Cnc Machining For Polycarbonate – What Is PC CNC Machining

CNC machining for polycarbonate refers to the process of using Computer Numerical Control (CNC) machines to shape, cut, or mill polycarbonate material into desired shapes or forms. Polycarbonate is a type of thermoplastic known for its transparency, strength, and impact resistance, making it a popular choice for various applications ranging from industrial parts to consumer products.

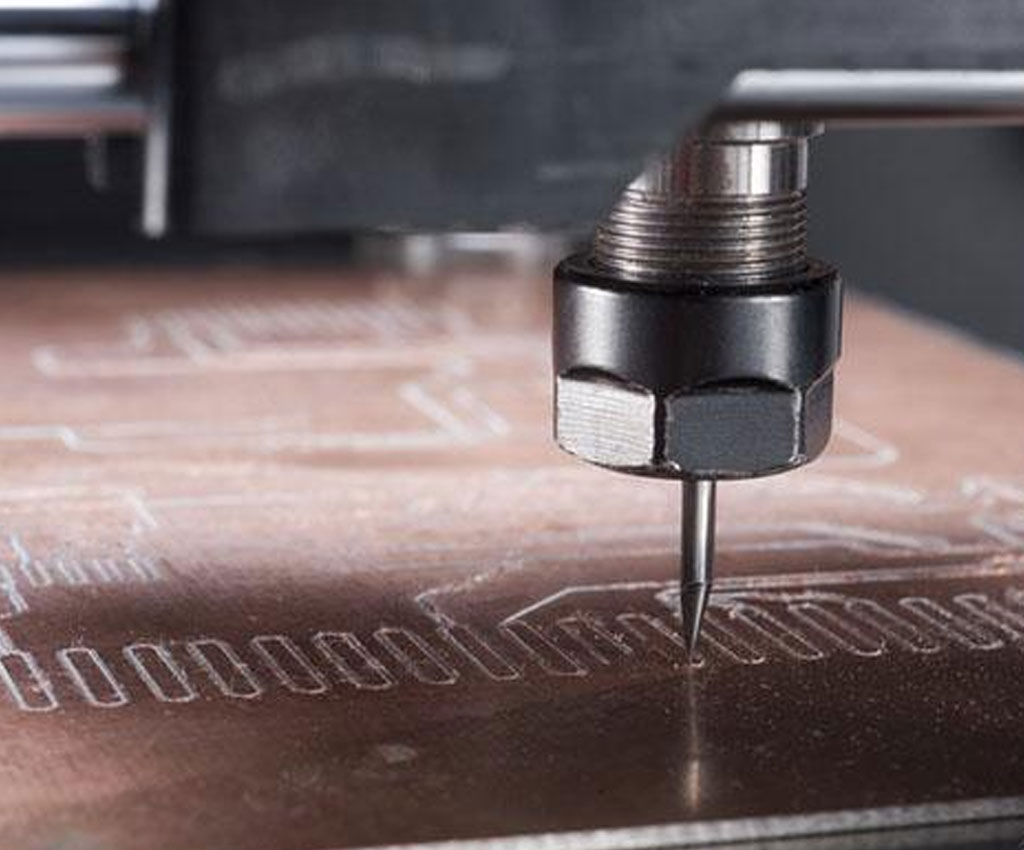

CNC machining involves programming precise instructions into a computer that controls the movement of the cutting tools. This process allows for highly accurate and intricate cuts, holes, or shapes to be made on polycarbonate sheets or blocks according to the specified design.CNC machined PC parts are engineered to possess optical clarity, durability, and resistance to static electricity, making them suitable for various optical applications in industries like electronics, automotive, aerospace, and more.

| No. | Tensile Strength at Yield | Flexural Modulus | Tensile Elongation at Break |

|---|---|---|---|

| Test Method | ASTM D638 | ASTM D790 | ASTM D638 |

| Translucent | 8,000 psi | 340,000 | 50% |

| Clear | 8,990 psi | 338,000 | 140% |

| 20% Glass-Filled | 16,000 | 796,000 | 5% |

Be-Cu Prototype Inc has experienced CNC machinists or experts familiar with PC machining to optimize the process and achieve your desired results.

Polycarbonate Cnc Machining Service – Custom CNC PC Parts Suppliers

If you’re looking for a readily available plastic with a High impact strength,Good machinability and Excellent dimensional stability, Polycarbonate could be the right choice for your project.

Be-Cu Prototype Co. specializes in Polycarbonate CNC Machining(Polycarbonate CNC Milling,Polycarbonate CNC Turning and Polycarbonate 5 Axis Machining).With over 30 years of engineering expertise we are dedicated to offering the highest quality Polycarbonate CNC machining and other products.

For your custom PC CNC machining design, or reverse engineering, our exemplary service and efficient production ensures prompt deliveries coupled with outstanding service.

CNC Milling Polycarbonate

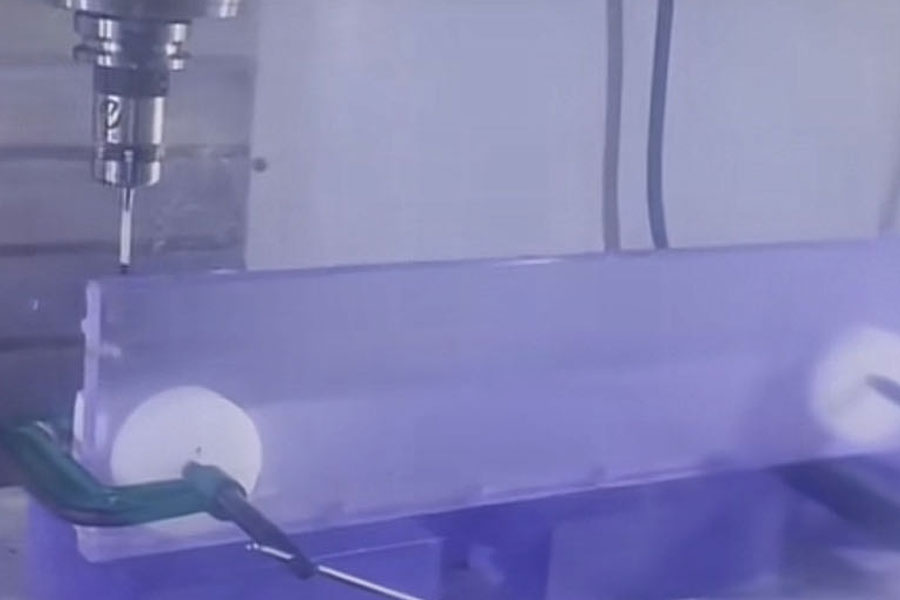

CNC milling of polycarbonate refers to the process of using Computer Numerical Control (CNC) machines to precisely shape, cut, or mill polycarbonate material into desired forms, shapes, or components. Polycarbonate is a type of thermoplastic known for its transparency, impact resistance, and versatility, making it a popular material choice in various industries.

During CNC milling of polycarbonate, it’s crucial to manage cutting speeds, feeds, and coolant usage to prevent overheating or melting of the material. Maintaining proper machining parameters helps achieve precise results without compromising the integrity or quality of the polycarbonate workpiece.CNC milling offers high precision and repeatability, making it a preferred method for shaping polycarbonate into intricate designs or specific components used in various industries, including aerospace, automotive, electronics, and more.

CNC Turning Polycarbonate

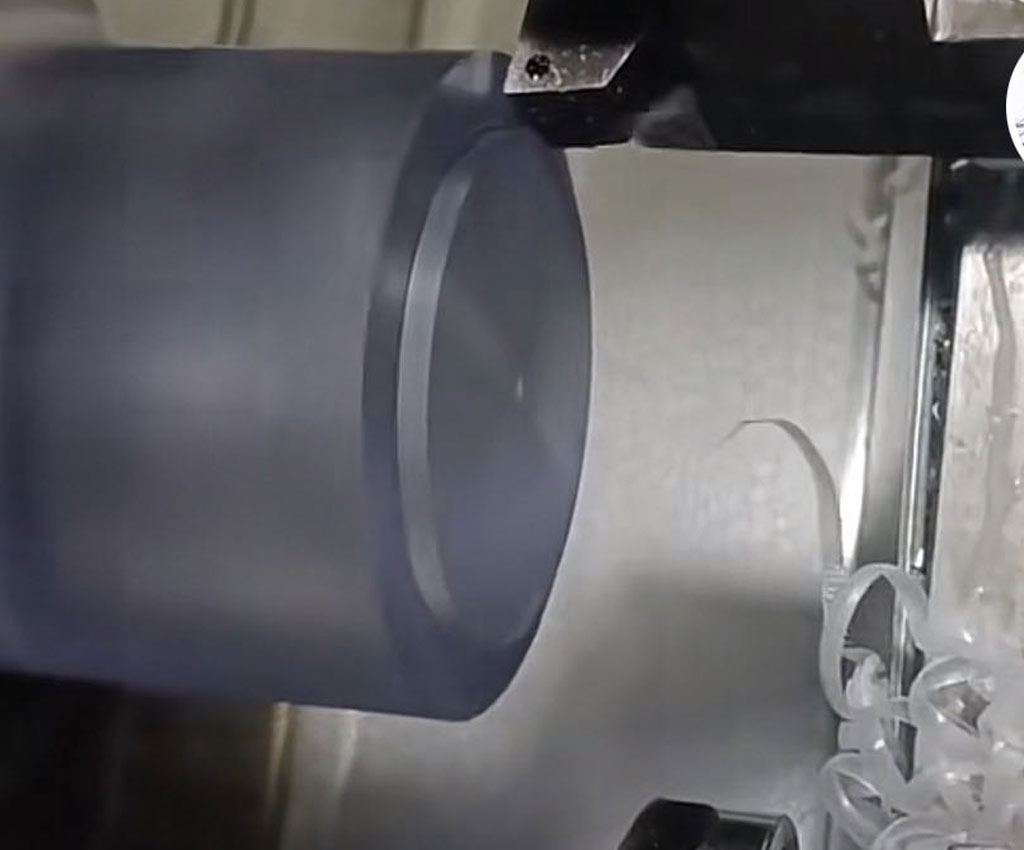

CNC turning of polycarbonate involves using Computer Numerical Control (CNC) machines equipped with lathes to shape polycarbonate rods, bars, or billets into desired cylindrical or rotational parts. Polycarbonate, known for its transparency, impact resistance, and machinability, is suitable for CNC turning processes.

During CNC turning of polycarbonate, maintaining proper cutting speeds, feeds, and tooling is crucial to prevent overheating or deformation of the material. Cooling techniques may also be employed to manage heat generated during the machining process and ensure the quality of the finished part.CNC turning is commonly used to produce various cylindrical components, including bushings, shafts, connectors, and other rotational parts, utilizing the advantages of precision and efficiency offered by CNC machining for polycarbonate materials.

In addition to custom CNC PC Parts and reverse engineering we also provide emergency manufacturing and delivery, engineering, Polycarbonate laser cut, PC Injection Molding and value-added manufacturing solutions.

Polycarbonate Grades We Work With

There are various grades and types of polycarbonate available, each tailored to specific applications and requirements. Some common polycarbonate grades include:

CNC Machining General-Purpose Polycarbonate (GPC)

CNC Machining UV-Resistant Polycarbonate

CNC Machining Flame-Retardant Polycarbonate

CNC Machining Glass-Filled Polycarbonate

CNC Machining Bullet-Resistant Polycarbonate

CNC Machining Medical-Grade Polycarbonate

Food-Grade Polycarbonate complies with regulations set for food-contact applications, ensuring safety for use in items like food containers, kitchenware, and equipment used in the food industry.

The choice of polycarbonate grade depends on the specific properties required for the intended application. CNC machining can be applied to various polycarbonate grades, allowing for precise shaping, cutting, and milling according to the needs of the project or product. When working with CNC machining for polycarbonate, it’s essential to select the appropriate grade based on factors such as mechanical properties, environmental conditions, regulatory requirements, and end-use applications.

Advantages Of PC Machining

- Great precision and high tolerance ensure high-quality Polycarbonate parts

- Time and cost-saving, great speed of Machining Polycarbonate part

- Allows products ordered to be made precisely to the specifications stated

- Complex Polycarbonate parts for high tech industry can be machined

Why Choose Our PC Cnc Machining Service?

- Save time and money for your Polycarbonate project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of Polycarbonate grades and alloy materials can be machined

- Custom complex Polycarbonate machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Polycarbonate Cnc Machined Case Studies In China

Whether you require machined Polycarbonate prototypes or custom Polycarbonate parts for your electronic,led light,optics,automotive, aerospace applications or medical device component, we can easily help you. With our expertise in CNC Polycarbonate machining and the ability to integrate external combined processes, we can ensure the best performance for your machining pc projects.Understanding the properties of different Polycarbonate plastics, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on PC Plastic. Be-cu prototyping company provides a range of solutions for the machining of PC parts.