What is Steel & What is it Used for

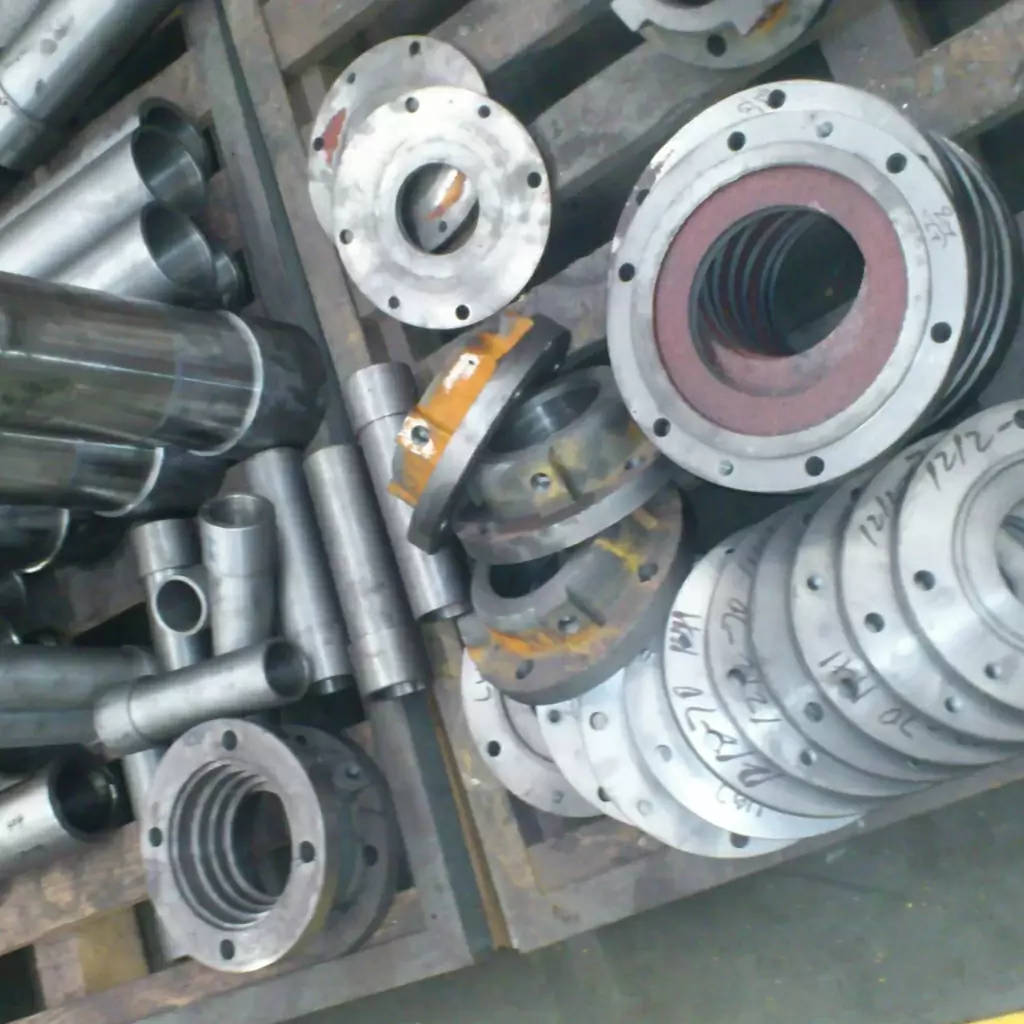

Steel comes in many forms: sheet metal in various geometries, plates, bars and beams, pipes, and of course the solid raw materials used in CNC machining steel. Steel is used in so many applications and in so many industries that it makes sense to have many different types of steel.

What is steel: Steel is a broad term for iron and carbon alloys. The carbon content (0.05%–2% by weight) and the addition of other elements determine the specific alloy of the steel and its material properties. Other alloying elements include manganese, silicon, phosphorus, sulfur and oxygen. Carbon increases the hardness of the steel and strength, while other elements can be added to improve corrosion resistance or machinability. Manganese is also typically high (at least 0.30% to 1.5%) to reduce the brittleness of the steel and increase its strength.

The strength and hardness of steel is one of its most sought-after properties. It is they that make steel suitable for construction and transportation applications, as the material can be used for a long time under heavy and repeated loads. Some steel alloys, the stainless steel varieties, are resistant to corrosion, which makes them the best choice for parts that work in extreme environments.

However, this strength and hardness also prolongs machining time and increases tool wear. Steel is a high-density material, which makes it too heavy for some applications. However, steel has a high strength-to-weight ratio, which is why it is one of the most commonly used metals in manufacturing.

The Type Of Steel

Let’s discuss the many types of steel. As steel, carbon must be added to iron. However, the amount of carbon will vary, which can lead to large variations in its properties. Carbon steel generally refers to steel other than stainless steel and is identified by a 4-digit grade of steel, more broadly mild steel, medium carbon steel or high carbon steel.

- Mild steel: less than 0.30% carbon by weight

- Medium carbon steel: 0.3–0.5% carbon

- High carbon steel: 0.6% and above

The major alloying elements of steel are indicated by the first digit of the four-digit scale. For example, any 1xxx steel, like 1018, will have carbon as the main alloying element. 1018 steel contains 0.14–0.20% carbon and small amounts of phosphorus, sulfur, and manganese. This general purpose alloy is commonly used to machine spacers, shafts, gears and pins.

Easy-to-machine grades of carbon steel are re-phosphated and re-phosphated to break the chips into smaller pieces. This prevents long or large chips from tangling with the tool when cutting. Free-machining steels can speed up processing times, but may reduce ductility and impact resistance.

Steel Machining Service – Custom Steel Cnc Machining Parts

Looking for reliable, quick-turn steel machining services suppliers and CNC Machined product manufacturers?

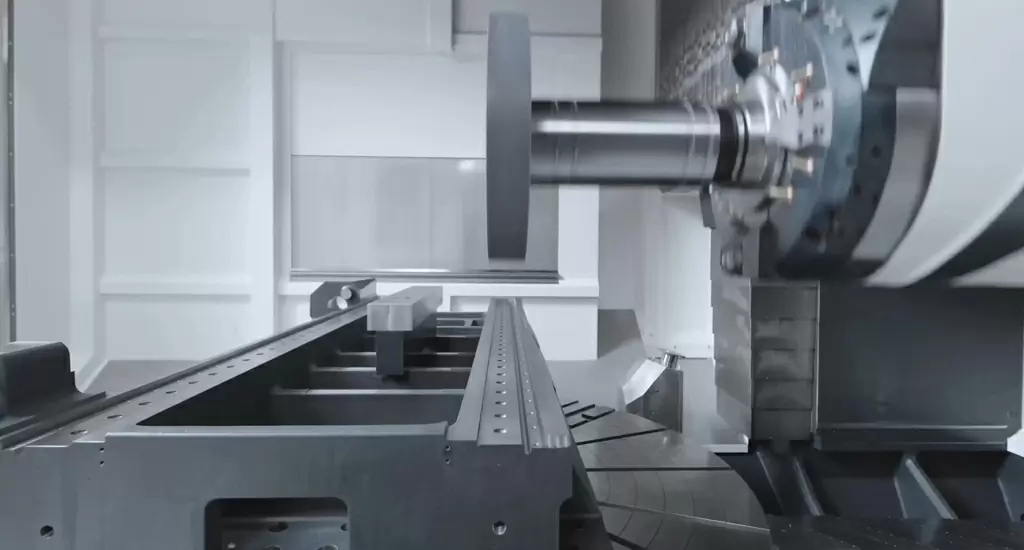

Simple shapes might be machined following a normalizing treatment, whereas more complex shapes will require annealing. At the carbon level of this grade, a structure of coarse lamellar pearlite to coarse spheroidite is normally optimum for machinability. BE-CU has the experience, knowledge, and CNC equipment required to machine steel. Our custom design and manufacturing services means you receive a unique solution to your complex component problems. Steel alloy grade is widely used for many general purpose parts requiring high tensile strength and toughness.BE-CU Prototype is a complete cnc machine shop capable of machining steel parts to customer specification (conventional machining,5 axis machining,wire cutting and more).

We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files. If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom machined parts.

Why Choose Our Steel Cnc Machining Service?

- Save time and money for your steel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of steel aqlloy grades and alloy materials can be machined

- Custom complex steel machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Steel Cnc Machining Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make Steel prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making Steel concept models and precise functional components. Understanding the properties of different titanium alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on titanium alloy. Be-cu prototyping company provides a range of solutions for the machining of Steel Parts.

-

High-Speed Steel (HSS) Die Punching Needles

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

Non-Standard Position Component For Mold

-

Standard Position Limiting Clamp For Plastic Mold

-

OEM Tool Steel Propeller Rope Guard Cutters

-

Custom Precision QKG Quick Action Vise

-

EDM Wire Cutting And Milling Machining 45# Steel Parts

-

Fast Silk Wire Cutting And Cnc Milling Steel Parts

-

Wire Cutting And 5 Axis Machining 45# Carbon Steel Parts

-

Cnc Machining And Wire Cutting S45C Steel Parts

-

45# Carbon Steel Parts By Precision Cnc Machining

The Handling Method Of Steel Alloy

Some of the most useful properties of steel come from additional processing and machining steps. These methods can be performed prior to machining to alter the properties of the steel, making it easier to machine. Keep in mind that hardening the material before machining increases machining time and increases tool wear, but steel can be treated after cnc machining to increase the strength or hardness of the finished product. That said, it is important to anticipate any planned treatments that you need to apply in order to achieve the necessary properties for your parts.

The Heat Treatment Of Steel Alloys

Heat treatment refers to several different processes that involve manipulating the temperature of steel to alter its material properties. An example is annealing, which is used to reduce hardness and increase ductility, making steel easier to work. The annealing process slowly heats the steel to the desired temperature and holds it for a period of time. The time and temperature required depend on the specific alloy and decrease with increasing carbon content. Finally, the metal is slowly cooled in a furnace or surrounded by insulating material.

Normalizing heat treatment removes internal stresses in the steel while maintaining higher strength and hardness than annealed steel. During normalizing, the steel is heated to a high temperature and then air-cooled for higher hardness.Hardening steel is another heat treatment process that, you guessed it, hardens the steel. It also adds strength, but also makes the material more brittle. The hardening process involves slowly heating the steel, soaking it at high temperature, and then immersing the steel in a water, oil or salt solution to cool it quickly.

Finally, a tempering heat treatment process is used to reduce the brittleness of the hardened steel. Tempering steel is almost identical to normalizing: slowly heat it to a selected temperature, then air cool the steel. The difference is that the tempering temperature is lower than other processes, which reduces the brittleness and hardness of the tempered steel.

The Precipitation Hardening Of Steel Alloys

Precipitation hardening increases the yield strength of steel. Some grades of stainless steel may have a pH value in their designation, which means they have precipitation hardening properties. The main difference between precipitation hardening steels is that they contain additional elements: copper, aluminum, phosphorus or titanium. There are many different alloys here. To activate the precipitation hardening properties, the steel is formed into its final shape and then age hardened. The age-hardening process heats the material for an extended period of time, causing the added elements to precipitate and form solid particles of different sizes, thereby increasing the strength of the material.17-4PH (also known as 630 steel) is a common example of a stainless steel precipitation hardening grade.

The alloy contains 17% chromium and 4% nickel, and 4% copper, which aids precipitation hardening.Due to increased hardness, strength and high corrosion resistance, 17-4PH is used in helideck platforms, turbine blades and nuclear waste barrels.

The Cold Working Of Steel Alloys

The properties of steel can also be changed without applying a lot of heat. For example, cold-worked steel is made stronger through the process of work hardening. Work hardening occurs when a metal is plastically deformed. This can be achieved by hammering, rolling or drawing the metal. Work hardening can also occur unexpectedly if the tool or workpiece overheats during machining. Cold working also improves the machinability of the steel. Mild steel is very suitable for cold working.

Steel Structure Design Considerations

When designing steel parts, it is important to keep in mind the unique properties of the material. Features that make it a good fit for your application may require additional Design for Manufacturing (DFM) considerations.

Due to the hardness of the material, machining steel takes longer than other softer materials such as aluminum machining or brass machining. You need to use the correct machine settings to optimize machining quality and minimize tool wear. In practice, this means slower spindle speeds and feeds to protect your parts and molds.