts to significantly shorter turnaround times – tools and stamping components can be available within weeks rather than months.

- Maximum Design Flexibility – Brass Stamping mold can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – Brass stamping produces smooth, durable objects without seams or sheet metal, for parts require feature superior strength and great aesthetics.

Manufacturing Of Custom Brass Stamping Parts

If you need assistance on your custom Brass Stamping projects, we will be one of the most capable and affordable production sources with our technology, experience, and skills. Our strict implementation of ISO9001 quality system standards, and the combination of efficient production processes and flexible custom engineering enable us to deliver complex projects in short turnaround times and provide excellent product quality.

Top Brass Stamping Parts And Case Studies

You have a complex Brass part design, Pintejin Group(Be-cu.com) can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.