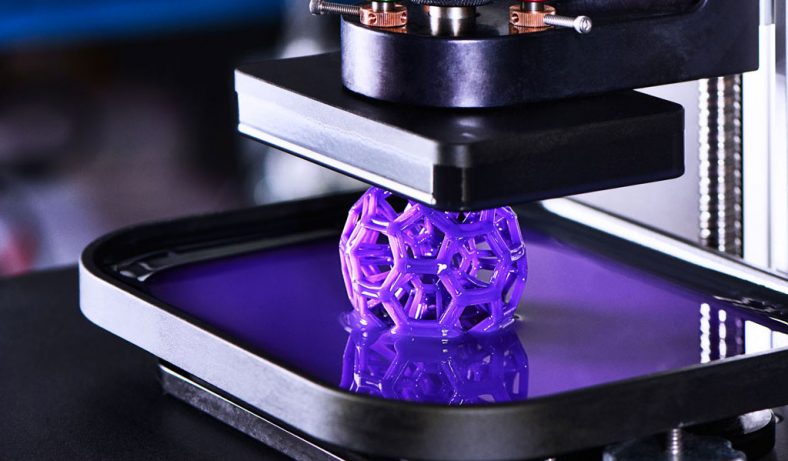

As 3D printing research and development continues, refined technology advances that provide more precise control over higher temperatures, producing high-quality prints with difficult-to-handle materials. High temperature creep. Thermal creep occurs when heat diffuses irregularly through the hot end of the extruder.Fortunately, understanding the causes and implementing effective preventive measures can optimize 3D printer performance and produce flawless prints.In this article, we’ll explore the concept of heat creep in 3D printing and delve into practical strategies to prevent it. Whether you’re a seasoned 3D printing enthusiast or a beginner eager to enhance your printing skills, the insights and techniques shared here will help you prevent and fix heat creep in your 3D printer.

What Is 3D Printing Heat Creep?

Heat creep is a phenomenon that can occur in 3D printing, particularly in the extruder assembly of a 3D printer. It refers to the unwanted transfer of heat from the hot end of the printer (typically the nozzle) into the cold end, which includes the heat sink and the filament feeding mechanism.

The extruder assembly in a 3D printer consists of two main sections: the hot end and the cold end. The hot end contains the nozzle, which is responsible for melting the filament, and a heating element that maintains the desired temperature. The cold end consists of a heat sink and a cooling fan, which help dissipate heat and keep the filament feeding mechanism cool.

Heat creep occurs when the heat from the hot end is transferred into the cold end, disrupting the temperature balance and potentially causing issues. This can happen due to factors such as insufficient cooling, improper fan operation, poor thermal conductivity of the heat break (the transition point between the hot end and the cold end), or extended printing sessions that generate excessive heat.

What Causes Heat Creep in 3D Printing?

Heat creep in 3D printing is typically caused by a combination of factors that affect the balance of heat transfer within the extruder assembly. Here are some common causes of heat creep:

- Insufficient Cooling: The cooling system in the extruder assembly, typically consisting of a heat sink and a cooling fan, may be inadequate to dissipate the heat generated by the hot end. Inadequate cooling can result from a malfunctioning or underpowered cooling fan, improper fan placement, or restricted airflow around the heat sink.

- Improper Thermal Barrier (Heat Break): The heat break, which is the transition point between the hot end and the cold end, plays a crucial role in preventing heat from transferring into the cold end. If the thermal barrier is poorly designed or has low thermal conductivity, it can become a pathway for heat to creep up into the cold end.

- High Ambient Temperature: Operating the 3D printer in an environment with high ambient temperatures can exacerbate heat creep. The surrounding temperature can affect the overall heat dissipation and make it more challenging for the cooling system to maintain proper temperature balance.

- Prolonged Printing Sessions: Continuous or extended printing sessions can generate excessive heat, which can gradually build up and contribute to heat creep. This can be especially problematic if the printer is running at high temperatures or printing complex, time-consuming models.

- Incorrect Print Settings: Inaccurate print settings, such as excessively high nozzle temperature or improper retraction settings, can increase the chances of heat creep. Higher temperatures can cause the filament to soften too early in the cold end, while improper retraction settings may not effectively control the pressure build-up and filament retraction.

- Filament-related Factors: Certain filament characteristics can also influence the likelihood of heat creep. For example, filaments with lower melting points or greater sensitivity to heat can be more susceptible to softening or melting prematurely, contributing to heat creep.

The Consequences Of Heat Creep

- Filament Softening: As heat creeps into the cold end, the filament may start to soften or even melt prematurely. This can result in filament deformation, clogs, and extrusion problems.

- Filament Jamming: Softened filament can solidify within the cold end, leading to filament jams or blockages. This can interrupt the filament feeding process, causing print failures or requiring manual intervention to clear the jam.

- Inconsistent Extrusion: Heat creep can lead to inconsistent extrusion, causing under-extrusion, gaps, or other print quality issues. The flow of the filament can become irregular, resulting in inconsistent layers and compromised print accuracy.

- Print Failures: If heat creep is severe, it can lead to significant extrusion problems and print failures. The print may stop extruding filament altogether or exhibit severe under-extrusion, resulting in incomplete or unusable prints.

Preventing or mitigating heat creep involves several measures, such as optimizing cooling, improving thermal conductivity in the heat break, adjusting print settings, and ensuring proper maintenance and calibration of the 3D printer. By managing heat dissipation effectively, the risk of heat creep can be minimized, resulting in more reliable and consistent 3D printing performance.

How Do You Insulate a 3D Printer Hot End?

Insulating the hot end of a 3D printer can help improve temperature stability, reduce heat loss, and prevent heat from affecting other components(as dlp 3d printing process). Here are some common methods to insulate a 3D printer hot end:

- Insulating Sleeve: One straightforward approach is to use an insulating sleeve or wrap around the hot end. Heat-resistant materials such as silicone or ceramic fiber sleeves can be used to provide insulation. These sleeves are wrapped around the heater block and nozzle, minimizing heat transfer to the surrounding environment.

- High-Temperature Tape: Heat-resistant tape, such as Kapton tape or aluminum foil tape, can be applied to the hot end to provide insulation. The tape is wrapped around the heater block, nozzle, or other exposed hot components to create a barrier that reduces heat loss.

- Thermal Barrier Coating: Certain thermal barrier coatings can be applied to the hot end to improve insulation. These coatings are designed to resist high temperatures and reduce heat transfer. They are typically sprayed or brushed onto the hot end components and provide an additional layer of insulation.

- Insulating Socks or Covers: Insulating socks or covers made of materials like silicone can be slipped over the heater block and nozzle. These socks provide a snug fit and create a thermal barrier, preventing heat loss and reducing the impact of external factors on temperature stability.

- Ceramic Fiber Insulation: Ceramic fiber insulation, such as ceramic tape or insulation blankets, can be wrapped around the hot end to provide effective heat insulation. These materials have excellent thermal resistance and can handle high temperatures. They are wrapped securely around the hot end components, reducing heat transfer to the surroundings.

When insulating the hot end, it’s essential to consider safety and compatibility with the printer’s design. Here are a few tips to keep in mind:

- Ensure that any insulation materials used can withstand the high temperatures generated by the hot end without melting or releasing toxic fumes.

- Do not obstruct ventilation or cooling systems. Insulation should not impede the proper functioning of the cooling fan or other cooling mechanisms.

- Take care not to interfere with the temperature sensors or thermocouples, as accurate temperature readings are crucial for proper operation and control.

- Regularly monitor the hot end and insulation for any signs of wear, damage, or degradation. Replace insulation materials as needed to maintain effectiveness and safety.

- Be cautious with any flammable materials or adhesives used in the insulation process, ensuring they are safely positioned away from heat sources.

Insulating the hot end can contribute to temperature stability, more consistent printing, and improved overall performance. However, it’s important to carefully research and select appropriate insulation materials and techniques based on your specific 3D printer model and requirements.

The Prevent Methods Of Heat Creep

Preventing heat creep in 3D printing is crucial to maintain reliable and consistent printing performance.To avoid heat creep, you can take several measures, including:

- Optimize Cooling: Ensure that the cooling system of your 3D printer is working effectively. This includes verifying that the cooling fan is properly positioned, functioning correctly, and providing sufficient airflow to the heat sink. Adequate cooling helps dissipate heat from the hot end, preventing it from creeping into the cold end.

- Improve Heat Break Design: The heat break, which is the transition point between the hot end and the cold end, plays a critical role in preventing heat transfer. Consider using a well-designed heat break with good thermal conductivity to minimize heat creep. Upgrading to a higher-quality heat break with improved thermal properties can enhance heat dissipation and reduce the chances of heat creep.

- Use Heat-Resistant Materials: Select high-temperature materials for the hot end components, such as the heater block, heat sink, and heat break. Heat-resistant materials can better withstand the high temperatures generated during 3D printing, reducing the likelihood of heat creep.

- Optimize Print Settings: Fine-tuning your print settings can help prevent heat creep. Consider adjusting the nozzle temperature to the appropriate level for the filament being used. Higher nozzle temperatures can increase the chances of heat creep, so find the optimal temperature that balances extrusion efficiency and heat dissipation.

- Proper Retraction Settings: Retraction settings control the retraction and re-priming of filament during print movements. Incorrect retraction settings can lead to increased pressure build-up in the hot end, which can contribute to heat creep. Experiment with different retraction distances and speeds to find the optimal settings for your printer and filament combination.

- Monitor Ambient Temperature: Operating the 3D printer in an environment with excessive heat can exacerbate heat creep. Ensure that the ambient temperature around the printer is within the recommended range. If necessary, consider providing additional ventilation or cooling to the printing area.

- Regular Maintenance and Cleaning: Perform regular maintenance and cleaning of the extruder assembly. Remove any accumulated debris, filament residue, or clogs that can obstruct proper heat dissipation. A clean and well-maintained extruder assembly can help prevent heat buildup and reduce the risk of heat creep.

- Quality Filament: Ensure that you are using high-quality filament from reputable manufacturers. Some lower-quality filaments may have inconsistent melting characteristics or contain impurities that can contribute to heat creep. Opting for reliable and well-tested filament can help mitigate potential issues.

By implementing these preventive measures, you can minimize the occurrence of heat creep and maintain more stable and reliable 3D printing performance. It’s important to note that the specific measures needed may vary depending on your printer model, filament type, and environmental conditions. Regular monitoring and adjustments based on your specific setup will help optimize performance and minimize the risk of heat creep.

High-Quality 3D Printed Parts With Be-Cu.com

Heat creep is a common issue in 3D printing, but it’s possible to prevent. By understanding the causes of 3D printing heat creep and implementing effective prevention measures, 3D printing enthusiasts can enjoy optimal printer performance and produce high-quality prints.

Or, you can work with the China 3D printing experts at Be-Cu.com. Our manufacturing partners are well versed in the measures required to prevent heat creep and deliver high quality printed parts in a variety of materials.