Titanium Sheet Metal Fabrication

Titanium sheet metal fabrication is the process of transforming titanium sheets into various desired shapes and structures through cutting, bending, shaping, and assembling techniques. Titanium is a strong, lightweight, and corrosion-resistant metal that is often used in aerospace, automotive, medical, and other industries where these properties are crucial.Titanium sheet metal fabrication requires specialized equipment, skilled technicians, and a deep understanding of the unique properties of titanium.

Due to its high strength-to-weight ratio and corrosion resistance, titanium is often used in applications where lightweight yet strong components are essential, such as aircraft components, medical devices, marine equipment, and high-performance sports equipment.

Benefits of Titanium In Sheet Metal Fabrication

Titanium offers several benefits when used in sheet metal fabrication, making it a preferred choice for various industries and applications. Here are some of the key advantages of using titanium in sheet metal fabrication:

- High Strength-to-Weight Ratio

- Corrosion Resistance

- Titanium is biocompatible

- Excellent Heat Resistance

- Low Thermal Expansion

- Non-Magnetic

- The long lifespan of titanium components, coupled with its recyclability, makes it an environmentally friendly choice.

The Titanium Alloy Grades Of Sheet Metal Fabrication

Titanium alloys used in sheet metal fabrication come in various grades, each designed to offer specific properties suitable for different applications. Here are some common titanium alloy grades used in sheet metal fabrication:

Grade 1 (Ti-CP):

- Commercially Pure Titanium

- Good corrosion resistance

- Excellent formability and weldability

- Soft and ductile

- Used in applications where corrosion resistance is essential, such as chemical processing equipment and marine components.

Grade 2 (Ti-CP):

- Commercially Pure Titanium (similar to Grade 1)

- Slightly stronger than Grade 1

- Widely used in similar applications as Grade 1, including chemical and marine industries.

Grade 5 (Ti-6Al-4V):

- Titanium Alloy with Aluminum and Vanadium

- High strength-to-weight ratio

- Excellent corrosion resistance

- Good weldability

- Used in aerospace, medical implants, and sports equipment due to its strength, lightweight nature, and biocompatibility.

Grade 9 (Ti-3Al-2.5V):

- Titanium Alloy with Aluminum and Vanadium

- Stronger than Grades 1 and 2, but less strong than Grade 5

- Good corrosion resistance

- Used in aircraft and engine components, as well as applications requiring a balance between strength and corrosion resistance.

Grade 23 (Ti-6Al-4V ELI):

- Titanium Alloy with Aluminum and Vanadium (Extra Low Interstitials)

- Biocompatible and used in medical implants due to its excellent biocompatibility and corrosion resistance.

- Similar properties to Grade 5, with reduced levels of oxygen and iron for enhanced biocompatibility.

Grade 12 (Ti-0.3Mo-0.8Ni):

- Titanium Alloy with Molybdenum and Nickel

- Good corrosion resistance, especially in reducing and mildly oxidizing environments

- Used in chemical processing equipment and marine applications where corrosion resistance is critical.

Grade 7 (Ti-0.15Pd):

- Titanium Alloy with Palladium

- Enhanced corrosion resistance compared to Grades 1 and 2

- Used in chemical and petrochemical industries where resistance to highly corrosive environments is needed.

Grade 29 (Ti-6Al-4V ELI with 0.04-0.08% Palladium):

- Titanium Alloy with Aluminum, Vanadium, and Palladium

- Biocompatible and used in medical implants due to its improved biocompatibility and corrosion resistance.

Titanium Sheet Metal Fabrication Services – Sheet Metal Forming Titanium

At Be-Cu, we understand that exceptional fabrication demands a potent blend of state-of-the-art equipment, technical prowess, and a passion for crafting excellence.Our facility boasts the latest CNC laser cutting machines, waterjet cutters, and press brakes, specifically tailored for handling titanium alloys. These machines are meticulously maintained to ensure the highest level of accuracy and consistency in every project.Be-Cu team comprises seasoned engineers, technicians, and craftsmen who have a deep understanding of titanium’s unique properties and the intricacies of sheet metal fabrication.

Our extensive investment in cutting-edge technology positions us as an industry leader, ready to cater to your diverse titanium sheet metal fabrication needs.Our titanium sheet metal fabrication capabilities cater to a wide array of industries, including aerospace, medical, automotive, and more. Our versatility positions us to serve as your one-stop solution for all your titanium fabrication needs.

Precision fabrication services including titanium alloy. Capable of forming parts from 12 in. to 90 ft. length, 0.015 to 0.125 in. material thickness and +/-0.005 in. tolerance. Large run and low to high volume production runs available. Suitable for conveyor covers, frocking tanks, support panels, trailer walls, railcars, boiler plants, trailers, awnings and flare fences. Serves the aerospace, architectural, construction, marine, military, mining, transportation and power plant industries.

If you need precision titanium sheet metal fabrication, call the experts at Be-Cu today, or email us at [email protected].

Why Use Our Titanium Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal titanium parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication titanium to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off titanium laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom titanium laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

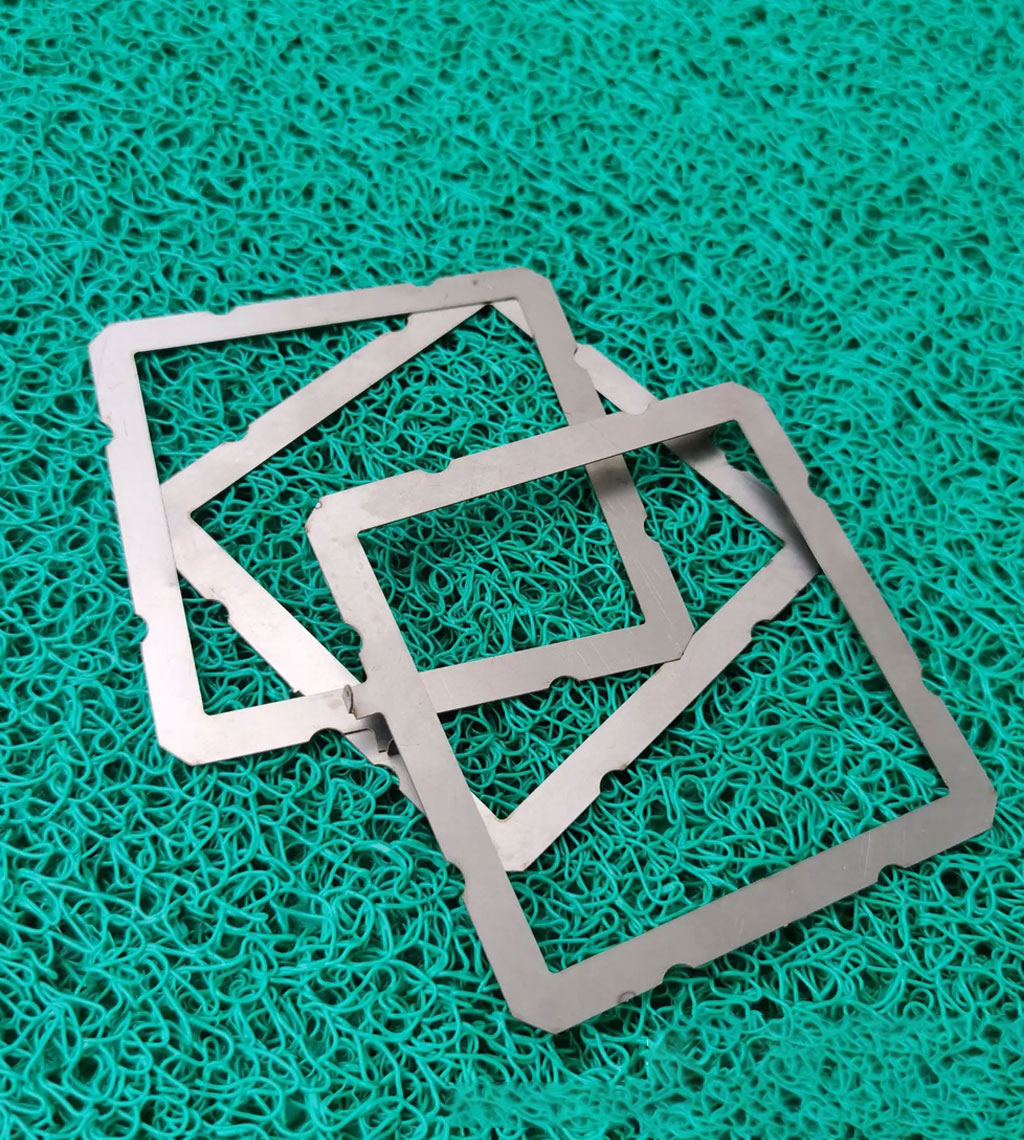

Our Capabilities And Case Studies Gallery Of Titanium Sheet Metal Fabrication

At Be-cu.com, we are highly experienced in manufacturing custom titanium sheet metal parts for demanding applications. By providing a cost-effective fabrication service that doesn’t sacrifice precision or quality, we benefit our customers by making their design ideas for crucial parts and project components become a reality.For more case studies about our services, see the products list below and contact us directly.