Cnc Machining Tool Steel : Enhancing Precision and Performance

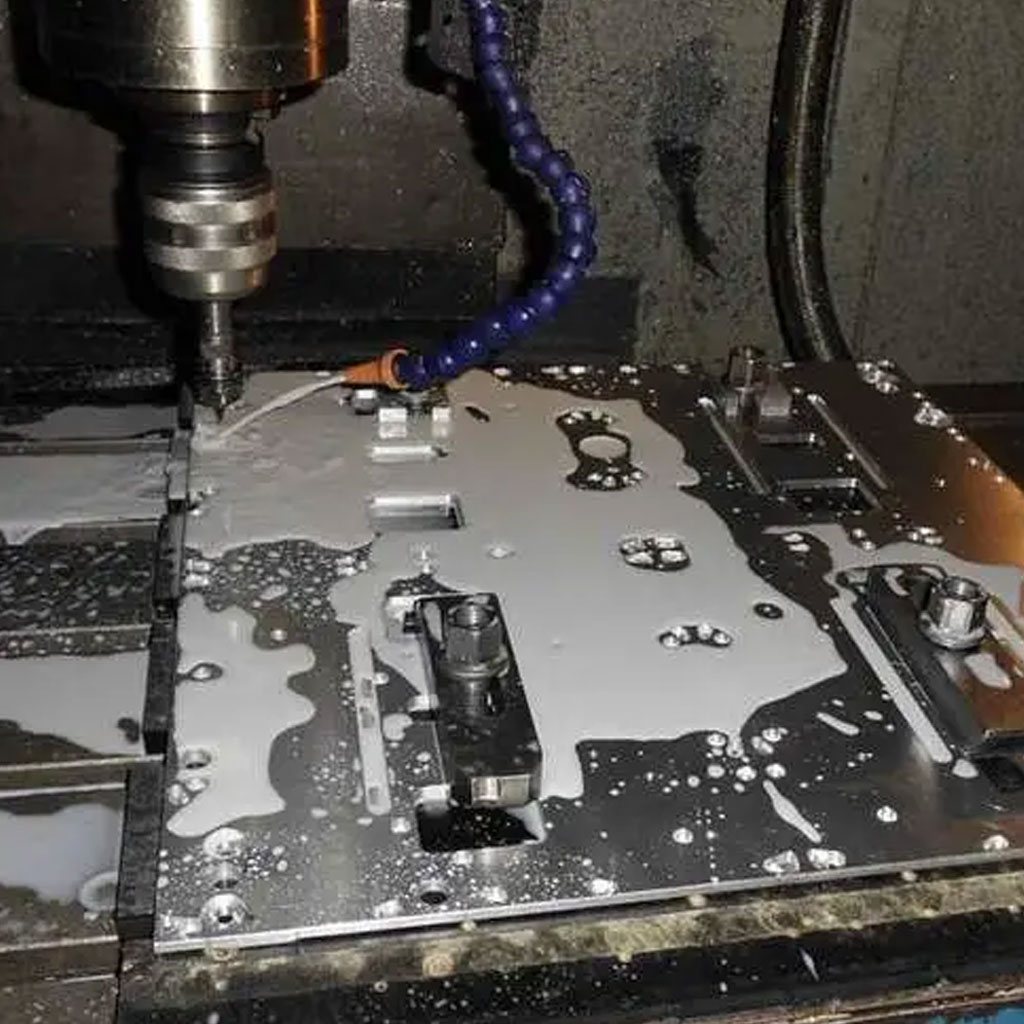

CNC machining has revolutionized the manufacturing industry, offering precise and efficient solutions for a wide range of materials.CNC machining of tool steel refers to the process of using computer numerical control (CNC) machines to shape, cut, and finish tool steel components. One such material that plays a critical role in tooling and machinery is tool steel. Tool steel is renowned for its exceptional hardness, toughness, and wear resistance, making it ideal for various applications, CNC machining provides precise and efficient control over the machining process, allowing for the production of complex geometries and high-precision components. Whether it’s producing molds, dies, or high-performance cutting tools, CNC machining of tool steel offers the accuracy and reliability needed for demanding applications.

The Composition Of Tool Steel

- Carbon (C):0.7% to 1.5%

- Tungsten (W):1% to 20%.

- Chromium (Cr):3% to 12%.

- Vanadium (V):0.5% to 5%.

- Molybdenum (Mo):0.3% to 10%.

- Cobalt (Co):1% to 30%.

- Nickel (Ni):0.5% to 4%.

- Manganese (Mn):0.2% to 2%.

At Be-Cu,our manufacturing team has mastered the technical challenges of machining large tool steel components to produce an uninterrupted reliable parts supply for our customers,to meet the client’s requirements with advanced technology.

While working with us, you don’t have to worry about the precision, accuracy, or quality of the products. You will get the best with Be-Cu.

Cnc Machining Tool Steel Services

Tool steel machining is widely utilized in industries such as aerospace, automotive, tool and die making, mold making, and many others. The benefits of tool steel machining, including hardness, dimensional accuracy, versatility, efficiency, and cost-effectiveness, make it an indispensable process for producing high-quality components that meet the demands of challenging applications.

At Be-Cu.com, we have dedicated experts that can handle all of your Tool Steel CNC machining services. We can assure the precision, quality, and affordability of your project components. Specifically, we handle CNC tool steel milling, turning, grinding,heat treatment,surface treatment, EDM, and wire EDM.

| Grades | Conditions | Forms |

|---|---|---|

| H-13 | Annealed/heat treated | castings, forgings, bar stock |

| A-2 | Annealed/heat treated | castings, forgings, bar stock |

| D-2/ D-3/ D-5 | Annealed/heat treated | castings, forgings, bar stock |

| Rex 76/ M2/ M4 | Annealed/heat treated | castings, forgings, bar stock |

| S-5/S-7 | Annealed/heat treated | castings, forgings, bar stock |

Tool Steel Machining Experts

Customers turn to Be-Cu for three important advantages that maximize adherence to tight tolerances while keeping tool steel machining costs fully under control.

- The exceptional precision of Be-Cu equipment, including DMU 5 Axis Machine,CNC Swiss machines, multi spindle cam automatics and CNC turning centers, interfaced with an Fanuc CAD/CAM system for precise conformity to the most elaborate geometries (equipment list)

- An in-house tool making facility that allows greater customization of tooling to the tool steel in use

- The eyes and hands of experienced machining craftsmen, who are skilled at spotting potential problem before they find their way into a production run

You can contact us by requesting a quote for any Tool Steel manufacturing process. One of our project managers will review your application and get a quote and DFM feedback for you within 12 business hours.

Why Choose Our Tool Steel Cnc Machining Service?

- Save time and money for your Steel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of steel grades and alloy materials can be machined

- Custom complex steel cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Tool Steel CNC Machined Parts

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make CNC Tool Steel prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes laser cutting is the only option. Our company has rich experience making Tool Steel concept models and precise functional components. Understanding the properties of different steel alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on tool steel alloy. Be-cu prototyping company provides a range of solutions for the machining of steel parts.

Overview Of Tool Steel – What Is Tool Steel

Tool steel is a type of specialty steel that is specifically designed for the production of tools, dies, and other cutting or shaping instruments. It is renowned for its exceptional hardness, toughness, wear resistance, and heat resistance. Tool steel’s hardness, wear resistance, toughness, and heat resistance are achieved through specific alloying elements and heat treatment processes,Its unique properties make it well-suited for the production of tool and die making, mold making, machining, and various industries where high-performance cutting tools are required.

Advantages of CNC Tool Steel Machining

- High Precision

- Improved surface finish and dimensional tolerances

- Consistency and repeatability

- Ability to produce complex geometries

- Increased productivity and efficiency

- Cost-effectiveness in large-scale production

The Applications Of CNC Machining Tool Steel

CNC machining of tool steel finds extensive applications in various industries where high-performance, precise, and durable components are required. Here are some common applications of CNC machining tool steel:

Cutting Tools

Dies and Molds

Forming Tools

Jigs and Fixtures

Wear Components

Tooling for Woodworking and Plastics

CNC machining tool steel is also employed in the production of various specialty components. These include precision shafts, gears, bearings, valve components, surgical instruments, and firearm parts. The high strength, hardness, and dimensional accuracy of tool steel ensure optimal performance, reliability, and longevity in these specialized applications.

The applications mentioned above represent just a few examples of the extensive use of CNC machining tool steel. The versatility, durability, and exceptional properties of tool steel make it a preferred material for producing high-quality components across diverse industries requiring precision, performance, and reliability.

Online Cooperate With CNC Tool Steel Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.