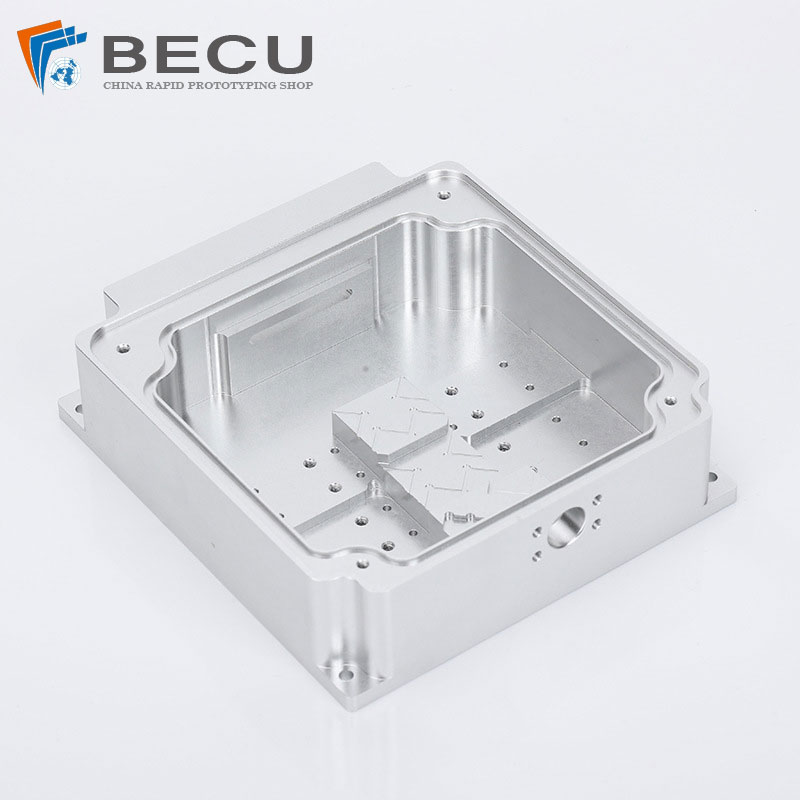

Optical Instrument Sight Bracket

- Product Name: Aluminum Parts

- No+Color:Custom

- Surface Treatment: Anodized Oxidation

- Product Material: Aluminum 7075

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Cnc Machining

- Machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Optical Machining

- Production Process: Cnc Machining

- Size: According To Customer’s Drawings

What Is Electron Optical Instrument Sight Bracket

Electron optical instrument sight bracket, also known as an electron sight bracket or simply a sight bracket, is a component used in electron optical instruments. It is specifically designed to hold and position the sight or targeting system within the electron optics assembly. Electron optical instruments, such as electron microscopes or electron beam lithography systems, use electron beams instead of light to create images or perform precision operations at the nanoscale.

The electron sight bracket plays a crucial role in electron optical instruments by securely holding and positioning the sight or targeting system. Its design and functionality are tailored to the specific requirements of the instrument, ensuring accurate alignment and precise operation of the electron beam.

The Sight Bracket Serves Several Important Functions

- Mounting and Stability: The sight bracket provides a secure and stable platform for attaching the sight or targeting system within the electron optics assembly. It ensures that the sight remains in a fixed position during operation, enabling accurate positioning and alignment of the electron beam.

- Adjustability: The sight bracket often incorporates adjustable features that allow fine-tuning and precise alignment of the sight or targeting system. These adjustment mechanisms enable operators to align the sight with the electron beam or adjust the position for specific imaging or operation requirements.

- Compatibility: The sight bracket is designed to be compatible with the specific electron optical instrument it is used in. It may have standardized mounting interfaces or be custom-designed to fit the instrument’s unique configuration.

- Material and Construction: The sight bracket is typically made of durable materials, such as aluminum or stainless steel, to provide structural strength and stability. The bracket may have a rigid frame or be adjustable through mechanical linkages or precision slides.

- Vibration Damping: In some cases, the sight bracket may incorporate vibration-damping features to minimize any unwanted movement or vibrations that could affect the performance of the electron optical instrument.

- Integration: The sight bracket is an integral part of the electron optics assembly, working in conjunction with other components, such as lenses, apertures, and detectors, to ensure accurate beam control and positioning.

High-Quality Customized Electron Optical Instrument Sight Bracket

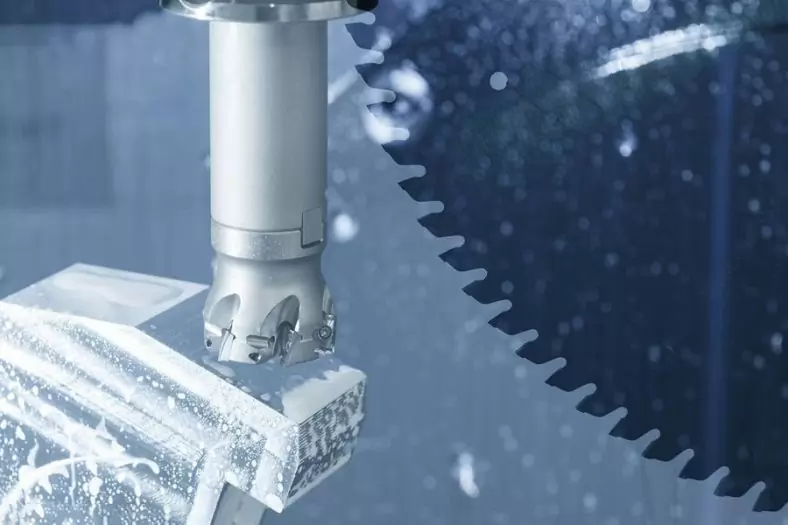

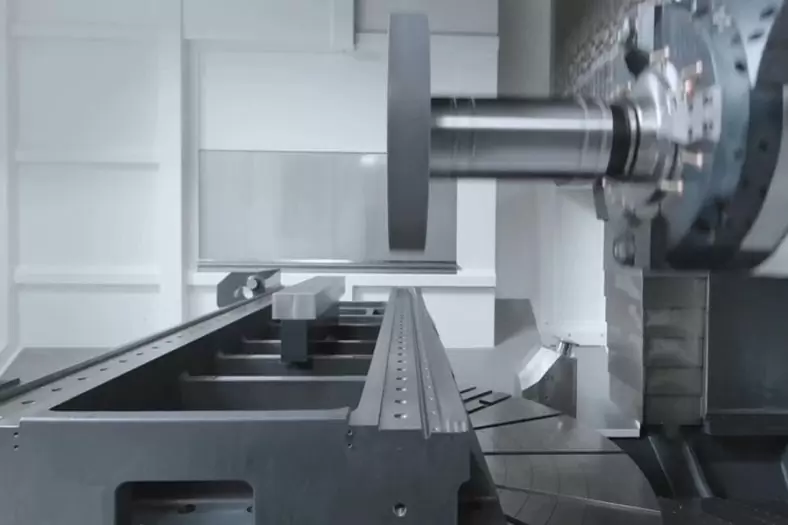

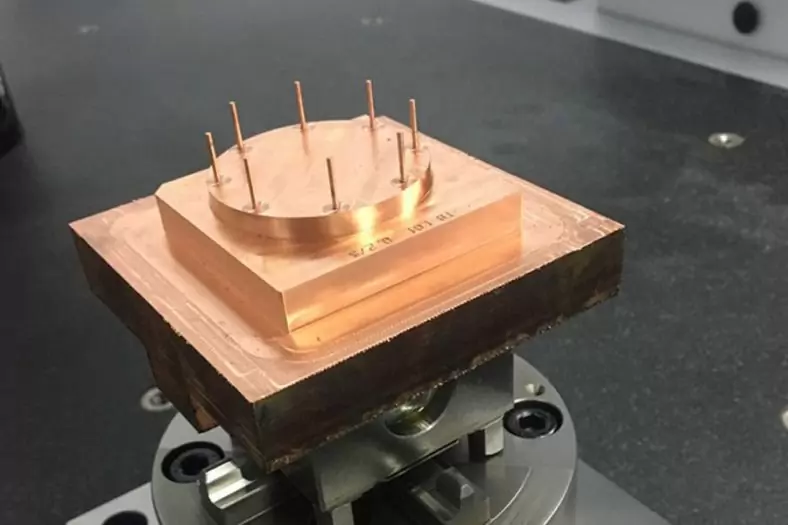

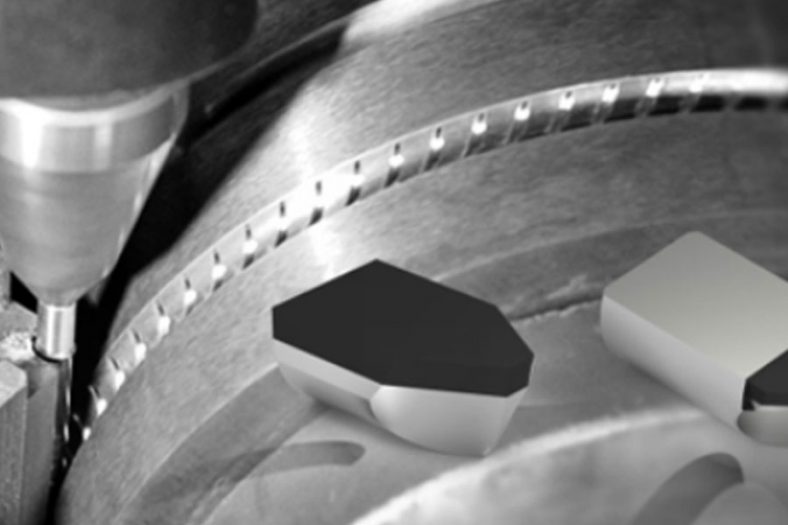

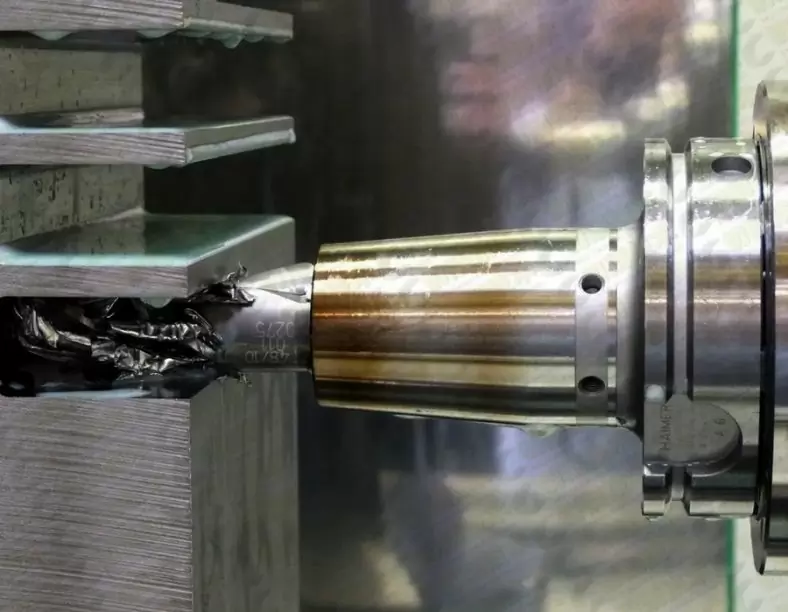

3+2 axis CNC machining refers to a specific machining technique used in the production of complex parts and components, such as an electron optical instrument sight bracket. In 3+2 axis CNC machining, the CNC machine is capable of performing three-axis movements for cutting and shaping the part along with an additional two-axis positioning for machining from different angles.3+2 axis CNC machining offers advantages in terms of repeatability, complex geometries, and high-quality finishes

As one of the leading precision China CNC machining services suppliers , Be-Cu Prototype has strong capabilities to serve your needs of CNC machined parts, from rapid prototyping to precision parts and tooling machining, to end-use parts.Be-Cu Prototype provides you with a reliable one-stop CNC machining service, which provides rapid prototyping/end-use part production in a variety of materials, and related machining services to small, medium, and large-sized cnc machining parts.

The Advantages Of Customized Electron Optical Instrument Sight Bracket

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Customized 3+2 Axis Machining Electron Optical Instrument Sight Bracket

| Material | Aluminum 7075 Machining |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Automotive,Motorcycle |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Milling Company

Looking for low cost CNC milling parts with unparalleled quality? BE-CU Prototype is a professional China CNC company provides superior precision CNC milling service with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning. Our high-quality rapid CNC milling products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc.