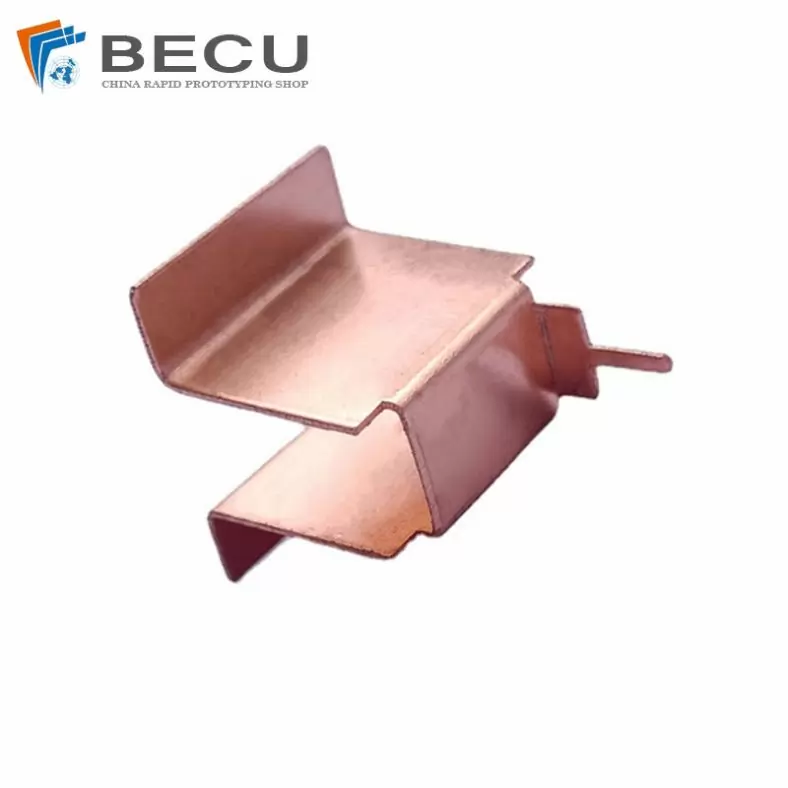

Precision Stamping Copper Alloy

Copper is a soft, malleable metal that can be easily shaped when heated and cooled, which making it one of the most versatile and widely used stamping materials.

Copper and copper alloys are well suited for stamping applications, Copper stamping is the specialized precision punching of customer designed copper components from cold headed sheet, copper sheet, or solid copper sheet. Copper is a very difficult metal to machine and requires specialized process knowledge for manufacturing.

One of our specialties at Be-cu.com(Pintejin Group) is copper stamping, which we perform with specialized equipment and software to produce high quality copper products at competitive prices.

Beryllium Copper Stamping

Beryllium Copper has unique benefits that make it a great precision stamping material and suitable for different applications, including good corrosion resistance, ductility, heat, and electrical conductivity and is very malleable. Precision parts can be produced with Beryllium Copper stamping, ensuring high consistency and accurate specifications.

Beryllium copper stamping is mainly used for various advanced elastic components, especially various components that require good conductivity, corrosion resistance, wear resistance, cold resistance and non-magnetic, and are widely used as diaphragm boxes, diaphragms, bellows, micro switches Wait.

The Copper Alloy Grades Of Precision Stamping

Four basic types of Copper are used in the stamping industry: pure copper,brass,beryllium copper and tellurium copper, each of which varies slightly in composition and, consequently, characteristics. These differences make them suitable for different applications. At Be-cu.com(Pintejin Group), we provide the most popular copper alloys on the market in order to meet your business needs. These alloys include:

- Copper alloy 110 is an extremely popular copper stamping alloy, with a wide range of applications due to its high corrosion resistance,

- C2200 super soft marine brass has fine luster, good workability, extensibility and corrosion resistance

- C2600H brass has very good plasticity (the best among brass) and high strength, good machinability, easy welding, very stable to general corrosion, but prone to corrosion cracking.

- C2680 brass has high strength, high hardness and strong chemical corrosion resistance. There are also outstanding mechanical properties of cutting

- C2600 brass, with very good plasticity (the best among brass) and high strength.

- C5191H Phosphor bronze is generally used for terminals that require elasticity.

- Tellurium copper alloy 145 (TeCu) is considered a hard-stamping copper alloy, ideal for parts that require extensive stamping, corrosion resistance, or high conductivity.

- Beryllium copper alloy 172 (BeCu) is one of the highest strength copper alloys, ideal for parts that require high strength and electrical conductivity

- Beryllium copper alloy 173 (BeCu) is a free-machining copper alloy, ideal for parts that require very high strength and stiffness

- Beryllium copper alloy 175 (BeCu) is a free-machining copper alloy, ideal for parts that require high strength and stiffness. It has excellent electrical conductivity

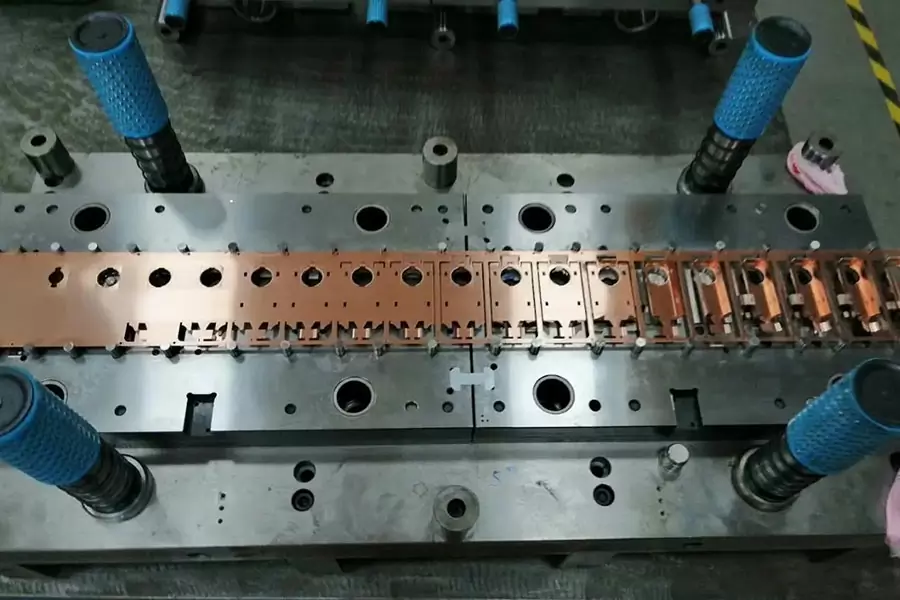

Our specialty in-house tooling process produces fast turnaround times and strict standards of quality for short run stamped parts and medium run stampes parts. Our mission is not just to produce the parts you need but also to develop a successful long-term partnership with your business.

Copper Stamping Services – Precision Stamping For Copper

As a precision stamping and fabrication company, Be-cu.com(Pintejin Group) offers copper stamping services that can manufacture stamping copper parts in almost all sizes and shapes, whether you require products for decorative purposes or industrial applications. Capable of stamping parts from 3 to 400 mm sizes and 35 to 700 tons press rating. Tolerance ranges up to +/-0.005 mm. Production methods are progressive and compound die, coining, compression, continuous, deep drawing, fine blanked, fourslide, fully sheared, laminating, punch press and robotic stampings. Additional services such as grinding, drilling, finishing, consulting, deburring, labeling and plating provided.

We can stamping a wide selection of custom precision stamping copper parts, such as plates, fixtures, shields, brackets, etc.Whether you need a single prototype or volume production runs, we Be-cu offers copper fabrication services from laser cutting to punch pressing to tube bending and more,welcome to send your inquiry.

The Advantage Of Copper Stamping

Metal Stamping offers a range of advantages to those looking for a very versatile, streamlined process, including:

- Lower Costs – Compared to the tools employed in alternative forming methods, copper stamping tools are typically 30% of the cost.

- Shorter Lead Times – The copper stamping process amounts to significantly shorter turnaround times – tools and stamping components can be available within weeks rather than months.

- Maximum Design Flexibility – Copper Stamping mold can be quickly and easily changed to accommodate evolving product designs, enabling flexibility when it’s needed most.

- Seamless, High-Quality Construction – Copper stamping produces smooth, durable objects without seams or sheet metal, for parts require feature superior strength and great aesthetics.

Manufacturing Of Custom Copper Stamping Parts

If you need assistance on your custom Copper Stamping projects, we will be one of the most capable and affordable production sources with our technology, experience, and skills. Our strict implementation of ISO9001 quality system standards, and the combination of efficient production processes and flexible custom engineering enable us to deliver complex projects in short turnaround times and provide excellent product quality.

Our Parts Case Studies Gallery Of Copper Stamping

We perform an efficient, accurate, and cost-effective process in-house to provide superior product results for your copper stamping.Whether you require punching copper pieces or custom copper parts for your automotive, aerospace applications or medical device component, we can easily help you. With our expertise in precision copper stamping and the ability to integrate external combined processes, we can ensure the best performance for your stamping copper projects.