Custom 3D Printing For Shoes And Footwear

In recent years, the intersection of technology and fashion has birthed a revolutionary approach to footwear manufacturing – 3D printing. This groundbreaking method offers a paradigm shift from conventional shoe production techniques, introducing unparalleled customization, design flexibility, and sustainability within the industry.

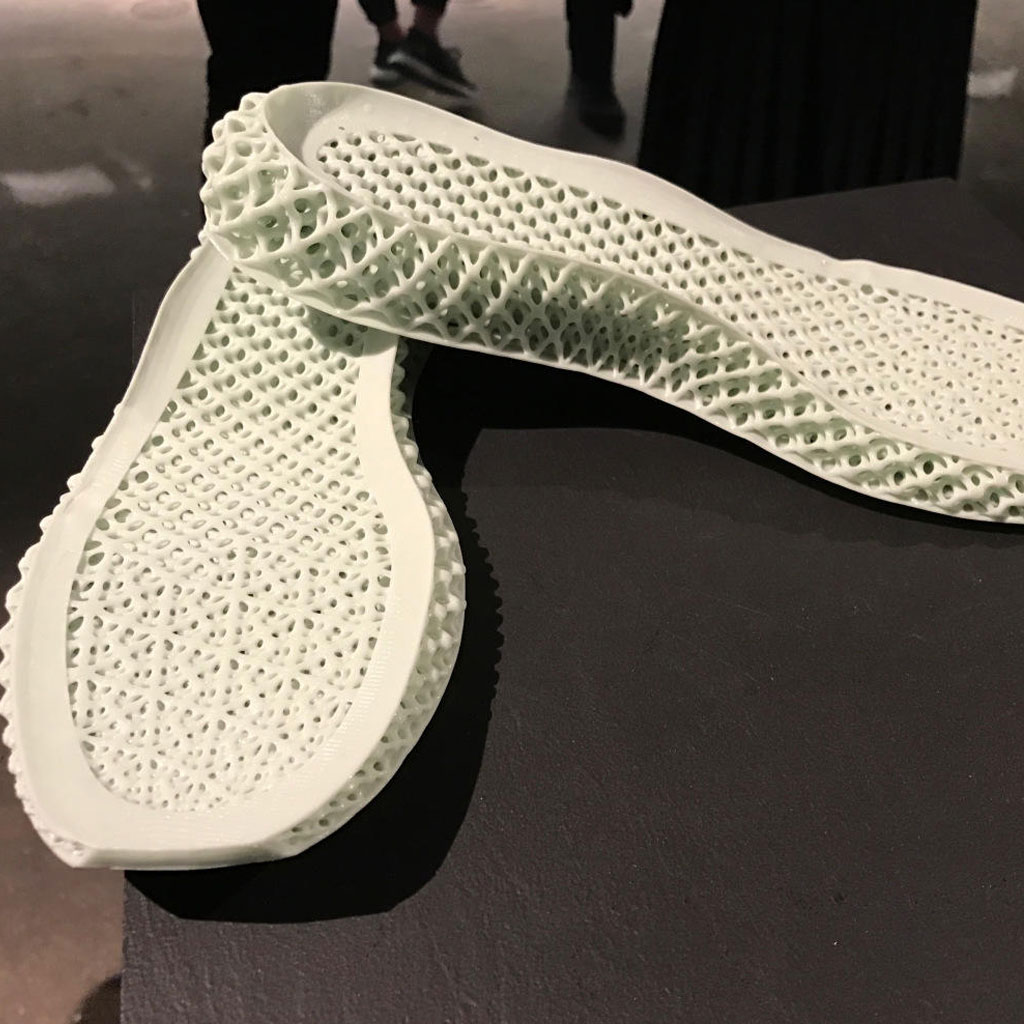

Traditionally, crafting shoes involved labor-intensive processes like cutting, stitching, and molding materials. However, the advent of 3D printing has disrupted this norm by adopting additive manufacturing techniques. This innovative process builds footwear layer by layer based on a digital blueprint or design, allowing for intricate and precise creations.

The Benefit Of 3D Printed Shoes

- Unmatched Customization: Perhaps the most striking feature of 3D printing in footwear is its ability to create customized shoes tailored to an individual’s foot measurements and preferences. This personalization enhances comfort and fit, particularly valuable in athletic and orthopedic footwear.

- Rapid Prototyping: Designers benefit from the swift production of prototypes. This agility facilitates quicker iterations and adjustments in designs before finalizing products for mass production.

- Complex Designs Made Feasible: 3D printing empowers designers to conceive and execute intricate and unconventional shoe designs that might have been impractical or impossible using traditional methods. This flexibility in design opens up a realm of creative possibilities.

- Reduced Material Waste: Unlike traditional manufacturing, where excess materials are often discarded, 3D printing minimizes waste by utilizing only the necessary amount of material for each specific design. This eco-friendly approach aligns with sustainability goals in the industry.

In the dynamic landscape of footwear manufacturing, Shoes 3D printing stands as a disruptive force, revolutionizing the way shoes are conceptualized, designed, and produced. Its potential for customization, design innovation, and sustainable practices heralds a promising future, promising an era where footwear is not just worn but personalized, optimized, and even artfully curated to individual preferences and needs. As technology advances and creativity flourishes, the realm of 3D-printed footwear continues to expand, pushing boundaries and redefining the very essence of modern shoe design and production.

3D Printed Shoes – 3D Printed Footwear Suppliers

BE-CU Prototype is China advance 3d printing manufacturer,we offers 3d printed shoes for your footwear custom needs,Includes metal 3d printing shields worn over shoes for maximum protection to the entire foot-instep as well as toes. Protects against falling, rolling, flying objects or accidental tool blows, designed to withstand impacts of up to 75 pounds. Materials worked with include metals, thermoplastics, polycarbonate, ASA, nylon 3d printing and Ultem® resin. SLS,SLA,Fused deposition modeling (FDM), polyjet and powder bed fusion processes are offered. Offers 0.032 mm layers.

Shoes Prototype 3D Printing

Traditional prototyping methods often entail lengthy processes and manual labor. With 3D printing, creating multiple iterations of shoe prototypes becomes economically feasible. This technology significantly reduces the costs associated with creating molds or tools for each new prototype, making it a cost-effective solution for exploring various design iterations.BE-CU Prototype can achieve unparalleled levels of customization and precision in their shoe prototypes. Whether it’s intricate detailing or specific alterations to fit and comfort, 3D printing allows for minute adjustments and customization tailored to individual preferences or functional requirements.

3D printing allows for experimentation with various materials,we offering insights into their performance, durability, and aesthetic appeal. Designers can test different materials for different parts of the shoe, evaluating their suitability before finalizing the production phase.At our industry-leading Quality Centre of Excellence, equipped with the latest optical CMM equipment, our highly skilled team ensures that every part is delivered right first time, every time. With quality levels approaching Six Sigma standard, we guarantee unmatched levels of repeatability within the 3d printing industry.

Additionally, we follow CAD and CAM drawings and specifications, meaning we can fulfill the requirements of our client’s. Whether a low or high volume order of intricate 3d printing shoes, BECU Prototype has the tools and experience combined to create accurately 3d printing to your needs.

Our Footwear 3D Printing Service for Various Shoes Types

In the dynamic landscape of footwear manufacturing, 3D printing has emerged as a revolutionary force, reshaping the way shoes are designed, produced, and tailored to individual needs. This cutting-edge technology has facilitated the creation of diverse types of shoes across multiple categories, offering customization, innovation, and functionality like never before.

3D Printing Running Shoes

3D Printing Fashion Footwear

3d Printing Sneakers

3D Printing Orthopedic Shoes

3D Printing Casual and Lifestyle Shoes

3D Printing Specialized Footwear

3D Printing Slippers

3D Printing Sandals

The advent of 3D printing in the footwear industry has ushered in an era of unparalleled innovation and customization across various shoe types. From enhancing athletic performance to redefining fashion aesthetics and addressing orthopedic needs, this technology continues to shape the evolution of shoes, promising a future where footwear is not just worn but personalized, optimized, and artistically crafted to meet diverse preferences and requirements.

Case Studies Of Shoes And Footwear 3D Printing

You have a complex shoes design, Our Shoes And Footwear 3D Printing Service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.