Laser Cutting For Polycarbonate

In the realm of modern manufacturing and design, laser cutting has emerged as a transformative technology, offering unparalleled precision and versatility across various materials. Among these materials, polycarbonate stands out for its durability, transparency, and diverse applications. Laser cutting, as a method of shaping and manipulating polycarbonate, has become increasingly popular due to its ability to achieve intricate designs, smooth finishes, and high levels of accuracy.

Polycarbonate, a thermoplastic polymer known for its remarkable strength and transparency, has found wide-ranging applications in industries such as aerospace, automotive, electronics, and even in everyday consumer products.Its exceptional impact resistance, coupled with its optical clarity, makes it an ideal choice for items like safety goggles, electronic display screens, protective shields, and various structural components.

Laser cutting, a non-contact subtractive manufacturing process, utilizes a highly focused laser beam to slice through materials precisely. The heat from the laser effectively melts, vaporizes, or blows away the material along the predetermined cutting path, guided by computer-aided designs (CAD).

When applied to polycarbonate, this technology offers numerous advantages. Unlike traditional cutting methods that may result in material warping or rough edges, laser cutting provides a clean, burr-free finish, maintaining the integrity of the polycarbonate’s structural properties.

Laser cutting has revolutionized the manufacturing landscape by providing a highly efficient and precise method for working with materials like polycarbonate. Its ability to create intricate designs while maintaining the structural integrity of the material makes it an invaluable tool across various industries.

PC ( Polycarbonate ) Material Properties

The precise nature of laser cutting minimizes material wastage, making it a cost-effective option for manufacturers aiming to optimize resource utilization.Here is a table outlining the properties of Polycarbonate (PC):

| Property | Description |

|---|---|

| Chemical Formula | (C16H14O3)n |

| Common Names | PC, Lexan, Makrolon |

| Density | 1.20 – 1.22 g/cm³ |

| Transparency | High optical clarity |

| Impact Strength | Extremely high; 250 times stronger than glass |

| Tensile Strength | 55-75 MPa |

| Flexural Strength | 90-120 MPa |

| Thermal Conductivity | 0.19 – 0.22 W/m·K |

| Heat Deflection Temperature | 270 – 310°F (132 – 154°C) under load |

| Melting Point | ~ 320°F (160°C) |

| Specific Heat Capacity | 1.17 – 1.20 J/g·K |

| Flammability | Self-extinguishing, UL94 V-0/V-2 rated |

| UV Resistance | Excellent resistance to UV rays |

| Chemical Resistance | Resistant to acids, bases, and many organic solvents |

| Electrical Insulation | Excellent electrical insulator |

| Machinability | Easily machined, drilled, sawed, and thermoformed |

| Environmental Impact | Recyclable, but requires specific recycling processes |

Laser Cut For Polycarbonate – Laser Cutting PC Parts Service

Be-Cu Prototype is now offering complete Laser PC Cutting And Polycarbonate Precision Cut Service.

Be-Cu.com

Polycarbonate’s high melting point requires careful calibration of laser parameters to avoid excessive heat, which might lead to discoloration or melting beyond the intended cutting area.Be-Cu Prototype cut polycarbonate in black or clear sheet and plate. Its clarity, shatter-resistance, and lighter weight make it an excellent replacement for glass. It also handles high temperatures better than acrylic. Laser Cutting in polycarbonate does not inherently yield optically transparent parts, however, so some further finishing is required.

Laser cutting enables the creation of intricate patterns and complex shapes with remarkable precision, allowing designers to achieve detailed and intricate designs that would be challenging with conventional methods.Be-Cu provides not just laser cut pc parts service but also hybridized services leveraging prototype fabrication and additive manufacturing. Need plastics prototype fabrication as part of a more complex project? WE can handle it. Be-Cu has equipment dedicated to rapid prototype fabrication, including lasers, waterjet machines, finishing tools, autodeburring, 4 slide machines, multi-slide machines, press brakes, 300-ton presses, 22-ton presses, wire EDM machines, seely slide forming tools and 35-ton blanking presses.Do you need an estimate on an upcoming pc laser cut project? Get a fast quote on any 3d file.

The Application Of Polycarbonate Laser Cut

Polycarbonate, renowned for its exceptional durability, transparency, and versatility, finds numerous applications in various industries, and laser cutting has significantly expanded its potential uses. The precision and adaptability of laser cutting technology have revolutionized the way polycarbonate is utilized across different fields. Here are some notable applications of polycarbonate laser cutting:

Prototyping and Product Development

Customized Products: It facilitates the creation of custom-designed parts and components for diverse products, from electronic enclosures to automotive prototypes.

Electronics and Displays

Display Panels: Laser-cut polycarbonate sheets are used for creating transparent screens and display panels, especially in devices requiring impact resistance and optical clarity.

Signage and Advertisement

Point-of-Purchase Displays: Its versatility in shaping allows for eye-catching and unique point-of-purchase displays in retail settings.

Automotive Industry

Prototyping and Custom Parts: Laser cutting assists in producing customized and prototype automotive parts quickly and accurately.

Safety Equipment and Construction

Construction Components: Laser-cut polycarbonate finds applications in creating structural components like skylights, roofing, and windows due to its durability and weather resistance.

Art and Design

Architectural Design: It is used in architectural models and designs due to its ability to achieve intricate details and precise cuts.

Polycarbonate’s compatibility with laser cutting technology has opened up a world of possibilities across industries, offering a combination of strength, optical clarity, and design flexibility. As laser technology continues to advance, the applications of laser-cut polycarbonate will likely expand even further, pushing the boundaries of what’s achievable in manufacturing and design.

Benefits Of Laser Cutting PC

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of cut materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient Laser Cut factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience

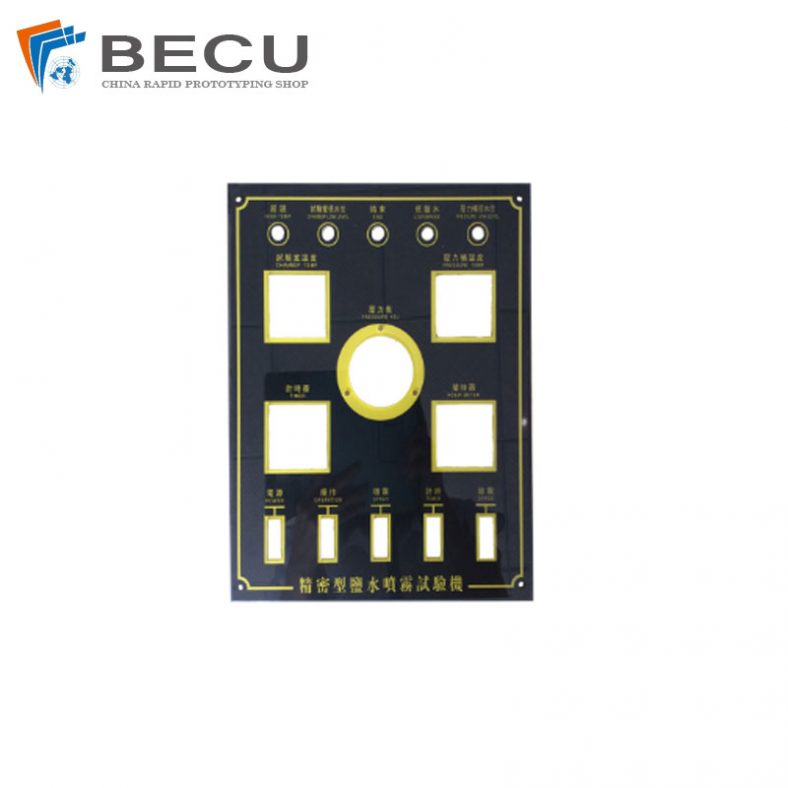

Custom Laser Cutting PC Projects & Parts Case Studies

Using our top of the PC laser cut service allows us to create unique design and features.We provide custom precision cutting services for a wide range of Polycarbonate. Using our high speed Polycarbonate laser cutter allows us to complete projects in a minimal amount of time while providing precision cuts and high yields limiting material waste.Check out our extensive gallery that shows precision Polycarbonate laser cutting prototypes and parts from our valued customers.