Be-Cu : Your One-Stop Shop for Sculpture & Statues 3D Printing Solutions

The progress of the times is always accompanied by the innovation of science and technology. The rapid development of 3D printing technology is a high-tech computer engraving technology, which has been widely used in many fields. In the field of art, 3D printing technology is not uncommon. Some people even predict that 3D printing technology will replace traditional sculpture methods, which may eventually lead to the demise of sculpture art. So much so that some 3D printer manufacturers advertised: “3D printing, everyone is a sculptor”. With the continuous development and application of 3D printing technology, is the training of traditional sculpture modeling ability and techniques still necessary?

The rapid development of 3D printing technology is a technology based on digital model files, using adhesive materials such as cobalt-chromium alloy COCR alloy or photosensitive resin, to construct objects by layer-by-layer printing. It has been widely used in many fields. In the field of art, 3D printing technology is not uncommon.

The advantages of 3D printing sculpture include design freedom, time efficiency, material variety, and the ability to create complex structures. It allows artists to explore intricate and detailed designs that may be challenging or time-consuming to achieve using traditional sculpting methods.Be-Cu prototype company is Custom 3d printing manufacturer of sculpture. Available in different sizes and shapes. Capabilities include 3d printing,cutting, machining, sanding, buffing, and heat treating. Materials worked with are ABS, acetal, acrylic, HDPE, LDPE, polypropylene, polyvinyl chloride, polycarbonate, and PTFE. Design and engineering services are also available.

What Is 3D Printing Sculpture

3D printing sculpture refers to the process of creating sculptures using additive manufacturing technology. Instead of traditional sculpting methods that involve carving or shaping materials by hand, 3D printing allows for the creation of sculptures by layering materials based on a digital 3D model.They serve as artistic expressions, commemorative or memorial monuments, religious or spiritual symbols, historical artifacts, or decorative elements in public spaces, gardens, museums, and private collections.

What Is 3D Printing Statues

3D printing statues refers to the process of using 3D printing technology to create sculptures or statues. It involves the use of additive manufacturing techniques to build up the statue layer by layer based on a digital 3D model.Statues are three-dimensional sculptures representing figures, animals, or objects.

Statues can range in size from small handheld figurines to massive monumental structures.Statues often serve as cultural landmarks, embodying important historical events, ideals, or cultural values.

The technical advantages of 3D printing are obvious, and it can promote the diversified expansion of sculpture art in terms of form, content and materials. Today, with the rapid development of high technology, sculptors should adopt a free and open attitude to introduce this new technology, use it for me, and explore and innovate in a wider field. It is necessary to further expand the field of vision, continuously understand and explore other disciplines and unknown fields, and realize the interaction between the development of 3D printing technology and realistic sculpture art. I believe that in the near future, under the new situation, insisting on the application of art to science and technology, and the perfect integration of 3D printing technology and sculpture art, will definitely bring new changes to sculpture art and expand a new creative space.

3D Printing Sculpture Service – Statues 3D Printing Manufacturer

Be-Cu prototpe is your one-stop shop for comprehensive sculpture and statues 3d printing solutions. Besides 3d printing, we recognize the importance of value-added process in enhancing the appearance and structure properties of Sculpture and Statues. Our specialized choose material process increases the hardness and strength of Sculpture and Statues, thereby improving the durability and performance of the 3d printing Sculpture and Statuess. We meticulously control the temperature and duration of the treatment to match the specific requirements of your application.

Moreover, we also offer a suite of value-added services to ensure your sculpture and statuess are ready for use upon delivery. These services include solution treatment, investment casting,CNC machining, surface treatment options to enhance appearance and corrosion resistance, and assembly services if required.

In conclusion,Be-Cu prototpe ’ expertise in sculpture and statues 3d printing, surface treatment, and other value-added services make us a reliable partner for your art needs. If you have the custom art requirement for sculpture and statues, pls feel free to contact us!

Why Choose Our Sculpture 3D Printing Service?

- Save time and money for your sculpture project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be 3d printing

- Custom complex sculpture 3d printing parts and components at specific tolerances

- High speed 3d printing for prototyping and low to high volume production runs

Certifications & Quality 3D Printing

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for Carbon Fiber customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Quality Solution Of Custom Sculpture and Statues

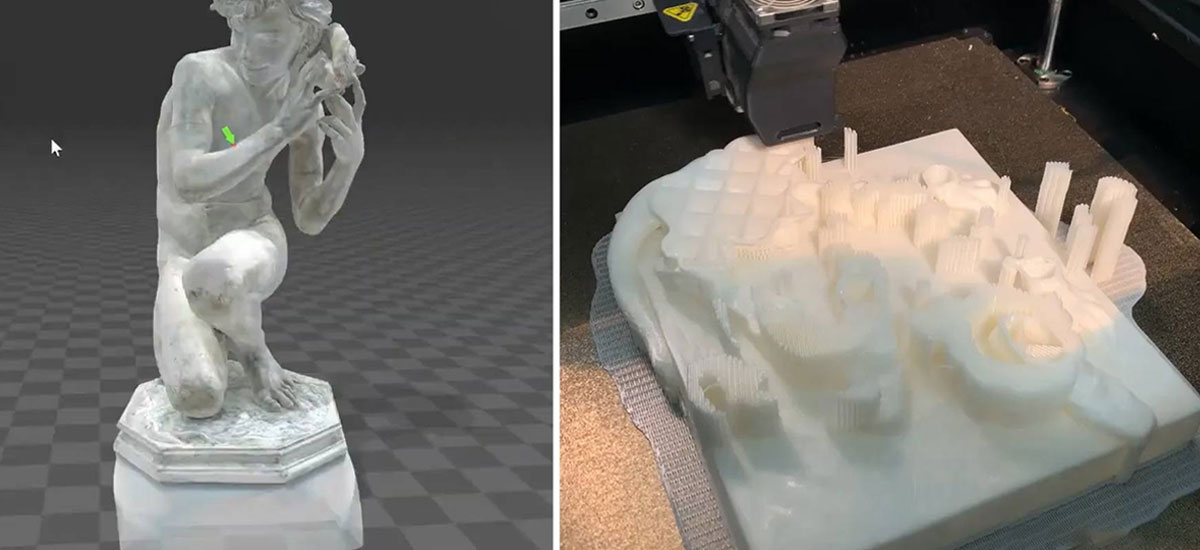

3D Modeling For Sculpture

3D Printing For Sculpture

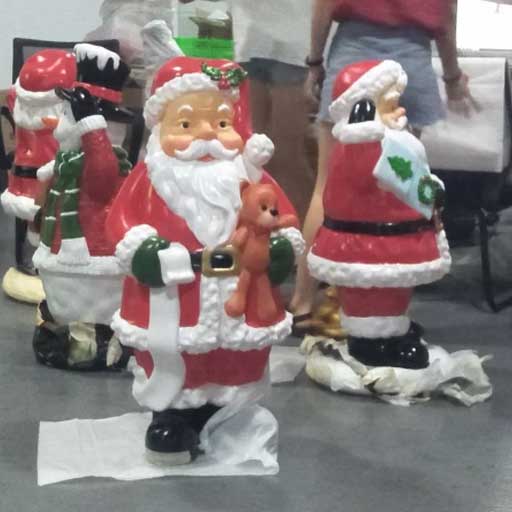

Surface Coloring For Sculpture

1.3D Printing Sculpture Ornaments

Using 3D printing sculpture prototype instead of traditional mud sculpture, for reverse casting, various types of metal crafts can be made with more complete details and higher precision.

2.3D Printing Indoor Large Sculpture

Using 3D printing to make a hollow sculpture prototype, pouring glass fiber reinforced plastic into the interior for reinforcement, then assembling and painting. In this way, the process of opening molds can be omitted, which saves money and time.

2.3D Printing Outdoor Large Sculpture

Use the 3D printing sculpture prototype to replace the traditional mud sculpture and foam sculpture prototype, and perform reverse casting to make fiberglass sculpture, which has a more exquisite effect.

Top China Sculpture And Statues 3D Printing Case Studies

At Be-Cu.com, we aim to be your one-stop source for sculpture and Statues 3D Printing, providing a comprehensive service that covers everything from 3d printing to the final finish. Our technical team comprises industry experts who work closely with every client, understanding their specific requirements and delivering tailored solutions.

The Steps Of 3D Printing Sculpture

- Digital Design: The sculpture starts with a digital 3D model created using computer-aided design (CAD) software or generated from 3D scanning techniques. The digital model defines the shape, form, and details of the sculpture.

- Slicing: The digital model is sliced into multiple thin cross-sectional layers using slicing software. Each layer represents a physical layer that will be printed by the 3D printer.

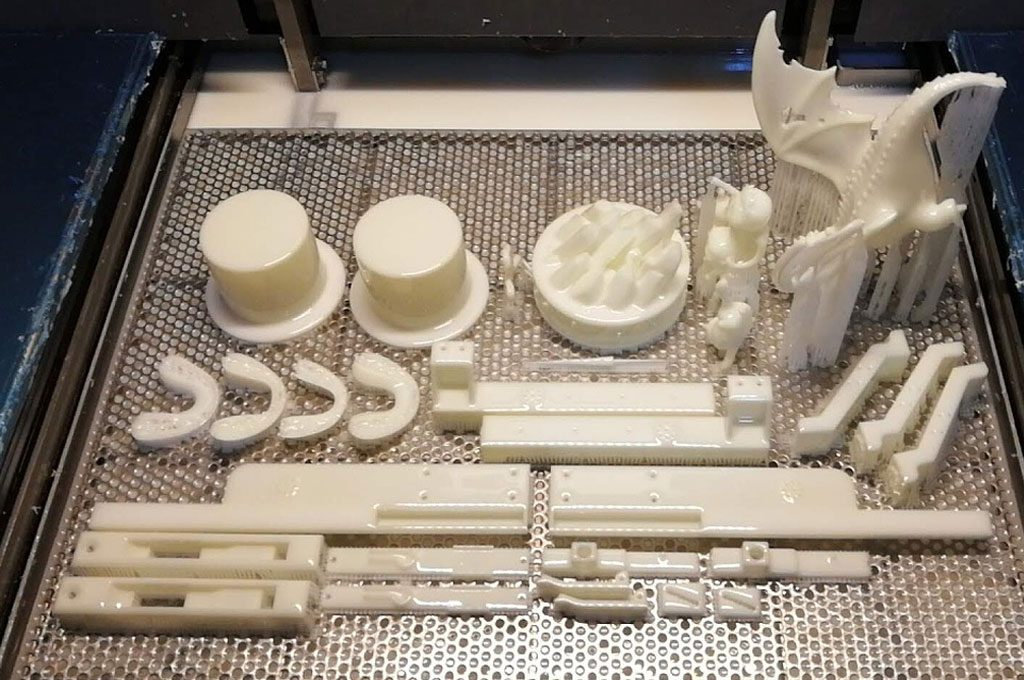

- Material Selection: The appropriate material for 3D printing is selected based on factors such as desired appearance, strength, durability, and ease of use. Common materials used for 3D printing sculptures include various plastics, resins, metals, and composite materials.

- Printing Process: The sliced digital model is sent to a 3D printer, which builds the sculpture layer by layer. The printer deposits or fuses the chosen material based on the instructions provided by the sliced model. This can be done using various techniques such as extrusion, stereolithography (SLA), selective laser sintering (SLS), or binder jetting, depending on the specific 3D printing technology used.

- Post-Processing: Once the 3D printing is complete, post-processing steps may be required to refine the sculpture’s appearance and surface finish. This may involve removing support structures, sanding, polishing, painting, or applying other finishing techniques to achieve the desired final look.

The Advantage Of 3D Printing Sculpture

- Design Freedom: 3D printing allows artists and designers to explore complex and intricate designs that would be difficult to achieve using traditional sculpting techniques. It offers design freedom, enabling the creation of elaborate and detailed sculptures with fine features, intricate patterns, and complex geometries.

- Time Efficiency: 3D printing can significantly reduce the time required to create a sculpture compared to traditional sculpting methods. Once the digital design is ready, the 3D printer can produce the sculpture layer by layer, without the need for manual sculpting or modeling. This can speed up the production process and allow for rapid iteration and experimentation.

- Replication and Scaling: 3D printing enables easy replication and scaling of sculptures. Artists can create a digital model of their sculpture and reproduce it multiple times with consistent accuracy. Additionally, scaling the size of a sculpture is as simple as adjusting the dimensions in the digital model, allowing artists to create different-sized versions of their artwork without the need to start from scratch.

- Material Variety: 3D printing offers a wide range of materials that can be used to create sculptures, including various plastics, resins, metals, and even composite materials. Each material has its own properties and characteristics, providing artists with options to choose the most suitable material for their artistic vision.

- Complex Structures and Internal Features: With 3D printing, artists can create sculptures with complex internal structures and hidden details. The layer-by-layer additive manufacturing process allows for the inclusion of intricate internal features or hollow spaces that are challenging to achieve using traditional sculpting methods.

- Iterative Design Process: 3D printing allows artists to iterate and refine their designs more easily. Artists can quickly create a prototype, evaluate it, make necessary modifications, and print another iteration until they achieve the desired result. This iterative design process helps artists to experiment, explore different possibilities, and refine their artistic vision.

- Preservation and Documentation: 3D printing can be used to create accurate replicas of existing sculptures or historical artifacts for preservation and documentation purposes. This allows for the creation of replicas that can be displayed in museums or used for educational purposes while preserving the original artwork.

- Collaboration and Sharing: 3D printing facilitates collaboration among artists and designers. Digital files can be easily shared, allowing artists to collaborate remotely and work on joint projects. It also enables artists to share their designs with a broader audience, allowing for the dissemination of their work on a global scale.

The 3D Printing Material For Custom Sculpture And Statues

3D printing allows for the creation of sculptures and statues using a variety of materials. The choice of material depends on factors such as the desired appearance, durability, level of detail, and the capabilities of the 3D printing technology used. Here are some commonly used materials for 3D printing sculptures and statues:

- Plastics: Various types of plastics are used in 3D printing. These include polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), polyamide (nylon), and polypropylene (PP). Plastics offer a wide range of colors and can be used to create sculptures with good strength and reasonable detail. However, they may not be as durable or have the same level of detail as some other materials.

- Resins: Resins used in 3D printing, such as photopolymer resins, offer high levels of detail and smooth surface finishes. They can produce sculptures with intricate features and fine textures. Resin materials can vary in properties, including transparency, flexibility, and strength, making them suitable for a range of artistic applications.

- Metals: Metal 3D printing, also known as direct metal laser sintering (DMLS) or selective laser melting (SLM), allows for the production of sculptures in various metals, including stainless steel, titanium, aluminum, bronze, and precious metals like gold or silver. Metal sculptures produced through 3D printing can exhibit excellent strength, durability, and fine detail.

- Composite Materials: Composite materials combine different components, such as a mixture of plastics and metal or ceramic particles. These materials can offer enhanced strength, heat resistance, and unique aesthetic properties. Composite materials enable the creation of sculptures with specific characteristics tailored to the artist’s vision.

- Sandstone: 3D printing technology known as binder jetting can be used to create sculptures using a mixture of sand and a binder material. This results in a solid sandstone-like object that can be further post-processed, textured, or colored. Sandstone offers a unique texture and natural appearance for sculptures.

The availability of materials for 3D printing can vary depending on the specific 3D printing technology and the capabilities of the 3D printer being used. Additionally, the post-processing techniques applied to the printed sculptures, such as sanding, polishing, or painting, can further enhance the appearance and characteristics of the final artwork.

The choice of material for 3D printing sculptures and statues ultimately depends on the artist’s intent, desired aesthetics, and functional requirements. Artists can experiment with different materials and collaborate with 3D printing professionals to select the most suitable material for their artistic vision.

Various Types Of 3D Printing Sculpture And Statues

There are various types of 3D printing technologies used for creating custom sculptures and statues. Each technology has its own characteristics, advantages, and limitations. Here are some commonly used 3D printing technologies for custom sculptures and statues, along with their key differences:

1.FDM 3D Printing or FFF 3D Printing Sculpture

- FDM is one of the most widely used 3D printing technologies.

- It works by extruding thermoplastic filaments layer by layer to build the object.

- FDM offers a wide range of material options, including different types of plastics.

- It is generally more affordable and accessible compared to other 3D printing technologies.

- FDM may not provide the same level of fine detail and smooth surface finish as some other technologies.

2.SLA 3D Printing Sculpture

- SLA uses a liquid photopolymer resin that is solidified by a laser or UV light.

- SLA offers high precision and excellent surface finish, making it suitable for intricate sculptures and detailed features.

- It can produce sculptures with fine details, smooth surfaces, and thin walls.

- However, SLA resin sculptures may require additional post-processing, such as UV curing and cleaning, to achieve the final desired appearance.

3.SLS 3D Printing Sculpture

- SLS involves selectively sintering powdered material (such as plastics or metals) using a high-powered laser.

- SLS allows for the creation of sculptures with good strength, durability, and complex geometries.

- It offers a wide range of material options, including nylon, polycarbonate, and metal powders.

- SLS can produce sculptures with high detail, but the surface finish may be slightly rougher compared to other technologies.

4.DMLS 3D Printing or SLM 3D Printing Sculpture & Statues

- DMLS/SLM uses a high-powered laser to selectively fuse metal powders to create metal sculptures.

- It enables the production of metal sculptures with high strength, durability, and fine detail.

- DMLS/SLM is suitable for creating sculptures in various metals, including stainless steel, titanium, aluminum, and precious metals.

- This technology is commonly used for producing high-quality metal sculptures with intricate features, but it can be more expensive compared to other 3D printing technologies.

5.Binder Jetting For Sculpture & Statues

- Binder jetting involves depositing a binder material onto layers of powdered material to bind them together.

- It can be used with various materials, including sandstone, ceramics, and metals.

- Binder jetting allows for the creation of sculptures with good detail and can be cost-effective for larger-sized sculptures.

- Post-processing steps, such as infiltrating the sculpture with a binding agent or post-curing, may be required to strengthen and enhance the final appearance of the sculpture.

Whether you require a large or small production run,Be-Cu prototype has the expertise and capacity to deliver. Contact us today if you have any inquiry for custom Sculpture stops.

Online Cooperate With Sculpture And Statues 3D Printing Company

Whether you require a large or small production run,Be-Cu prototype has the expertise and capacity to deliver. Contact us today if you have any inquiry for custom Sculpture stops.