Turning Inconel

CNC (Computer Numerical Control) turning is a crucial machining process used across various industries to produce intricate and high-precision components.

One of the most challenging materials to machine is Inconel, a family of nickel-chromium-based superalloys known for their exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. These properties make Inconel an ideal material for critical applications in the aerospace, automotive, and energy sectors, but they also present significant challenges during machining.

Inconel alloys, such as Inconel 718, 625, and 600, are widely used in manufacturing components that must endure harsh environments, such as gas turbine blades, engine components, and nuclear reactors. However, the same properties that make Inconel desirable for such applications—high strength, toughness, and heat resistance—also make it one of the most difficult materials to machine using conventional methods. The machining of Inconel requires specialized tools, techniques, and strategies to achieve the desired precision and surface finish while minimizing tool wear and production costs.

CNC Turning Inconel Service – Custom Inconel Alloy CNC Turning

Looking for reliable, quick-turn Cnc Turning Inconel service suppliers and CNC turning product manufacturers?

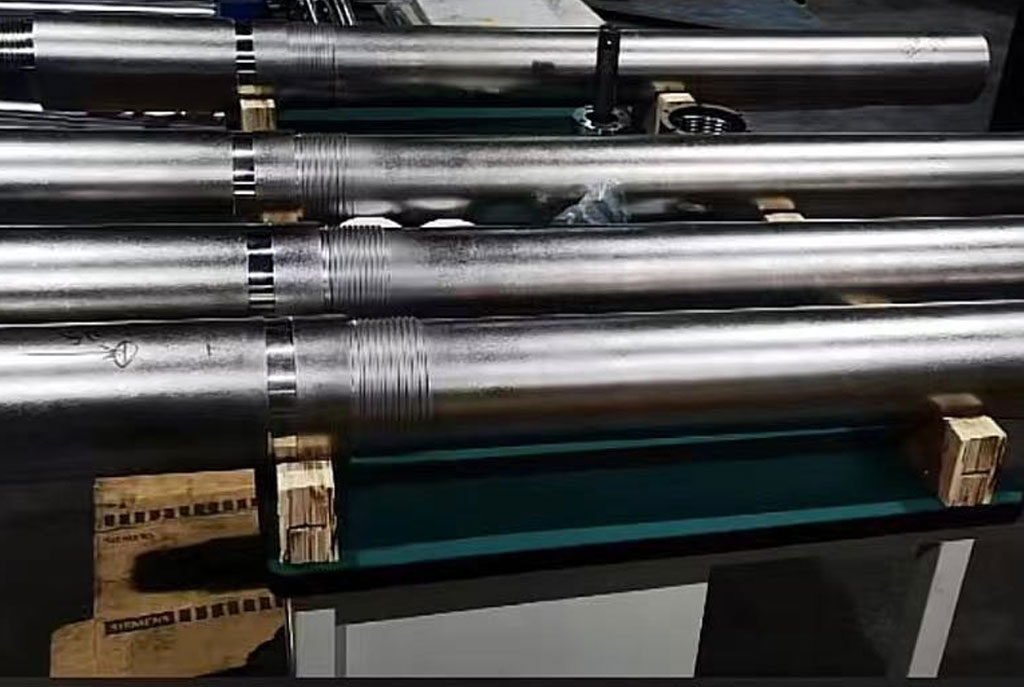

Long CNC turning services for Inconel. Turning can be done in +/-0.001 in. straight tolerance, +/-0.0003 in. concentricity tolerance and +/-0.0005 in. inner and outer dia. tolerance. Inconel Machining can be done with parts up to 72 in. dia., up to 168 in.(4m) length, up to 72 in. width and up to 72 in. height. Prototype and low to high volume production offered. Serves the automotive, aerospace, marine, medical, energy and other industries. Capabilities also include knurling, gear hobbing, drilling, boring, turning, forming, broaching, counterboring, parting/cutting, facing, threading, tapping, thread milling, lean manufacturing, high, low volume, large and small run production and prototyping.

Turning Inconel 625

Inconel 625 is a non-magnetic, corrosion-resistant, and oxidation-resistant nickel-chromium alloy. The high strength of Inconel 625 is derived from the hardening effect of molybdenum and niobium on the nickel-chromium matrix of the alloy. Inconel 625 exhibits excellent resistance to a wide range of unusually severe corrosive environments, including high-temperature effects such as oxidation and carburization, as well as general corrosion. Its outstanding strength and toughness over a wide temperature range, from cryogenic to up to 2000°F (1093°C), primarily come from the solid solution strengthening of refractory metals like cobalt in the nickel-chromium matrix.

Nickel-chromium alloy 625 possesses excellent resistance to pitting and crevice corrosion, high corrosion fatigue strength, high tensile strength, and resistance to chloride ion-induced stress corrosion cracking, making it an ideal choice for seawater applications. This chromium-nickel-iron alloy is used in aerospace and marine applications.At BE-CU, we specialize in creating high-quality inconel 625 turning parts, including oil and gas shaft, heat exchangers, and heat sinks components & parts.

Turning Inconel 718

Nickel-based alloys hold a particularly important position in the field of high-temperature alloys, widely used in the manufacturing of the hottest end components of aerospace jet engines and various industrial gas turbines. Among nickel-based superalloys, Inconel 718 is the most widely used and is considered a typical difficult-to-machine material. During machining, issues such as high cutting forces, elevated cutting temperatures, significant work hardening tendency, and severe tool wear are commonly encountered. With the widespread adoption of high-speed cutting technology, the high-speed machining of nickel-based superalloys has become a hot topic of research both domestically and internationally in recent years.

Every inconel 718 turned component, including the most intricate high-volume production run, benefits from the presence of skillful, knowledgeable CNC turning inconel industry professionals. Our staff of engineers, materials experts, and experienced craftsmen are on call to make sure BE-CU.com’s customers have total confidence in their source of supply.

Why Choose Our Inconel Cnc Turning Service?

- Save time and money for your Inconel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of inconel grades and alloy materials can be machined

- Custom complex Inconel machined parts and components at specific tolerances

- High speed cnc turning for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Inconel Cnc Turning Parts and Case Studies

Cnc Turning processes such as precision turning and large cnc turning are today considered the most economic way to make titanium prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making inconel Concept models and precise functional components. Understanding the properties of different inconel alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on inconel alloy. Be-cu prototyping company provides a range of solutions for the turning of inconel parts.