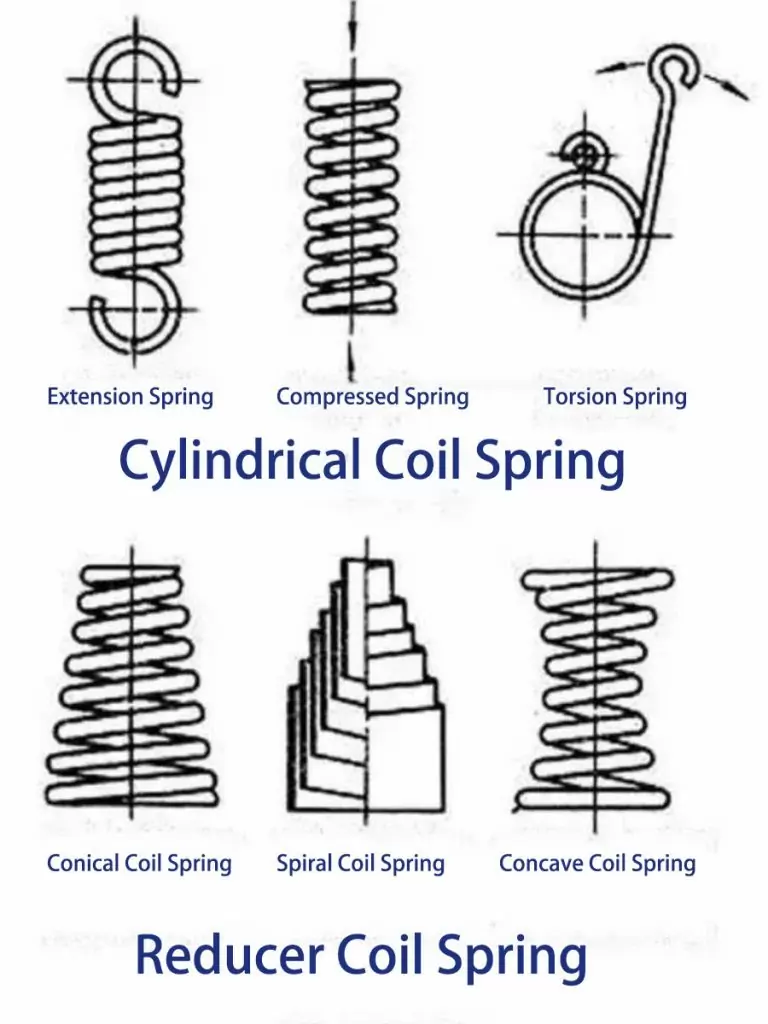

The Classification Of Springs

According to the nature of the force, springs are divided into: extension springs, compression springs, torsion springs and bending springs.

The spring is an elastic element widely used in the mechanical and electronic industries. The spring can produce a large elastic deformation when it is loaded, and convert the mechanical work or kinetic energy into deformation energy. After unloading, the deformation of the spring disappears and returns to original state, while transforming deformation energy into mechanical work or kinetic energy. The ratio of the load to the deformation of the spring is called the spring stiffness, and the higher the stiffness, the stiffer the spring.

The Role Of The Spring

- Cushioning and vibration reduction. Such as the shock-absorbing spring under the car and train box, the buffer spring of various buffers, etc.;

- Control the movement of the mechanism. Such as valve springs in internal combustion engines, control springs in clutches, etc.;

- Store and output energy. Such as clock springs, bolt springs, etc.;

- Measure the magnitude of the force. Such as spring balances, springs in dynamometers, etc.;

Spring Material And Allowable Stress

Springs are often subjected to alternating and impact loads during work, and require large deformations, so the spring material should have high tensile strength, elastic limit and fatigue strength. In the process, there must be a certain hardenability, not easy to decarburize, and the surface quality is good.

| Material | Material | Allowable Shear Stress [t]MP | [t]MP | [t]MP | Shear Elastic Modulus Quantity G/MPa | Recommended Temperature/c |

|---|---|---|---|---|---|---|

| Carbon spring wire | Ⅰ、Ⅱ、Ⅱ、Ⅲ Group | 0.8s | 0.4s, | 0.5s. | 80000 | -40~120 |

| Carbon spring wire | 65Mn | 420 | 560 | 700 | 80000 | -40~120 |

| Alloy spring wire | 60Si2Mn | 480 | 640 | 800 | 80000 | -40~200 |

| Alloy spring wire | 65SiMnA | 570 | 760 | 950 | 80000 | -40250 |

| Alloy spring wire | 5OCrVA | 450 | 800 | 750 | 80000 | -40~210 |

| Stainless steel wire | 1Cr18Hi9 | 330 | 440 | 550 | 73000 | -250~300 |

| Stainless steel wire | 4Cr13 | 450 | 600 | 750 | 77000 | -40~300 |

Note:

- According to the number of cycles under load, springs are divided into three categories: Category I > 10′; Category II = 10~10 and impact load; Category II N<103.

- The allowable stress of the hook-and-loop tension spring is 80% of the value in the table; if the urn is subjected to strong pressure treatment, the allowable stress of the value in the table can be increased by 20%

- According to different mechanical properties, carbon spring steel is divided into four groups, of which group I has the highest tensile strength, group I is the second, and group 1 is the lowest. I. Group has the same tensile strength as Group I, but has better plasticity.

The manufacture Of Springs

The manufacturing process of the coil spring includes: rolling, making of hooks or finishing of face rings, heat treatment and process performance test.

For mass production, it is rolled on a universal automatic spring coiling machine; for single-piece and small batch production, it is made on an ordinary lathe or by hand. When the diameter of the spring wire is less than or equal to 8mm, the cold rolling method is commonly used, heat treatment is required before rolling, and low temperature tempering is required after rolling. When the diameter is greater than 8mm, the method of hot coiling (hot coil temperature 800℃~1000℃) is adopted. After hot coiling, it is quenched and tempered at medium temperature. After the spring is formed, the surface quality inspection shall be carried out. and other defects; springs subject to variable loads must also undergo surface treatment such as shot peening to improve spring fatigue life.

Stress Calculation Of Spring

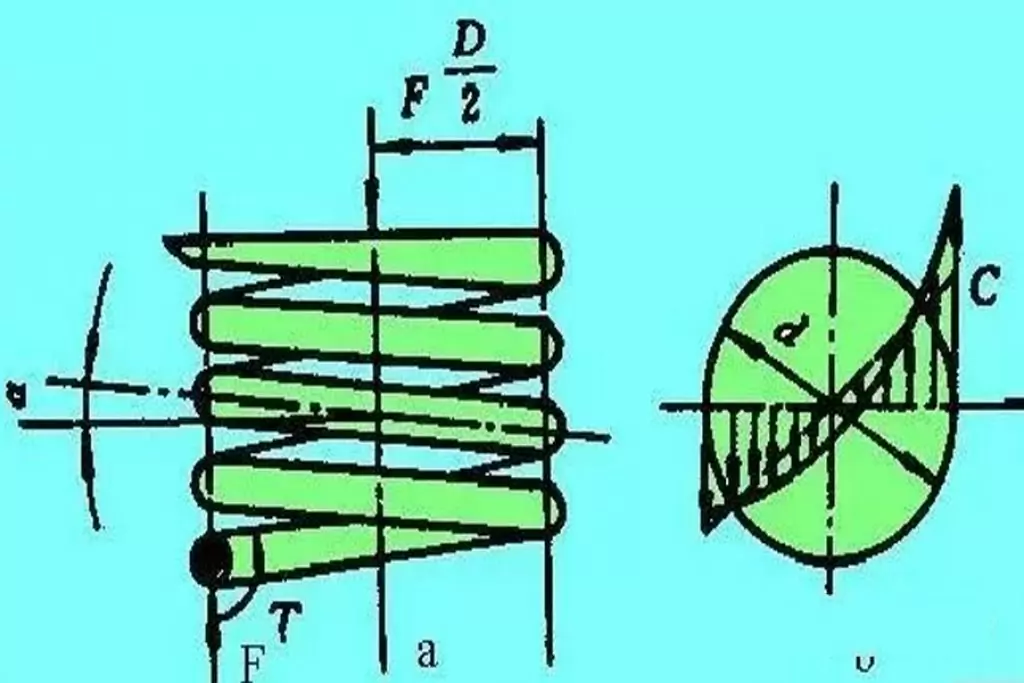

▲Analysis of the force of the compression spring

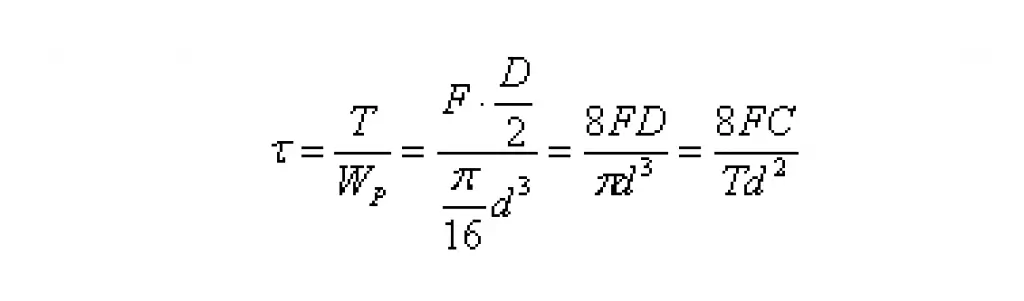

Figure (a) is a cylindrical helical compression spring, which is subjected to an axial working load F. According to the analysis of the section method, it is known that the spring wire section is subjected to the shear force F and the torque T=FD/2, and the shear stress caused by the torque is:

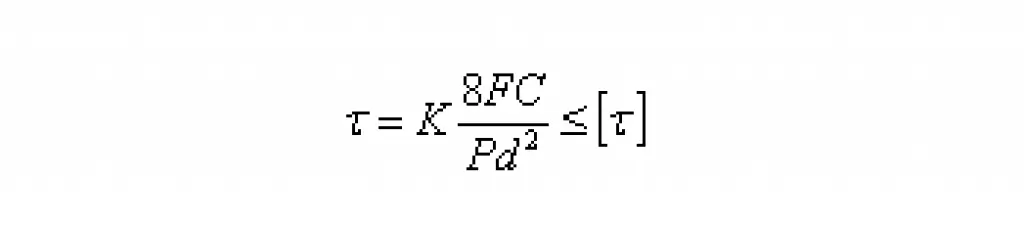

If considering the effect of shear stress caused by shear force F and the helical curvature of the spring wire, the maximum shear stress t occurs on the inner side of the spring in Figure (b), and its numerical value and strength conditions should be:

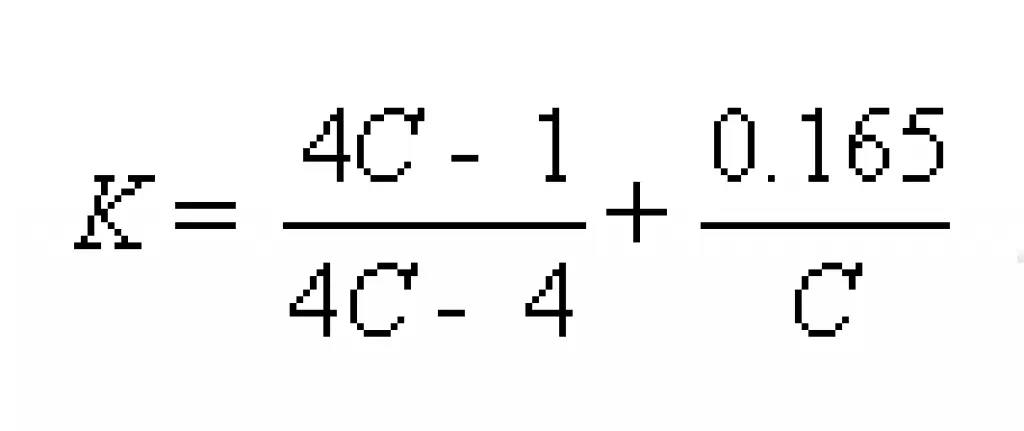

In the formula, C——winding ratio, C=D/d, can be selected according to Table 1

K——spring curvature coefficient,

The Spring Is Not In Place And The Cause Of Failure

In practical work, we often encounter that the spring cannot push the moving object to the set position, which means that the calculated free length of the spring is shortened. The main reason is that there is no initial compression treatment, that is, a manufactured spring is compressed to its compression height or tightening height (if necessary) with a large force, and it cannot be restored to its original state after being released. of free-length operations. The amount of shortening is called “initial compression”. Generally, after 3-6 repetitions of compression, the length is no longer shortened, that is, the spring is “positioned”. The spring is permanently deformed after initial compression.

Spring Preventive Measures

In actual work, the compression spring should be able to maintain its working length even if it is subjected to a force beyond the elastic limit of the material. Therefore, the length of the finished spring should be equal to the calculated length of the spring plus the amount of initial compression, which can prevent the spring from not being in place, so as to avoid dangerous stress when the spring coils are tightened, resulting in an abnormal spring indicating line that is not in place. During the heat treatment process of the finished spring, especially the quenching and tempering process, the workpiece must be placed horizontally (horizontal) in the furnace to prevent the spring from being shortened due to its own weight and the operation is not in place.