There are few practical articles on threads in the context of design for manufacturing. You will find that most of the articles are about the actual machining of the part and are geared towards the machinist. This article aims to provide a practical guide for engineers designing physical products.

What Is The Thread Made Of?

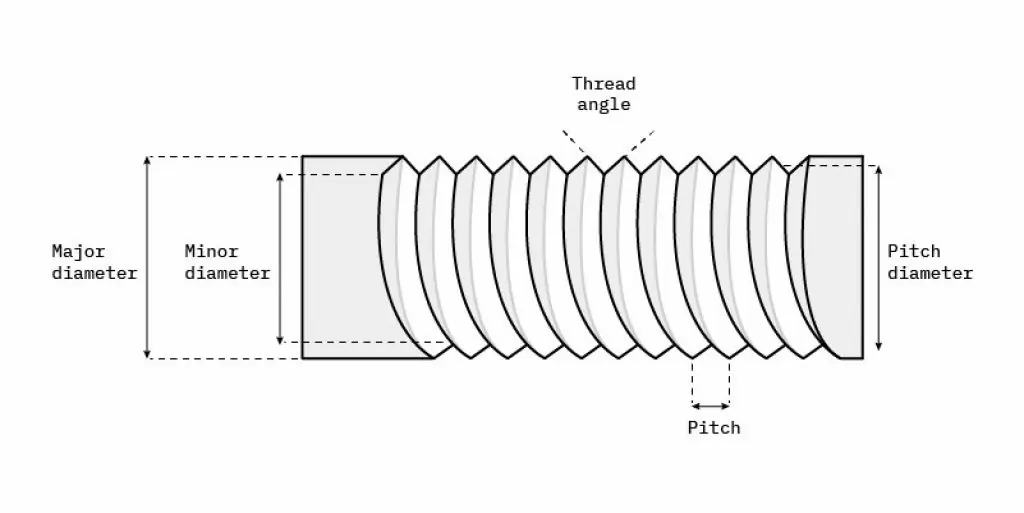

Threads can be either internal or external and usually fit together. By defining the following parameters, it can be displayed (or specified) in technical drawings.

Thread Parameters

- Thread series: Thread profiles (like UN and Metric)

- Thread Type: In the thread family you have different thread types like UNC and UNF for UN, M and MJ for metric.

- Nominal diameter/major diameter/thread size: indicates the thread size, which refers to the major diameter of the thread

- Small diameter: should always be about the same size as the drill bit (hole size)

- Pitch: The distance a point moves linearly (parallel to the axis) in one revolution

- Depth: The depth at which the thread enters the hole

- Tolerance: Allowable tolerance of thread fit

- Class Fit/Tolerance Fit/Tolerance: Define the tolerance range for thread dimensions, including major, minor, and pitch diameters for female or male threaded parts

- Drill Size: Defines the drill size of the thread to be tapped. This is a definition you will see in many thread size tables. It is basically the same size as the small diameter.

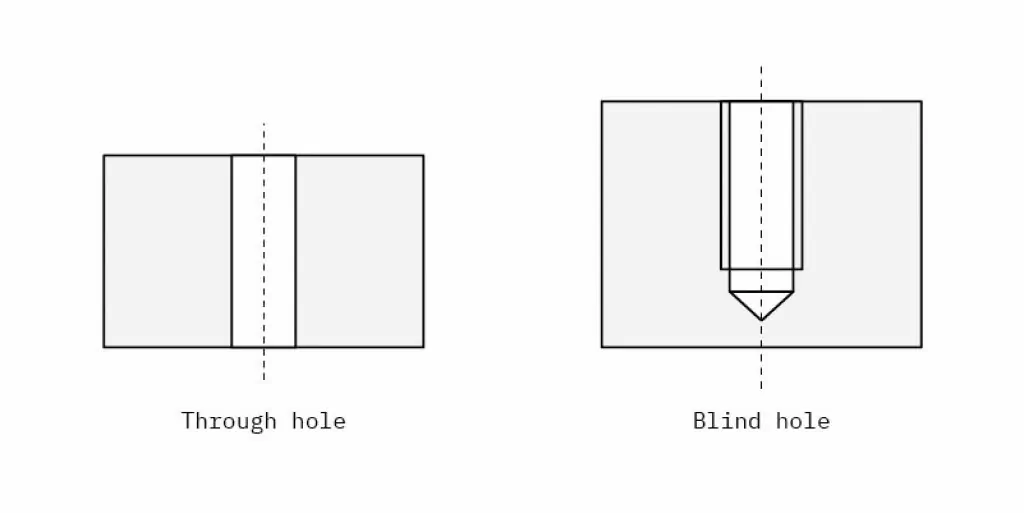

Blind And Through Holes

There are two types of holes in which threads can be defined: blind holes and through holes.

- Through Hole: A hole that runs all the way through the surface. So its depth is the thickness of a particular wall.

- Blind Hole: A hole that does not pass completely through the surface. Therefore, the depth needs to be specified separately.

Overview Of Thread Types

A variety of different thread types are available, the most common being metric and uniform.

Metric thread (M): Metric thread is the metric international standard that follows ISO. This is one of the most common threads.

Unified thread (UNC/UNF/UN/UNEF): Inch standard, usually consisting of coarse (UNC) and fine (UNF) threads. UN is used for a specific set of threads with a uniform or constant number of threads per inch.

Pipe Threads (NPT/NPS/NPTF): Typically used for threaded fittings.

Multi-start thread: A multi-start thread consists of two or more interleaved threads running in parallel with each other.

British Standard Pipe (BSPT): Typically used for threaded fittings.

Thorlabs: Branded thread specifications used to create adapters for Thorlabs’ optical devices.

Trapezoidal thread: a type of trapezoidal thread.

Metric Thread

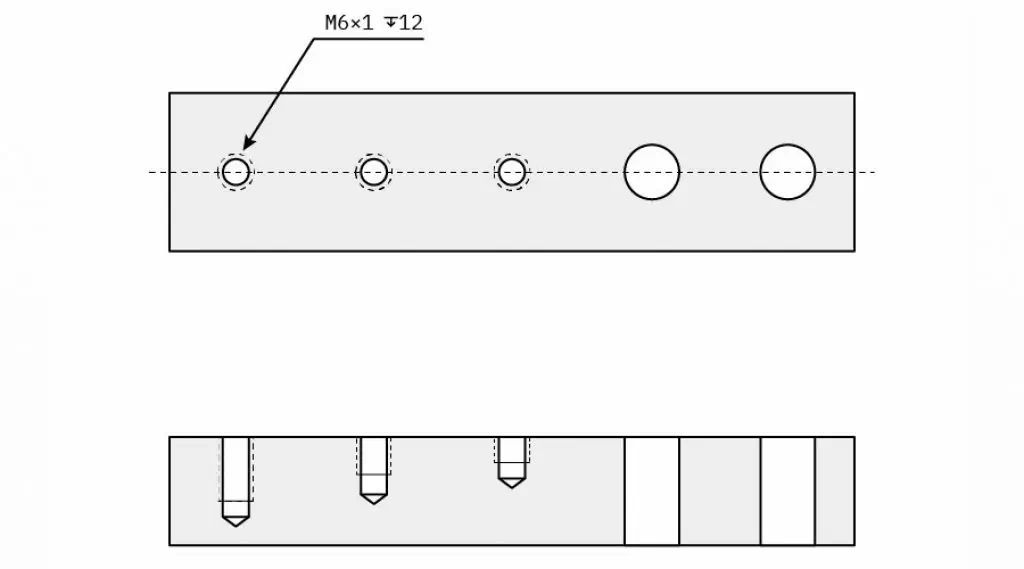

As standard, you can define metric threads by simply entering the type and size (eg M10). As mentioned above, the size is determined by the nominal diameter (major diameter) of the thread. Subsequent pitches and depths will follow common metric common standards (see table below).

All metric threads are assumed to be “thru” on through holes unless otherwise stated. The depth of the blind hole must always be indicated.

Grade Fits – Metric Threads

Grade fits define thread tolerances, and are sometimes called “tolerances” or “thread fits.” Tolerances for internal threads are always written in uppercase letters, while external threads are written in lowercase letters. The standard thread tolerance for female threads is 6H and the standard thread tolerance for female threads is 6g, if you don’t call up any different tolerance in the drawing, the supplier will use that by default. If you’re interested, here’s an in-depth look at why this is.

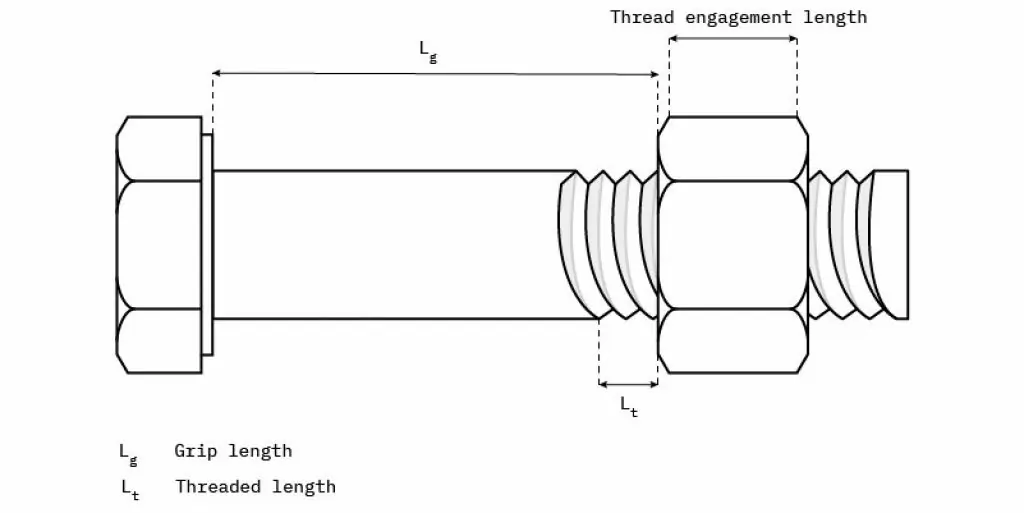

Class fits are generally defined according to ISO 965-1 based on the thread engagement length. The thread engagement length is important to you because it represents the length of the assembly, which is useful for your load bearing calculations.

The default thread engagement length considered is N, representing a typical screw/screw hole connection. Therefore, the class fit defaults to “Medium”, which is 6H (internal thread) and 6g (external thread), as highlighted below.

Recommended Tolerance Classes For Female Threads

| Thread Accuracy | S | N | L |

| High | – | – | – |

| Medium | (5G) | 6G | (7G) |

| Low | – | (7G) | (8G) |

| Thread Accuracy | S | N | L |

| High | 4H | 5H | 6H |

| Medium | 5H | 6H | 7H |

| Low | – | 7H | 8H |

Recommended Tolerance Classes For External Threads

| – | Thread Accuracy | High | Medium | Low |

|---|---|---|---|---|

| Tolerance Position E | S | – | – | – |

| Tolerance Position E | N | – | 6e | (8e) |

| Tolerance Position E | L | – | (7e6e) | (9e8e) |

| Tolerance Position F | S | – | – | – |

| Tolerance Position F | N | – | 6f | – |

| Tolerance Position F | L | – | – | – |

| Tolerance Position G | S | – | (5g6g) | – |

| Tolerance Position G | N | (4g) | 6g | 8g |

| Tolerance Position G | L | (5g4g) | (7g6g) | (9g8g) |

| Tolerance Position H | S | (3h4h) | (5h6h) | – |

| Tolerance Position H | N | 4h | 6h | – |

| Tolerance Position H | L | (5h6h) | (7h6h) | – |

The tolerance position determines the type of tolerance to use. The main ones are g and h.

G (internal) or g (external) tolerance defines the tolerance as a function of pitch diameter

H (internal) or h (external) tolerance defines a static tolerance that does not vary with pitch diameter

Occasionally, you will see that both internal and external threads call a single thread. This represents an assembly fit, for example:

6H/6g

Examples of metric threads in practice:

- Standard ISO thread: M10 x 1.5-6H to LH

- Standard ISO thread: M10

Why Are These Exhalations So Different?

For metric threads, you just make a very simple call, like in the second example, you just indicate the thread series (M) and size (10). In this case, the rest will default to standard. Remember, with blind holes, you must also indicate the depth of the thread, as there is no standard for retraction (see table below).

| Thread Series | Thread Size(Nominal Diameter) | Pitch | Level Match | Depth | Turn Around |

|---|---|---|---|---|---|

| M | 10 | 1.5 | 6H | Pass Through | Left-Hand Thread |

| M | 10 | Unspecified, defaults to the standard pitch of the thread size | Unspecified, defaults to 6H | Not specified, so vias default to thru. For blind vias, the indication is incomplete | Unspecified, so defaults to RH (right hand) |

Uniform Thread

Remember that the fit class defines the tolerance range for the thread size, which is always related to whether the thread is male (B) or female (A). There are 6 types suitable for uniform threads:

Grades 1A and 1B – the loosest tolerances, very rare. Typically used when quick assembly/disassembly is required.

Class 2A and Class 2B – “Medium” tolerance, this is the most common fit. This is the best choice for balancing thread performance and convenience.

Class 3A and 3B – very tight tolerances. Used when the thread is critical to the safety of the end product service.

If no fit is indicated, the default fit class is 2A for female threads and 2B for male threads.

Design Skills

1) Keep it universal

One thing that will definitely save you time and money when it comes to manufacturing is keeping things generic.

It is only through trial and error that experienced engineers realize the importance of keeping components as generic as possible—even when designing custom products. If there is an existing solution, don’t complicate it. This also applies to threads, always choose as many threads and sizes as possible from the usual series.

Universal Series: UN (i.e. UNC and UNF) and Metric (i.e. M)

Common sizes: UN list, metric list

2) Pay Attention To The Size Of The Hole

When we make parts that contain threads, one of the most common mistakes we see is that the thread size doesn’t seem to match the hole size they call it.

This is a problem because it can lead to confusion if the thread size is correct, if the hole is the wrong diameter, or vice versa. As a manufacturer, we cannot make assumptions that this confusion causes delays in manufacturing time (at least 1-2 days).

3) Mark The Blind Hole Thread Depth

Another reason for the delay is the incomplete thread specification.

Blind holes are holes that do not pass through the entire wall thickness of the part. If you draw a line on a blind hole, you must indicate the depth of the line.