In the dynamic world of precision engineering, CNC (Computer Numerical Control) machines stand as the bedrock, driving innovation, and precision across industries. Behind the scenes of this technological prowess are manufacturers who continuously push the boundaries of excellence. Here, we delve into the realm of the 10 best global CNC machine manufacturers, pioneers shaping the landscape of precision engineering.

Haas Automation, Inc

Haas Automation, Inc. is one of the leading CNC machine manufacturers globally, renowned for its dedication to producing high-quality, reliable, and user-friendly machining equipment. Founded by Gene Haas in 1983, the company has established itself as a powerhouse in the CNC machine industry.Here are some key points highlighting Haas Automation, Inc.’s impact and significance:

- Innovation and Technology: Haas is committed to innovation, continuously integrating the latest technological advancements into its CNC machines. They focus on producing cutting-edge equipment that caters to various industries’ diverse needs, from automotive to aerospace and beyond.

- Product Range: The company offers a wide array of CNC machines, including vertical and horizontal machining centers, CNC lathes, rotary tables, and more. This extensive product line ensures that customers can find machines suited to their specific manufacturing requirements.

- Accessibility and User-Friendliness: Haas CNC machines are revered for their user-friendly interfaces, making them accessible even to those new to CNC machining. The intuitive design of their controls and software has contributed significantly to their popularity among both seasoned professionals and newcomers in the industry.

- Reliability and Support: Haas has built a strong reputation for the reliability of its machines. Moreover, their commitment to customer support, including extensive training programs and responsive service, has contributed to fostering long-term relationships with their clientele.

- Global Presence: With a broad international presence, Haas Automation has established itself in various markets worldwide. Their manufacturing facilities and sales offices span across different continents, ensuring a global reach and accessibility for customers.

- Educational Initiatives: Haas has also been proactive in supporting education in CNC machining. They provide educational discounts, donate equipment to schools and colleges, and offer training programs aimed at fostering the next generation of machinists and engineers.

- Continuous Improvement: The company’s ethos revolves around continuous improvement. They regularly update their machines, incorporate customer feedback, and invest in research and development to stay ahead in an ever-evolving industry.

Haas Automation, Inc.’s commitment to innovation, quality, and customer satisfaction has propelled it to the forefront of the CNC machine manufacturing industry. Their machines’ reliability, ease of use, and technological advancements continue to make them a go-to choice for various manufacturing applications worldwide.

DMG Mori Co., Ltd.

DMG Mori Co., Ltd. stands as a global leader in the manufacturing of CNC machines, renowned for its advanced technology, precision engineering, and comprehensive range of machining solutions. Created through the collaboration of German and Japanese engineering expertise, DMG Mori has established itself as a powerhouse in the industry.Here are some key aspects highlighting DMG Mori Co., Ltd.’s prominence and influence:

- Technological Fusion: Arising from the amalgamation of German company GILDEMEISTER and Japanese company Mori Seiki, DMG Mori embodies a unique blend of German precision and Japanese technological innovation. This fusion has resulted in a company that combines the strengths of both heritages to offer state-of-the-art CNC machines.

- Diverse Product Portfolio: DMG Mori boasts an extensive range of CNC machines, including turning centers, milling machines, multitasking machines, additive manufacturing solutions, and more. This broad spectrum ensures they cater to diverse manufacturing needs across various industries.

- Industry 4.0 Integration: Embracing the concept of Industry 4.0, DMG Mori integrates smart manufacturing solutions into its machines. Their offerings include advanced connectivity, data analytics, and automation features that enhance productivity, efficiency, and predictive maintenance capabilities.

- Global Reach and Customer Support: With a widespread global presence encompassing manufacturing facilities, sales offices, and service centers, DMG Mori ensures comprehensive customer support worldwide. Their commitment to service, maintenance, and training contributes to fostering strong relationships with their clientele.

- Innovative Technology: DMG Mori continuously invests in research and development to stay at the forefront of technological advancements. Their focus on innovation leads to the creation of cutting-edge machines that meet evolving industry demands for precision, speed, and versatility.

- Sustainability Initiatives: The company emphasizes sustainability in its operations, striving to create eco-friendly manufacturing solutions. They promote energy-efficient technologies and sustainable production processes to reduce environmental impact.

- Education and Training Programs: DMG Mori is actively involved in educational initiatives, offering training programs, apprenticeships, and partnerships with educational institutions to promote CNC machining skills and support the development of future talents in the manufacturing industry.

DMG Mori Co., Ltd.’s commitment to technological innovation, comprehensive product offerings, global presence, and dedication to sustainability positions it as a frontrunner in the CNC machine manufacturing landscape. Their focus on integrating cutting-edge technology with traditional precision engineering principles continues to shape the future of manufacturing worldwide.

Mazak Corporation

The Mazak Corporation is a renowned global leader in the manufacturing of advanced CNC machine tools and systems. Established in 1919 in Japan, Mazak has evolved into a pioneering force in precision machining, consistently pushing the boundaries of innovation and technology in the industry.Here’s an overview highlighting Mazak Corporation’s significance and impact:

- Advanced Technology and Innovation: Mazak is synonymous with cutting-edge technology in CNC machining. They are known for their continual innovation, introducing advanced features such as multi-tasking capabilities, hybrid manufacturing solutions, and intelligent machine monitoring systems.

- Extensive Product Range: The company offers a diverse portfolio of CNC machines, including vertical and horizontal machining centers, turning centers, 5-axis machines, laser processing machines, and more. This broad range caters to various industries and manufacturing requirements.

- Smart Manufacturing Solutions: Mazak is at the forefront of implementing Industry 4.0 principles. They integrate smart manufacturing concepts, such as the Mazak SmartBox for data-driven insights, connectivity solutions, and automation, to enhance productivity and efficiency in manufacturing operations.

- Global Presence and Support: With a widespread global network of manufacturing facilities, technology centers, and service locations, Mazak ensures comprehensive customer support. Their commitment to service, spare parts availability, and training programs strengthens their relationships with customers worldwide.

- Focus on Quality and Precision: Mazak’s machines are renowned for their precision, reliability, and quality. Their dedication to stringent quality control measures and precision engineering ensures that their machines meet the highest standards of performance and accuracy.

- Environmental Consciousness: Mazak prioritizes environmental sustainability in manufacturing processes. They aim to reduce energy consumption, waste, and environmental impact through eco-friendly initiatives and energy-efficient technologies.

- Educational Partnerships and Training: Mazak collaborates with educational institutions, providing training programs, apprenticeships, and educational support to develop skilled professionals in CNC machining and manufacturing.

- Customer-Centric Approach: Mazak places great emphasis on understanding and meeting customer needs. They actively engage with customers to tailor solutions, provide consultations, and adapt their technology to suit specific applications and industries.

Mazak Corporation’s commitment to innovation, technological excellence, global outreach, and customer satisfaction solidifies its position as a frontrunner in the CNC machine manufacturing domain. Their relentless pursuit of advancements continues to shape the future of precision manufacturing worldwide.

Okuma Corporation

The Okuma Corporation is a globally recognized leader in the manufacturing of CNC machine tools and machining solutions. Established in Japan in 1898, Okuma has maintained its reputation for innovation, precision, and reliability in the field of manufacturing technology.Here are key points highlighting Okuma Corporation’s significance and impact:

- Innovative CNC Technology: Okuma is renowned for its innovative CNC machine tools, encompassing a wide range of solutions such as vertical and horizontal machining centers, multitasking machines, grinders, and more. Their focus on technological advancements consistently brings forth cutting-edge solutions for various industries.

- Intelligent Machining Solutions: Okuma places emphasis on intelligent machining systems, integrating smart technologies like AI (Artificial Intelligence), IoT (Internet of Things), and automation to optimize productivity, improve accuracy, and enable predictive maintenance in manufacturing processes.

- High Precision and Quality: The company is recognized for its commitment to precision engineering and high-quality manufacturing standards. Okuma machines are known for their accuracy, durability, and reliability, catering to industries requiring meticulous precision in their operations.

- Global Presence and Customer Support: With a global network of manufacturing facilities, sales offices, and service centers, Okuma ensures comprehensive customer support. Their dedication to customer service, technical assistance, and spare parts availability contributes to strong relationships with customers worldwide.

- Continuous Research and Development: Okuma places a strong emphasis on research and development to stay ahead in technological advancements. Their investment in R&D drives continuous improvement, ensuring their machines remain at the forefront of industry standards.

- Sustainability Initiatives: Okuma is committed to sustainable manufacturing practices. They focus on eco-friendly technologies, energy-efficient processes, and waste reduction strategies to minimize their environmental footprint.

- Educational Support and Training Programs: Okuma actively engages in educational partnerships and training programs, aiming to foster skilled professionals in CNC machining and manufacturing. They offer educational support, training seminars, and collaborations with educational institutions to develop future talents in the industry.

- Customized Solutions and Adaptability: Okuma’s customer-centric approach involves understanding unique customer needs and providing tailored solutions. They work closely with clients to customize machines and technologies for specific applications and industries.

Okuma Corporation’s commitment to innovation, precision engineering, global outreach, and sustainability places it as a leader in the CNC machine manufacturing sector. Their dedication to advancing manufacturing technologies continues to drive efficiency, accuracy, and progress across diverse industries worldwide.

Makino Milling Machine Co., Ltd

Makino Milling Machine Co., Ltd., established in 1937 in Japan, is a highly regarded global manufacturer of advanced machining centers and solutions for precision machining applications. Known for its commitment to high-speed, high-precision machining, Makino has established a strong reputation in the manufacturing industry.Key points highlighting Makino Milling Machine Co., Ltd.’s significance and impact include:

- High-Speed Machining Expertise: Makino specializes in high-speed machining centers, providing solutions for industries demanding ultra-precision and high-efficiency machining. Their machines excel in producing complex parts with tight tolerances at accelerated speeds.

- Advanced Technology Integration: The company is at the forefront of incorporating cutting-edge technology into its machining solutions. Makino’s machines often integrate innovative features like advanced control systems, IoT connectivity, and automation for improved productivity and accuracy.

- Precision and Quality Focus: Makino machines are known for their exceptional precision, reliability, and quality. Their emphasis on meticulous engineering and stringent quality control measures ensures that their machining centers meet the highest industry standards.

- Wide Range of Machining Solutions: Makino offers a diverse portfolio of machining solutions, including vertical and horizontal machining centers, 5-axis machines, EDM (Electrical Discharge Machining) equipment, and automation systems, catering to various manufacturing needs.

- Global Presence and Customer Support: With a widespread global network of sales and service centers, Makino ensures excellent customer support. Their dedication to service, maintenance, spare parts availability, and technical assistance strengthens their relationships with customers worldwide.

- Continuous Innovation and R&D: Makino invests significantly in research and development to pioneer new technologies and machining techniques. This commitment to innovation drives continuous improvement in their products, keeping them at the forefront of technological advancements.

- Education and Training Programs: Makino actively supports educational initiatives, providing training programs, technical seminars, and collaborations with educational institutions. These efforts aim to foster the development of skilled professionals in CNC machining and manufacturing.

- Adaptability and Customization: Makino’s customer-centric approach involves understanding specific customer needs and tailoring solutions accordingly. They work closely with clients to customize machines and technologies for specialized applications and industries.

Makino Milling Machine Co., Ltd.’s dedication to high-speed precision machining, technological innovation, global outreach, and commitment to quality solidifies its position as a leading provider of advanced machining solutions in the manufacturing industry. Their focus on pushing the boundaries of machining capabilities continues to drive efficiency and advancement across various industrial sectors.

FANUC Corporation

FANUC Corporation is a global pioneer in factory automation, robotics, and CNC systems, renowned for its cutting-edge technology and innovation in the manufacturing industry. Established in 1956 in Japan, FANUC has significantly contributed to industrial automation and CNC machining.Key aspects highlighting FANUC Corporation’s significance and impact include:

- Leadership in Industrial Robotics: FANUC is a dominant force in industrial robotics, producing a wide range of robots used in various industries, including automotive, electronics, and more. Their robots are known for their precision, reliability, and efficiency in automation.

- CNC Systems Expertise: FANUC is a key player in the development of CNC systems for machine tools. Their CNC systems are highly regarded for their precision, speed, and advanced features, empowering manufacturers to achieve high-quality machining.

- Innovative Technology Integration: The company continuously integrates innovative technologies like AI, IoT, and machine learning into their products. Their focus on smart manufacturing solutions ensures increased productivity, predictive maintenance, and seamless connectivity within manufacturing environments.

- Global Presence and Customer Support: FANUC has a strong global presence with sales and service networks spanning across numerous countries. Their commitment to customer service, technical support, training programs, and spare parts availability ensures comprehensive support for customers worldwide.

- Commitment to Research and Development: FANUC invests significantly in R&D, driving continuous innovation and improvement in their products. This dedication to technological advancements keeps their robotics and CNC systems at the forefront of the industry.

- Reliability and Durability: FANUC machines and robots are known for their robustness, durability, and longevity. This reliability makes them a preferred choice for industries requiring high precision and continuous operation.

- Education and Training Initiatives: FANUC actively supports education in robotics and automation. They offer training programs, educational partnerships, and collaborations with institutions to equip individuals with the skills required for careers in automation and manufacturing.

- Adaptability and Custom Solutions: FANUC collaborates with customers to provide tailored solutions. They understand unique industry requirements and develop customized robotic and CNC solutions to address specific manufacturing needs.

FANUC Corporation’s pioneering contributions to industrial robotics, CNC systems, and factory automation have significantly impacted the manufacturing landscape. Their innovative technologies continue to drive efficiency, precision, and automation across various industries, shaping the future of manufacturing.

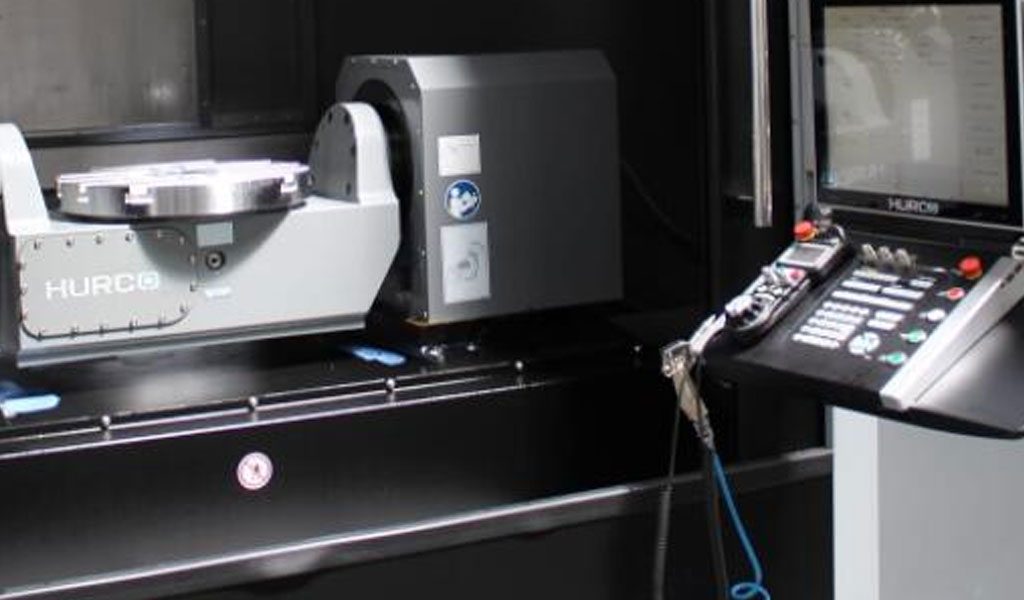

Hurco Companies, Inc.

Hurco Companies, Inc. is a prominent player in the manufacturing of computerized machine tools, particularly known for its innovative CNC machining solutions. Founded in 1968, Hurco has gained recognition for its focus on user-friendly CNC technology and versatile machining centers.Key points highlighting Hurco Companies, Inc.’s significance and impact include:

- User-Friendly CNC Technology: Hurco is celebrated for its intuitive and user-friendly CNC machine interfaces. Their proprietary control system, the WinMax®, provides a straightforward programming environment that is both powerful and easy to use, catering to both seasoned professionals and newcomers in the industry.

- Versatile Machining Solutions: The company offers a diverse range of CNC machines, including vertical machining centers, horizontal machining centers, and 5-axis machining centers. Hurco’s machines are designed to handle a variety of applications, providing flexibility for different manufacturing needs.

- Focus on Precision and Accuracy: Hurco emphasizes precision engineering, ensuring their machines deliver high accuracy and repeatability. This focus on accuracy is crucial for industries requiring intricate and precise machining processes.

- Innovative Technology Integration: Hurco incorporates innovative technologies into its machines, such as advanced control software, high-speed machining capabilities, and responsive design, enabling faster production times and improved efficiency.

- Global Reach and Support: With a global presence in multiple countries, Hurco ensures comprehensive customer support. Their sales and service network, coupled with training programs and technical assistance, enhances their support system for customers worldwide.

- Continuous Improvement and Adaptability: Hurco is committed to continuous improvement and adapts its technology to meet evolving industry demands. They actively seek customer feedback and incorporate suggestions into the development of new features and functionalities.

- Customization and Customer-Centric Approach: Hurco collaborates closely with customers to provide customized solutions tailored to specific applications or industries. Their adaptable approach allows for the customization of machines to suit unique manufacturing requirements.

- Educational Initiatives: Hurco supports educational programs and partnerships to promote CNC machining skills. They provide training and educational resources, aiming to develop the next generation of skilled professionals in manufacturing.

Hurco Companies, Inc.’s commitment to user-friendly technology, precision engineering, innovation, and customer-centric approaches has positioned it as a respected provider of CNC machining solutions. Their focus on versatility and ease of use continues to attract customers seeking efficient and reliable machining solutions for various applications.

Doosan Group (Doosan Machine Tools)

Doosan Group, particularly Doosan Machine Tools, is a prominent global manufacturer of machine tools, including CNC machine tools and solutions for various industries. Established in South Korea, Doosan Machine Tools has gained recognition for its diverse product range and technological advancements.Key points highlighting Doosan Machine Tools’ significance and impact include:

- Extensive Product Portfolio: Doosan Machine Tools offers a comprehensive lineup of CNC machine tools, including vertical and horizontal machining centers, turning centers, multitasking machines, and more. Their diverse range caters to different machining needs across various industries.

- Advanced Technology Integration: The company emphasizes the integration of cutting-edge technologies into its machines. Doosan Machine Tools incorporates innovative features such as high-speed machining capabilities, smart controls, and automation solutions to enhance productivity and efficiency.

- Precision and Reliability: Doosan machines are known for their precision, reliability, and high-performance capabilities. Their focus on accuracy and durability ensures that their machines meet the stringent demands of precision machining applications.

- Global Presence and Support: With a strong global presence, Doosan Machine Tools has established sales and service networks worldwide. Their commitment to customer service, technical support, spare parts availability, and training programs strengthens their relationships with customers across the globe.

- Continuous Innovation and R&D: Doosan invests in research and development to drive innovation and technological advancements. Their focus on continual improvement ensures that their machines remain competitive and aligned with industry standards.

- Environmental Responsibility: Doosan is committed to sustainability and eco-friendly manufacturing practices. They aim to reduce energy consumption, waste, and environmental impact through the adoption of energy-efficient technologies and sustainable processes.

- Customization and Adaptability: Doosan Machine Tools collaborates with customers to offer customized solutions tailored to specific machining requirements. Their ability to adapt and customize machines for diverse applications contributes to their appeal across different industries.

- Education and Training Initiatives: Doosan supports educational initiatives, providing training programs, technical seminars, and partnerships with educational institutions to promote CNC machining skills and cultivate a skilled workforce.

Doosan Machine Tools’ commitment to technological innovation, diverse product offerings, global reach, and dedication to quality and customer support cements its position as a reputable provider of CNC machine tools. Their focus on precision engineering and adaptability continues to address the evolving needs of manufacturing industries worldwide.

Yamazaki Mazak Corporation

Yamazaki Mazak Corporation stands as a global leader in the manufacturing of advanced CNC machine tools and systems, renowned for its commitment to innovation, precision engineering, and comprehensive range of machining solutions. Established in 1919 in Japan, Mazak has evolved into a pioneering force in the industry.Key aspects highlighting Yamazaki Mazak Corporation’s significance and impact include:

- Cutting-edge Technology: Mazak is synonymous with advanced technology in CNC machining. They continuously innovate and introduce cutting-edge features in their machines, such as high-speed spindles, multitasking capabilities, and smart manufacturing integration, ensuring high efficiency and precision.

- Diverse Product Portfolio: The company offers a wide array of CNC machines, including vertical and horizontal machining centers, turning centers, multi-axis machines, laser processing machines, and more. This extensive range caters to diverse manufacturing needs across various industries.

- Smart Manufacturing Solutions: Yamazaki Mazak integrates smart manufacturing concepts into its machines. Their Mazak SmartBox, along with other connectivity solutions and automation features, enables data-driven insights and enhanced productivity within manufacturing environments.

- Global Presence and Customer Support: With a global network of manufacturing facilities, technology centers, and service locations, Mazak ensures comprehensive customer support. Their dedication to service, maintenance, spare parts availability, and technical assistance contributes to strong relationships with customers worldwide.

- Emphasis on Quality and Precision: Mazak machines are acclaimed for their precision, reliability, and quality. Their commitment to strict quality control measures and precision engineering ensures that their machines meet the highest standards of performance and accuracy.

- Innovation through Research and Development: Yamazaki Mazak Corporation invests significantly in research and development to pioneer new technologies and machining techniques. This dedication to innovation drives continuous improvement in their products, keeping them at the forefront of technological advancements.

- Sustainability Initiatives: Mazak places importance on sustainable manufacturing practices. They focus on eco-friendly technologies, energy-efficient processes, and waste reduction strategies to minimize environmental impact.

- Education and Training Programs: Yamazaki Mazak actively supports educational initiatives by offering training programs, technical seminars, and collaborations with educational institutions. These efforts aim to develop skilled professionals in CNC machining and manufacturing.

Yamazaki Mazak Corporation’s commitment to technological innovation, precision engineering, global outreach, and sustainability places it as a leading provider of advanced machining solutions in the manufacturing industry. Their relentless pursuit of advancements continues to drive efficiency, accuracy, and progress across various industrial sectors worldwide.

GF Machining Solutions

GF Machining Solutions is a renowned global provider of manufacturing solutions and services, particularly known for its expertise in precision machining, electrical discharge machining (EDM), milling, and automation technologies. The company, part of GF (Georg Fischer) Group, has established itself as a leader in the field of advanced manufacturing.Here are key aspects highlighting GF Machining Solutions’ significance and impact:

- Precision Machining Excellence: GF Machining Solutions specializes in high-precision machining solutions, offering a comprehensive range of technologies, including milling, EDM, laser texturing, and automation solutions. Their machines cater to industries requiring intricate and precise manufacturing processes.

- Cutting-edge Technology Integration: The company is at the forefront of incorporating advanced technologies into its machining solutions. GF Machining Solutions integrates innovative features such as digitalization, IoT connectivity, and automation to enhance productivity, accuracy, and efficiency.

- Versatile Product Portfolio: GF provides a wide range of machining solutions, including high-speed milling machines, wire-cut and sinker EDM machines, laser machines, and automation systems. Their diverse portfolio addresses various manufacturing needs across industries.

- Global Presence and Customer Support: With a strong global presence and a network of sales and service centers worldwide, GF Machining Solutions ensures excellent customer support. Their commitment to service, technical assistance, and spare parts availability strengthens their relationships with customers globally.

- Focus on Quality and Reliability: GF’s machines are known for their quality, reliability, and high-performance capabilities. Their commitment to precision engineering ensures that their machines meet the demanding requirements of precision manufacturing applications.

- Innovation through Research and Development: GF Machining Solutions invests heavily in research and development to drive innovation in machining technologies. This dedication to advancing technology ensures that their machines remain competitive and aligned with industry standards.

- Sustainability Initiatives: The company emphasizes sustainability in manufacturing processes. GF focuses on eco-friendly technologies, energy-efficient practices, and waste reduction strategies to minimize environmental impact.

- Educational Support and Training Programs: GF Machining Solutions supports educational initiatives, offering training programs, technical seminars, and partnerships with educational institutions. These efforts aim to develop skilled professionals in CNC machining and manufacturing.

GF Machining Solutions’ commitment to technological innovation, precision engineering, global outreach, and sustainability solidifies its position as a respected provider of advanced machining solutions. Their focus on versatility, precision, and efficiency continues to drive advancements in manufacturing across various industries worldwide.

In Conclusion

In conclusion, the landscape of CNC machine manufacturing is enriched by the contributions of these ten exemplary global companies. Each of these manufacturers, including Haas Automation, DMG Mori, Mazak Corporation, Okuma Corporation, Makino Milling Machine Co., FANUC Corporation, Hurco Companies, Doosan Machine Tools, Yamazaki Mazak Corporation, and GF Machining Solutions, has left an indelible mark on the industry through innovation, precision engineering, and a commitment to customer satisfaction.

Their collective impact extends across various industries, from automotive and aerospace to electronics and beyond. These companies have consistently pushed the boundaries of technology, integrating advanced features, embracing smart manufacturing concepts, and focusing on user-friendly interfaces to meet the evolving demands of precision engineering.

Moreover, their dedication to global reach, comprehensive customer support, sustainability initiatives, educational collaborations, and continuous improvement through research and development showcases their commitment not only to technological advancement but also to the development of a skilled workforce and sustainable manufacturing practices.

As technology continues to advance and industries evolve, these manufacturers will undoubtedly continue to shape the future of CNC machining, fostering innovation, efficiency, and precision across the manufacturing landscape. Their unwavering dedication to excellence stands as a testament to their pivotal role in driving the industry forward.