3D Printing Wax Pattern For 9 meters Imitation White Jade Dragon Girl Sculpture

In mid-February 2020, Be-Cu received a sculpture order from Vietnam, requesting to complete a 9.8-meter-high imitation white marble dragon girl sculpture by the end of March. After a rough calculation, the time given by the customer is only 40 days!

Be-Cu prototype company has been in the sculpture design and production business for nearly 15 years, but it is the first time that it has received such an urgent large-scale sculpture order. In order to be able to deliver as scheduled, the team of the sculpture factory hastened to start the sculpture design on the one hand, and on the other hand started the technical path planning of the project immediately.

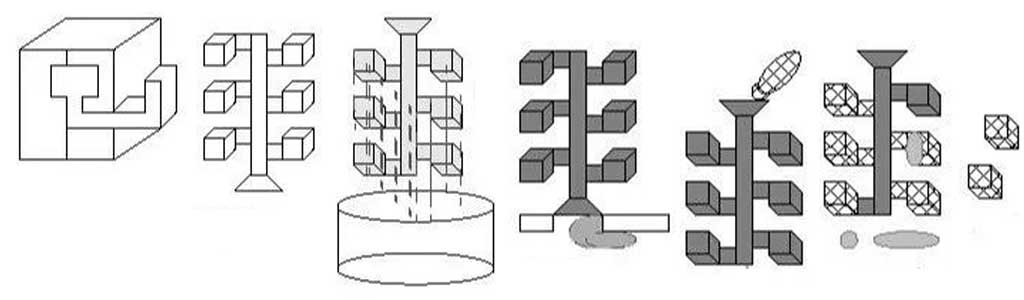

Traditional Large Imitation White Marble Sculpture Production Process

- Make mud drafts of 1:1 equal size;

- Silica sol shells are made on clay manuscripts;

- Use the silica sol shell to turn out pieces of wax molds;

- Casting aluminum blocks;

- Make brackets according to the sculpture design drawings and the structure of the sculpture itself;

- Welding or riveting, welding or riveting the cast parts of split casting on the bracket according to the number;

- Painted and glazed.

- After a series of complicated procedures, the construction period is at least 3 months. This route is obviously not going to work.

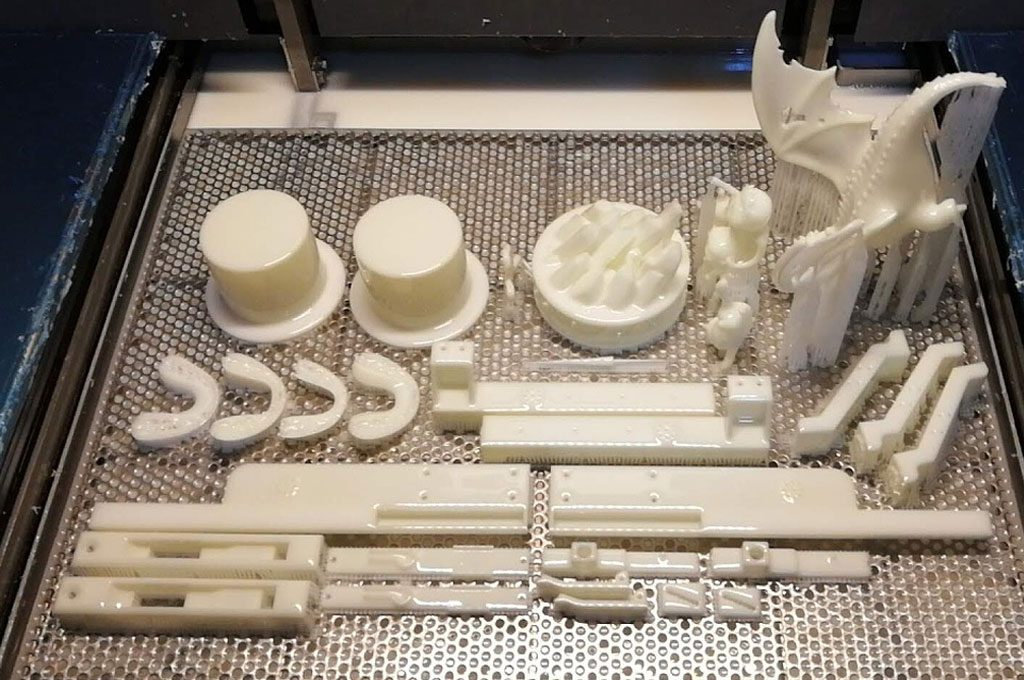

Encountered such a problem, the chief engineer of the sculpture factory did not rush. It turns out that in 2019, in order to improve production efficiency, the sculpture factory specially purchased three 3D printers as new technical equipment. After a period of practice and exploration, it has begun to gradually introduce 3D printing technology into sculpture production, so it has accumulated a lot of success experience.

3D Digital Technology Implementation Steps Of 9.8m Large Dragon Girl Sculpture

Draw a graphic design and ask the customer for preliminary confirmation.

Please ask the art masters from Sichuan Academy of Fine Arts to make small-sized clay drafts according to the plan, and then 3D digitally scan and 3D print to make sculpture samples. Please confirm again with the customer to avoid differences in sculpture shapes.

Why Choose Our Sculpture 3D Printing Service?

- Save time and money for your sculpture project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be 3d printing

- Custom complex sculpture 3d printing parts and components at specific tolerances

- High speed 3d printing for prototyping and low to high volume production runs

Certifications & Quality 3D Printing

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for Carbon Fiber customers

- Skilled in KanBan and CMM Inspection and inventory management systems