Bronze Sheet Metal Fabrication

Bronze, a copper alloy typically containing tin, has been a favored material for its unique combination of strength, corrosion resistance, and aesthetic appeal.

In the world of metal fabrication, bronze holds a special place, as artisans and engineers have harnessed its unique properties to create awe-inspiring works of art and functional masterpieces.

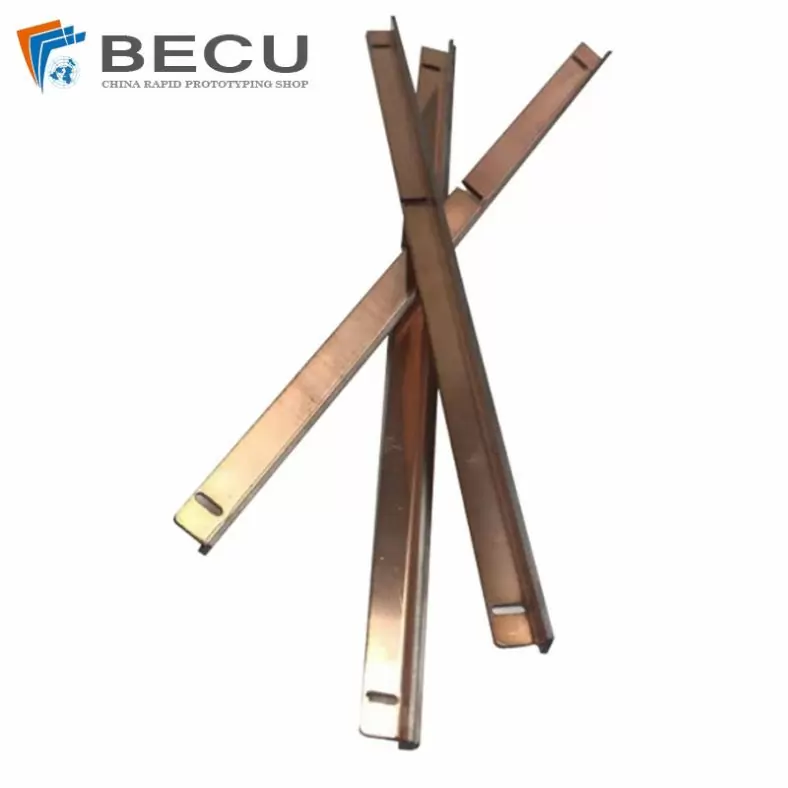

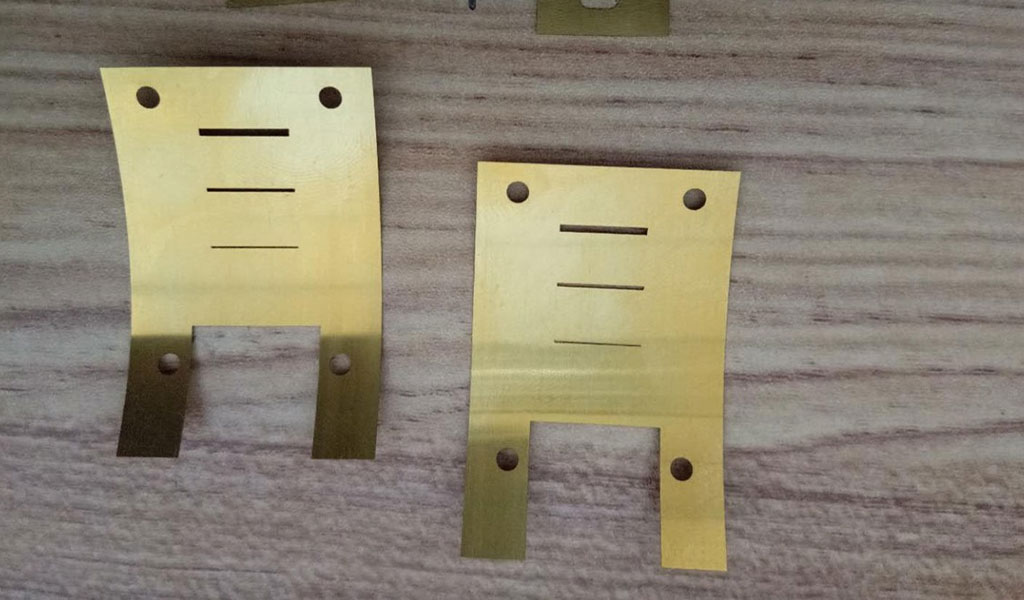

Bronze sheet metal fabrication is a process that involves the shaping, cutting, and forming of bronze sheets into various objects or parts. Bronze is an alloy primarily composed of copper and tin, and it has a distinct reddish-brown color. Bronze is valued for its durability, corrosion resistance, and attractive appearance, making it a popular material for a wide range of applications,from decorative art pieces and architectural elements to functional parts like gears, bearings, and electrical connectors. The exact methods and techniques used in bronze sheet metal fabrication will depend on the specific project’s requirements and the skills of the fabricators.

Bronze Grades Used During Sheet Metal Fabrication

Bronze is a versatile and durable material used in sheet metal fabrication for various applications, particularly when corrosion resistance, electrical conductivity, and an attractive appearance are required. The specific grades and alloys of bronze used in sheet metal fabrication can vary depending on the project’s requirements, but here are some common bronze grades and their applications:

C51000 (5% Phosphor Bronze)

C52100 (8% Phosphor Bronze)

C61300 (Aluminum Bronze)

C65500 (Silicon Bronze)

C17200 (Beryllium Bronze)

C75200 (Nickel Silver)

The choice of bronze grade depends on factors like the desired mechanical properties, corrosion resistance, and the specific application of the fabricated part. It’s important to consult with material experts or suppliers to select the right bronze alloy for your project, taking into account factors like conductivity, strength, and the environment in which the sheet metal will be used.

Custom Bronze Sheet Metal Fabrication Service In China

Be-Cu is a pioneering bronze fabrication company that has been at the forefront of the industry for over three decades. Renowned for our commitment to precision, quality, and innovation, we have earned a stellar reputation in the market. Our unwavering dedication to excellence and customer satisfaction has enabled us to become a trusted partner for businesses seeking top-tier sheet metal solutions. With a highly skilled workforce, cutting-edge technology, and a passion for excellence, we have consistently delivered superior products and services, exceeding the expectations of our clients.Bronze sheet metal fabricated parts have a wide range of applications due to the unique properties of bronze, which includes its corrosion resistance, malleability, and attractive appearance. Here are some common uses of bronze sheet metal fabricated parts:

- Architectural Elements: Bronze is often used in architectural applications for decorative elements like ornamental facades, handrails, door handles, and grilles due to its aesthetic appeal and resistance to weathering.

- Sculptures: Many sculptures and art pieces are crafted from bronze due to its ability to capture fine details, its durability, and its natural patina that develops over time.

- Musical Instruments: Bronze is used in the construction of musical instruments, such as cymbals, bells, and brass instruments like trumpets and trombones due to its unique acoustic properties.

- Marine Components: Bronze is highly resistant to corrosion, making it a popular choice for marine components like propellers, portholes, and ship fittings.

- Electrical Contacts: Bronze is an excellent electrical conductor, which makes it suitable for electrical connectors, switches, and other electrical components.

- Fasteners: Bronze fasteners are used in applications where corrosion resistance is crucial, such as in marine environments, as well as in historical restoration work.

- Coins and Medals: Many coins and commemorative medals are made from bronze due to its durability and the ability to produce intricate designs.

- Plumbing and Piping: Bronze is used for plumbing fixtures, valves, and fittings due to its resistance to corrosion and ability to withstand high-pressure environments.

- Automotive Parts: Some automotive parts, particularly in vintage or classic cars, are made from bronze, including bushings, bearings, and decorative components.

- Jewelry: Bronze is used in jewelry making for its unique color and appearance. It’s often used as an alternative to more expensive metals like gold.

- Aerospace Components: In some aerospace applications, bronze is used for specific components where its properties, such as low friction, are advantageous.

- Antique Restoration: Bronze sheet metal fabricated parts are used in restoring antique furniture, lighting fixtures, and architectural details to maintain their historical appearance.

- Coinage: Bronze coins are common in many countries and often have historical or commemorative significance.

- Bronze Bushings and Bearings: In machinery and equipment, bronze bushings and bearings are used to reduce friction and provide a durable, self-lubricating surface.

- Gears and Gearboxes: Bronze is used for gears and gearboxes in various applications, particularly where there’s a need for wear resistance.

- Decorative Hardware: Bronze sheet metal is used for creating decorative hardware items like knobs, handles, and pulls for cabinets and furniture.

- Sundials: Bronze is a popular material for crafting sundials due to its durability and the ease with which it can be shaped into intricate designs.

- Clock Mechanisms: Some antique and decorative clocks use bronze components, especially in their inner workings.

Bronze’s versatility and unique combination of properties make it a valuable material in various industries and applications, especially when a balance of durability, aesthetics, and corrosion resistance is required.

Be-Cu Bronze sheet metal fabrication company are a partner dedicated to your success. Be-Cu prototype has an experienced team of design experts who will create various product design and manufacturing solutions through CAD/Solidworks, and aesthetic designs for various application scenarios.With a rich history, a passionate team, and an unwavering commitment to quality, we are ready to tackle your most demanding fabrication challenges. Contact us today and experience the difference.

Why Use Our Bronze Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal bronze parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication bronze to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off Bronze laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom Bronze laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other mild steel sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Our Case Studies Gallery Of Bronze Sheet Metal Fabrication

At Be-cu.com, we are highly experienced in manufacturing custom steel sheet metal parts for demanding applications. By providing a cost-effective fabrication service that doesn’t sacrifice precision or quality, we benefit our customers by making their design ideas for crucial parts and project components become a reality.For more case studies about our services, see the products list below and contact us directly.