What Is 4 Axis CNC Machining

Four-axis machining should precisely be four coordinate axis linkage machining. At present, many CNC systems can achieve such interpolation functions in order to achieve the requirements of multi-face machining in one clamping. There are also some CNC equipment based on the ordinary CNC three coordinate machining centre, the fourth axis is extended to make it possible to meet the multi-face or axis surface trajectory machining.

In CNC machine, the definition of the coordinate system is derived from the right-hand Cartesian right-angle coordinate system, i.e.: the two axes intersecting the origin constitute a planar radial coordinate system, while the three axes intersecting the origin are not co-planar and constitute a spatial radial coordinate system. In the Cartesian system of co-ordinates, three perpendicular axes are made through the fixed point 0, all of which have OO as their origin and generally have the same unit of length. These three axes are called X-axis, Y-axis, Z-axis, collectively referred to as the coordinate axes.

In CNC machine, x, Y, Z-axis positive direction to comply with the right-hand rule, that is, to hold the Z-axis with the right hand, when the four fingers of the right hand from the positive X-axis to the positive Y-axis at an angle of T/2, the thumb pointing is the positive Z-axis, so that the three axes form a space right-angle coordinate system, the point О is called the origin of the coordinates, X, Y, Z-axis is the space of the three linear axes. In addition to the three linear axes in multi-axis machines, three axes of rotation are also defined, which are the A, B and C axes of rotation around the X, Y and Z axes, respectively.

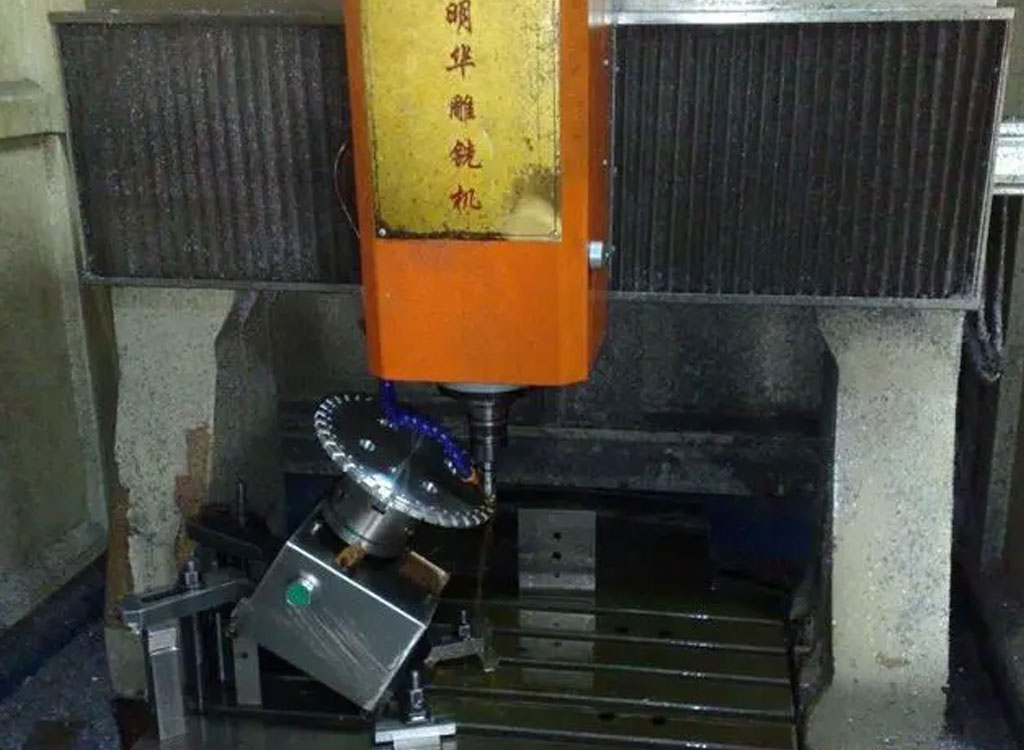

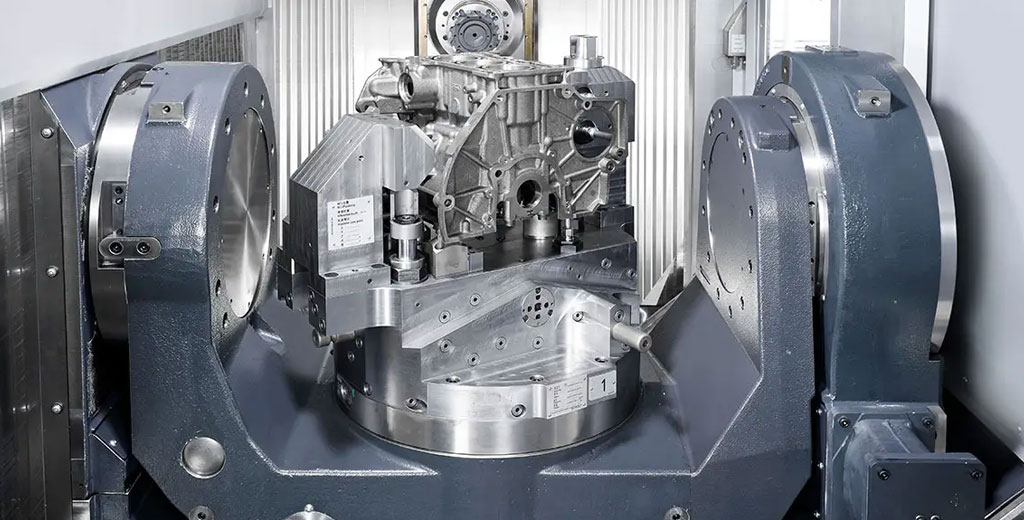

In the heart of CNC machining, four-axis machine are equipped with X, Y, 7 three linear axes and A or B or C three rotary axes of one of the machining centres, and three linear axes and a rotary axis can be interpolated operations and machining, that is, linkage. Vertical machines are often equipped with a fourth axis of A-axis (as shown in Figure 1), while horizontal machines are equipped with a fourth axis of B-axis (i.e. the rotary axis corresponding to the Y-axis).

The Benefits Of 4 Axis CNC Machining

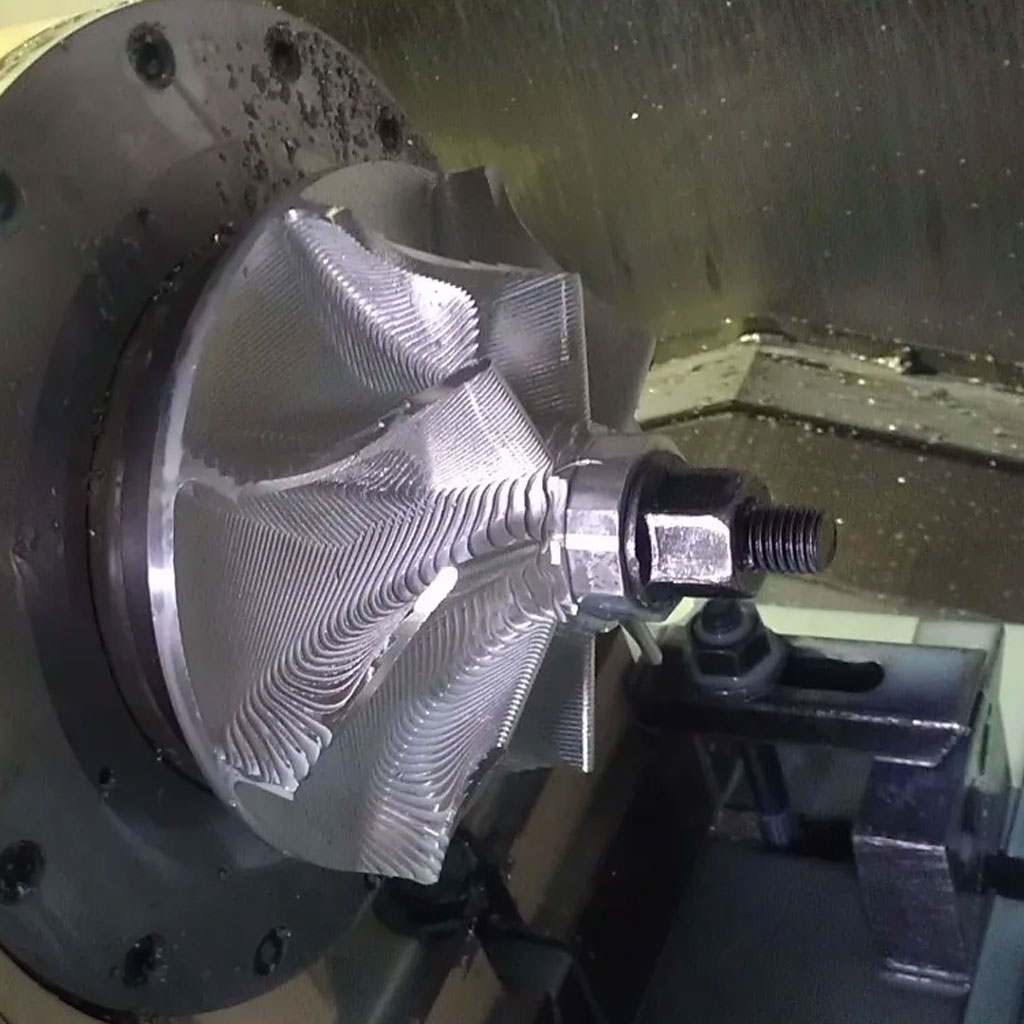

Four-axis machining centres were first used for the machining of curved surfaces, i.e. blades. Nowadays, 4 Axis Machining centres can be used for the machining of polyhedral parts, spirals with rotary angles (cylindrical oil grooves), spiral grooves, cylindrical cams, cycloidal lines, etc. The applications are very wide. From the products processed we can see that four-axis machining has the following characteristics:

- The addition of rotary axes makes the machining of space surfaces possible, greatly improving the accuracy, quality and efficiency of free space surfaces;

- The machining of workpieces that cannot be machined by three-axis machines or that require long clamping lengths (such as long axis machining) can be accomplished by means of a four-axis rotary table;

- Shorten the clamping time, reduce the machining process, as far as possible through a positioning for multi-process machining, reduce positioning errors;

- The tools are greatly improved, extending tool life;

- It facilitates the centralisation of production.

Nowadays, with the deepening of Industry 4.0 and the comprehensive promotion of intelligent manufacturing, multi axis machining centres are being used more and more extensively in manufacturing enterprises as representatives of advanced productivity. Represented by leading manufacturing companies such as aerospace and automotive, the manufacturing process has put forward high requirements due to the complexity of their product structure, the diversity of their components and the extensive use of curved pieces of parts. Traditional machine tools are no longer able to meet such production requirements, and four-, five- and multi-axis machines are the key to solving these problems. In modern manufacturing companies, four- and five-axis machining programming is mostly done using CAD/CAM technology. The use of data models, automatic programming, simulation and post-machining technology allows for the complete virtual machining of complex parts from drawing to finished part, i.e. the “digital twin” mentioned in Industry 4.0. Therefore, knowledge of the basic principles of multi-axis machining and basic programming methods plays an important role in the manufacture of parts and in increasing production efficiency.

The Working Model Of 4 Axis Machining

Four-axis machining centres generally have two machining modes: positioning machining and interpolation machining, which correspond to the machining of polyhedral parts and rotary contouring respectively. The 4 axis CNC machining centre with A-axis as the rotary axis is used as an example to illustrate each of the two machining modes.

The Working Model Of 4 Axis Positioning Machining

When CNC machining polyhedral parts, it is necessary to position the various working planes of the polyhedron so that they are parallel to the A-axis after rotation around the A-axis, otherwise machining will not be possible and under- or over-cutting will occur. Generally, the part is fixed to the rotary table by means of a fixture mounted on the fourth axis, and the datum is calibrated to determine the A-axis zero position of the workpiece coordinate system.

In practice the correct position of the working plane is first obtained by the angular rotation of the A-axis and then locked in place using the relevant command (e.g. M10 in FANUC systems) to ensure that the machined surface is fixed to the A-axis zero position during machining, thus enabling the complete and correct machining of all elements within that machined surface. To machine the next face of the polyhedron, simply open the A-axis using the A-axis open command (e.g. M11 in FANUC systems), then rotate the A-axis until the next machining plane is parallel or perpendicular to the intersection of the A-axis and the spindle axis, and then lock it to machine P.

In this type of machining, the A-axis only plays the role of indexing and is not involved in interpolation, so it does not reflect the operation of the four-axis linkage.

The Working Model Of 4 Axis Interpolation machining

The machining of the axis surface contour of a rotary part or the machining of a spiral groove is typical of interpolation machining calculated using four-axis interpolation. For example, the processing of rotary grooves on cylindrical surfaces and cylindrical cams mainly relies on the rotation of the A-axis plus the movement of the X-axis to achieve. In this case, we need to expand the angle of A-axis and do interpolation with X-axis to ensure the linkage of A-axis and X-axis, and this process will use the cylindrical interpolation command (such as FANUC’s G07.1).

4 Axis Cnc Machining – 4 Axis Machining Services In China

Product Accuracy Is Our Attitude,We offer Volume 4 Axis Cnc Machining services for precision parts. Meet your requirement on price and quality.Where We Build Your precision visions

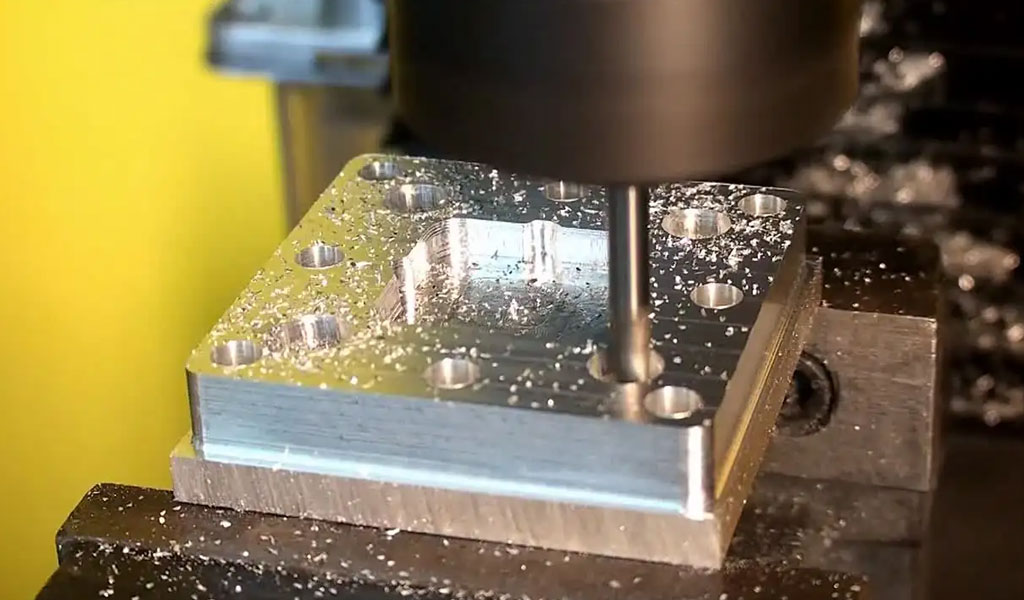

4 Axis Machining is a popular manufacturing process of Precision Machining in which a metal workpiece is eliminated from a metal block when it’s cnc machining. The metal blanking process is often performed with carbide or hardened steel tools. The process is suitable to work with different metals including carbon steel, aluminum, stainless steel and more.

During the 4 Axis Machining operations, the behavior of jig and fixtures (working parts) depends on the yield strength, tensile strength,Structure and thickness of materials. 4 Axis CNC Machining allows producing specialized parts that reduce cost and waste.

If you need mass production for your cnc machining project, Be-cu.com(Pintejin Group)’s 4 Axis CNC Machining technique is a cost-effective solution. We use high-quality machines and tools to avoid cracks and burrs for all precision cnc pieces. Be-cu.com performs different 4 Axis CNC Machining methods for your precision projects. These methods include automatic cnc machining, dfm, jig machining,kanban, and more.

Our Case Studies Gallery Of 4 Axis Cnc Machining Services Parts

We are in the business of creating products that save you time and money. In addition to our 4 Axis Cnc Machining services, we provide laser cutting, sheet metal manufacturing, die casting, and 3d printing. All customers’ orders are inspected by our team to ensure they ship complete with hardware, finish, silk-screening, electronic component assembly, and testing.

Don’t see what you are looking for? Reach out to us and learn how we can work together to create what you need.

-

CNC Machining Bakelite Circuit Board Test Fixture

-

High-Speed Steel (HSS) Die Punching Needles

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

CNC Routing Sunflower Wooden Coaster

-

CNC Custom Wooden Children’s Toys

-

Custom Wood Chess Board, Sets And Pieces

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

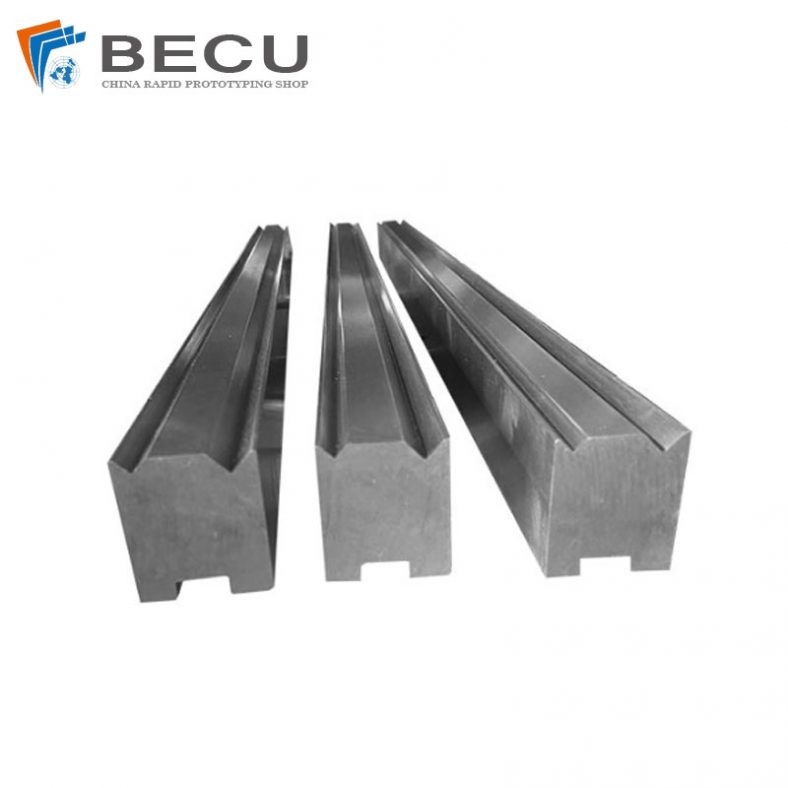

OEM Stainless Steel Press Brake Tooling

-

42CrMo Steel CNC Machining Bender Dies

-

CNC Machining Anti-static Translucent PC Optical Parts

-

4 Axis Machining Highly Transparent Acrylic LED Tunnel Light Lens

-

CNC Turn-Mill Machining Hastelloy c276 Parts