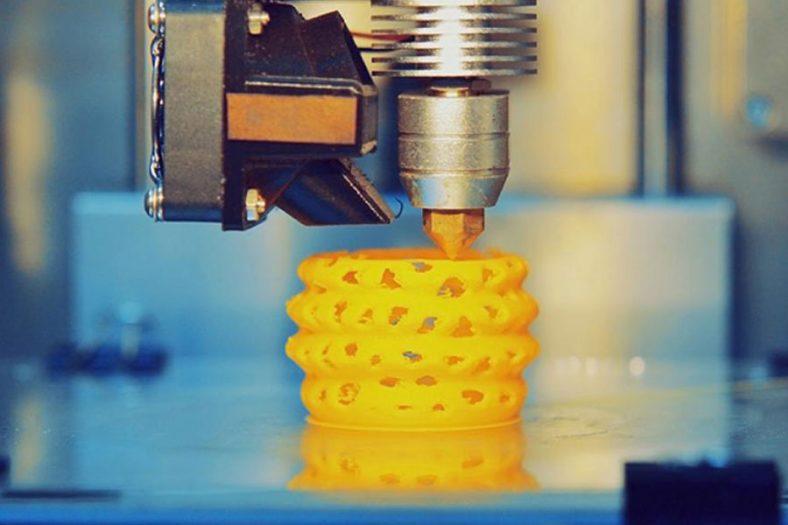

Buildbed adhesives play a crucial role in the 3D printing process, ensuring proper adhesion between the 3D printed object and the build platform. Achieving excellent adhesion is essential to avoid print failures, warping, and other common printing issues. As the 3D printing industry continues to expand, a wide range of buildbed adhesives has emerged, each tailored to specific materials and printing conditions. This comprehensive guide explores the importance of buildbed adhesives, their types, application methods, troubleshooting techniques, and best practices to enhance printing success.

The Significance of Buildbed Adhesives in 3D Printing

Buildbed adhesives play a critical role in the 3D printing process, serving as the bonding agent between the 3D printed object and the build platform. Proper adhesion is essential for achieving successful prints and preventing common issues such as warping, lifting, or misalignment. The significance of buildbed adhesives in 3D printing can be understood through the following key points:

- Ensuring Proper Adhesion: One of the primary functions of buildbed adhesives is to ensure that the first layer of the 3D printed object adheres securely to the build platform. This initial layer serves as the foundation for the rest of the print, and if it does not adhere properly, the entire print may fail.

- Preventing Warping and Lifting: Warping and lifting occur when the printed object cools at an uneven rate, causing the edges to lift away from the build platform. Buildbed adhesives create a strong bond between the printed object and the platform, reducing the likelihood of warping and lifting during the printing process.

- Minimizing Print Failures: In 3D printing, print failures can be frustrating and wasteful. Without adequate adhesion, prints may detach from the build platform, leading to misaligned layers or incomplete prints. Buildbed adhesives help reduce the risk of print failures, ensuring a higher success rate in the printing process.

- Enhancing Print Quality: Proper adhesion is essential for achieving high-quality 3D prints. A strong bond between the build platform and the printed object allows for accurate layering, resulting in smoother surfaces and improved overall print quality.

- Supporting Various Print Materials: Different 3D print materials have varying adhesion requirements. Some materials, like PLA, adhere well to a clean build platform, while others, like ABS, may require additional adhesion aids. Buildbed adhesives are tailored to accommodate the unique properties of each material, providing optimal adhesion for a wide range of print materials.

- Enabling Large Prints and Overhangs: For larger prints or prints with significant overhangs, buildbed adhesives offer crucial support during the printing process. They help keep the print stable and prevent it from detaching from the platform, even as the print progresses to higher layers.

- Ease of Print Removal: While buildbed adhesives ensure strong adhesion during printing, they also facilitate easy removal of the printed object once the printing is complete. Properly selected adhesives strike a balance between strong adhesion during printing and ease of part removal without damaging the build platform or the printed object.

- Time and Cost Savings: By promoting successful prints and reducing print failures, buildbed adhesives help save both time and material costs. Fewer failed prints mean less wasted time and fewer resources spent on reprints.

- Optimizing Print Settings: Proper buildbed adhesion can also help optimize print settings such as bed temperature and nozzle height. When the first layer adheres correctly, it allows for more precise adjustments in the printer settings to achieve the desired print quality.

Buildbed adhesives are essential in the 3D printing process, ensuring proper adhesion between the printed object and the build platform. By preventing warping, minimizing print failures, supporting various print materials, and optimizing print quality, buildbed adhesives contribute significantly to the success and efficiency of 3D printing. As the 3D printing industry continues to advance, the development of specialized adhesives tailored to specific materials and applications will further enhance the overall printing experience, enabling users to create high-quality, functional, and aesthetically pleasing 3D printed objects.

Types of Buildbed Adhesives

There are various types of buildbed adhesives available, each designed to cater to specific 3D printing materials and printing conditions. The choice of buildbed adhesive depends on factors such as the build material, print temperature, build platform material, and desired adhesion strength. Let’s explore some common types of buildbed adhesives used in 3D printing:

BuildTak and Kapton Tape

BuildTak is a popular buildbed adhesive material known for its durable and heat-resistant surface. It is a specialized sheet that adheres to the build platform, providing excellent adhesion for a wide range of 3D printing materials, including PLA, ABS, PETG, and more. Kapton tape, a polyimide film tape, is another option for adhesion on heated build platforms, especially for high-temperature materials like ABS.

Glue Sticks and Glue Solutions

Glue sticks are commonly used as buildbed adhesives for materials like PLA and PETG. Applying a thin layer of glue stick to the build platform helps improve adhesion, especially on non-heated platforms. Glue solutions, which are typically water-based, can also be used for adhesion on both heated and non-heated build platforms.

ABS Juice and Acetone Solutions

ABS juice is a mixture of ABS filament and acetone, forming a sticky adhesive solution used to enhance adhesion for printing with ABS. The mixture can be brushed onto the build platform or applied using a felt pad, providing strong adhesion for ABS prints.

3D Printer Adhesive Sprays

There are adhesive sprays specifically formulated for 3D printing, such as 3D printer bed adhesion sprays. These sprays create a thin adhesive layer on the build platform, offering a strong bond for various materials.

Specialized Buildbed Adhesives for Specific Materials

Some buildbed adhesives are designed specifically for certain materials or applications. For example, there are adhesives tailored for printing with flexible materials like TPU, which require unique adhesion properties. Other specialized adhesives may cater to composite materials or those with specific surface properties.

PVA Glue

Polyvinyl acetate (PVA) glue, commonly known as white school glue, can be used as a buildbed adhesive for certain materials like PLA. Diluted PVA glue can create an adhesive surface on the build platform, providing good adhesion for PLA prints.

Hair Spray

Some 3D printing enthusiasts use hairspray as a buildbed adhesive, especially for materials like PLA. A light mist of hairspray on the build platform helps improve adhesion and is particularly effective on non-heated build surfaces.

Specialized Magnetic Build Surfaces

Magnetic build surfaces with specialized adhesive properties have gained popularity in recent years. These flexible build surfaces allow for easy removal of printed objects by flexing the surface, releasing the adhesive grip.

The effectiveness of a buildbed adhesive may vary depending on the specific 3D printer, build platform material, and the print material being used. Additionally, some 3D printers come with their proprietary buildbed adhesion solutions designed to work optimally with the printer’s specifications.

Ultimately, the selection of the appropriate buildbed adhesive is crucial to achieving successful prints and preventing common issues like warping, lifting, and misalignment. Experimentation and finding the right balance between adhesion and ease of part removal are essential for a positive 3D printing experience.

Optimizing Buildbed Adhesives for Different Print Materials

Optimizing buildbed adhesives for different print materials is crucial to achieving successful 3D prints. Each material has unique adhesion requirements, and selecting the right buildbed adhesive and application technique can significantly impact print quality and reduce print failures. Here are some tips and recommendations for optimizing buildbed adhesives for different print materials:

PLA (Polylactic Acid) Printing

Buildbed Adhesive: For PLA prints, BuildTak, Kapton tape, or glue sticks are effective choices. Many 3D printers come with a heated bed that provides sufficient adhesion for PLA without the need for additional adhesives. However, if using a non-heated bed, a thin layer of glue stick or a specialized buildbed adhesive spray can improve adhesion.

Application: Apply the adhesive in a thin and even layer. If using glue stick, spread it evenly across the build platform. For adhesive sprays, follow the manufacturer’s instructions and avoid excessive application.

ABS (Acrylonitrile Butadiene Styrene) Printing

Buildbed Adhesive: ABS prints often benefit from ABS juice, a mixture of ABS filament and acetone. Alternatively, BuildTak, Kapton tape, or specialized buildbed adhesives can also be used.

Application: Apply ABS juice using a felt pad or brush, creating a thin and uniform layer. For other adhesives, ensure an even and light application to prevent over-adhesion.

PETG (Polyethylene Terephthalate Glycol) Printing

Buildbed Adhesive: For PETG prints, BuildTak or specialized adhesives are commonly used. Glue sticks can also work, but adhesion may not be as strong as with other materials.

Application: Apply the adhesive sparingly and evenly to prevent over-adhesion. Too much adhesive may make part removal challenging.

Nylon Printing

Buildbed Adhesive: Nylon often benefits from specialized buildbed adhesives designed for high-temperature materials. PVA glue can also be used for adhesion.

Application: Apply the adhesive in a thin and uniform layer. Nylon tends to warp, so proper bed leveling and adhesion are essential.

Specialty Materials (TPU, PVA, etc.)

Buildbed Adhesive: Specialty materials like TPU (flexible filament) and PVA (water-soluble support material) may require specific buildbed adhesives or surface treatments.

Application: Follow the manufacturer’s recommendations for the appropriate buildbed adhesive or surface preparation. Specialty materials often have unique adhesion requirements.

Heated Bed vs. Non-Heated Bed

Some materials, like PLA and PETG, adhere well to a heated bed, while others, like ABS, may require a heated bed to reduce warping. Consider using specialized buildbed adhesives or adhesive aids for non-heated beds to improve adhesion.

Bed Leveling and Z-Offset

Proper bed leveling and Z-offset (the distance between the nozzle and build platform) are essential for achieving good adhesion. Ensure that the first layer adheres firmly to the build platform without being squished too much or too little.

Post-Printing Techniques:

Once the print is complete, allow the build platform to cool down before attempting to remove the printed object. Using a gentle twisting motion can help release the printed object without damaging the build surface.

Experimentation and Calibration:

Optimizing buildbed adhesives may require some experimentation and calibration. Test different adhesives and application techniques to find the best combination for each material and specific print conditions.

Optimizing buildbed adhesives for different print materials is essential for achieving successful and high-quality 3D prints. Understanding the unique adhesion requirements of each material and using the appropriate buildbed adhesive and application technique will help prevent common printing issues and ensure a positive 3D printing experience. Regularly calibrate and fine-tune the printing settings to optimize adhesion and achieve the best results with different materials.

Problems Removing Prints

Removing 3D prints from the build platform can sometimes be challenging, especially if the buildbed adhesion is strong. However, there are various techniques and tips to make print removal easier and avoid damaging the print or the build surface. Let’s explore common problems encountered when removing prints and how to address them:

Adhesion Too Strong

If the print is firmly adhered to the build platform, try letting the platform cool down completely. As the platform cools, the print material may contract slightly, making it easier to release.

Use a thin, flexible spatula or a 3D print removal tool to gently pry the print from the platform. Avoid using excessive force, as it may damage both the print and the build surface.

Prints Stuck to Heated Build Platform

For prints that stick too well to a heated build platform, try turning off the heat and allowing the platform to cool down before attempting to remove the print.

Consider using a buildbed adhesive or a specific print removal tool designed for heated beds to avoid damaging the platform.

Warping or Lifting During Removal

Warping or lifting during print removal can happen if the build platform is not leveled correctly or if the print was not adhered uniformly.

Ensure proper bed leveling and calibration to prevent warping or lifting during printing and make print removal smoother.

Prints Breaking or Cracking

Delicate or intricate prints may be prone to breaking or cracking during removal. Use a soft, flexible spatula or a print removal tool to minimize stress on the print.

Consider printing with thicker walls or adding a brim or raft to increase the stability of the print during removal.

Prints Sticking to BuildTak, Kapton Tape, or Other Adhesive Surfaces

If the print is sticking too well to BuildTak, Kapton tape, or other adhesive surfaces, try using a release agent, such as rubbing alcohol or adhesive remover, to loosen the bond before attempting to remove the print.

If the print consistently sticks too well to the adhesive surface, consider trying a different buildbed adhesive more suitable for the print material.

Excess Buildbed Adhesive Residue on the Print

If there is excessive buildbed adhesive residue on the print, use rubbing alcohol or warm soapy water to clean it off. A soft brush can help remove stubborn residue gently.

Avoiding Damage to Build Surface

To avoid damaging the build surface, use appropriate tools specifically designed for print removal, such as a print removal tool, scraper, or spatula.

If using a magnetic or flexible build surface, flex it gently to release the print, taking care not to damage the surface.

Preventive Measures

Applying a thin layer of buildbed adhesive and ensuring proper bed leveling can help prevent prints from sticking too strongly to the build platform.

Using a raft or brim during the printing process can also improve print adhesion and make removal easier.

Removing 3D prints from the build platform can be made easier by using the right techniques and tools while ensuring proper bed leveling and calibration. Preventive measures such as using the appropriate buildbed adhesive and adjusting print settings can also contribute to successful print removal. By following these tips and troubleshooting techniques, 3D printing enthusiasts can improve the print removal process and enjoy a more seamless and efficient 3D printing experience.

Buildbed adhesives are fundamental to successful 3D printing, providing the necessary bond between the printed object and the build platform. As the 3D printing industry continues to grow and evolve, so too do the options for buildbed adhesives, catering to a wide range of materials and printing conditions.

By understanding the significance of proper adhesion, exploring the different types of buildbed adhesives, mastering application techniques, troubleshooting common adhesion issues, and adopting best practices, 3D printing enthusiasts can achieve consistent and reliable results in their printing endeavors.

Moreover, with a growing emphasis on eco-friendly and sustainable practices, the development of biodegradable and water-based buildbed adhesives aligns with the broader goals of minimizing environmental impact.

Looking ahead, ongoing research and innovation in the realm of buildbed adhesives promise exciting advancements, including nanotechnology-enhanced solutions and smart coatings. These developments will undoubtedly contribute to further optimizing the 3D printing process and making it even more accessible and efficient for users across various industries.

In conclusion, understanding the nuances of buildbed adhesives empowers 3D printing enthusiasts to unlock the full potential of their printers and unleash their creativity in manufacturing high-quality, functional, and visually appealing 3D printed objects. As the 3D printing landscape continues to evolve, buildbed adhesives will remain an indispensable element for successful printing experiences and continued growth in the realm of additive manufacturing.

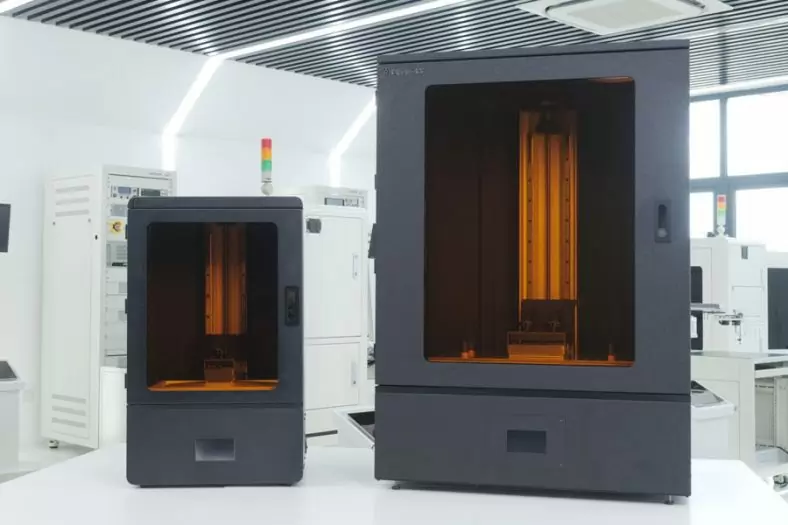

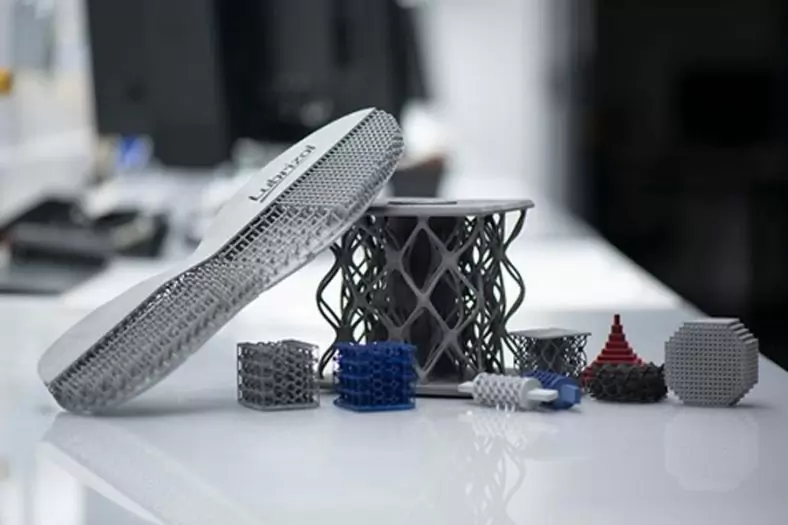

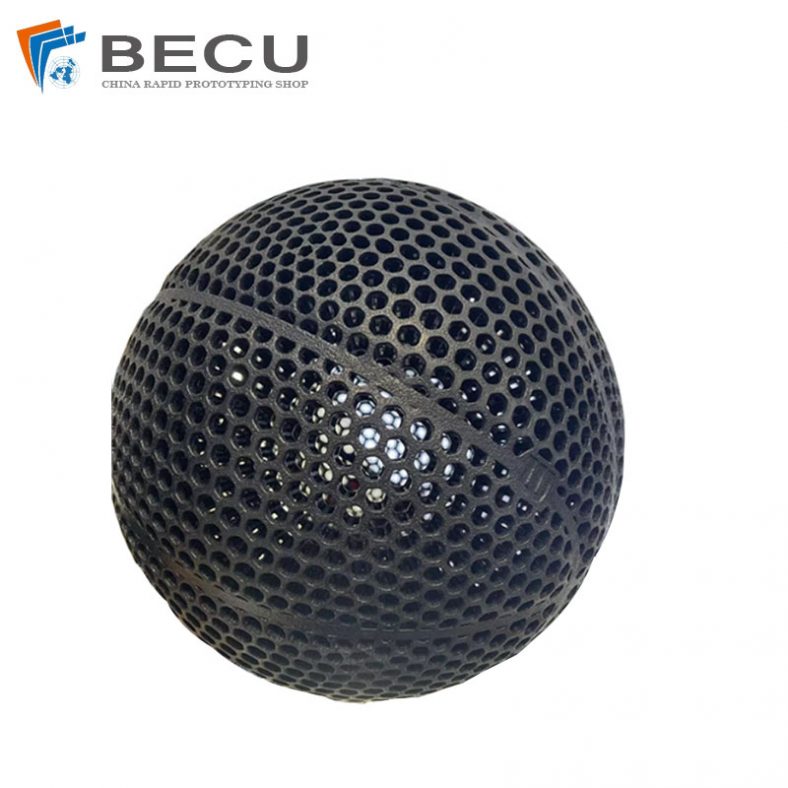

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.