China Top High Pressure Die Casting Services

Various customers and OEM’s who need high-volume die casting services have confidence in Be-cu Prototype for on-time delivery of their advanced manufactured parts. Our commitment to using superior high pressure die casting equipment, backed by our dedication and decades of experience, is what sets the production professionals at BE-CU apart from the competition.

Why BE-CU Die Casting Services?

- Productivity – Today’s BE-CU die casting machine produce products from metal material using up to 3000T of pressure. 20+ Die Casting Machines create cost efficient small parts in both large and small volumes. For more information, see our complete equipment list.

- Field Verification – Our company features a 30,000m2 manufacturing plant, and 200 experienced engineers & support staff. In addition,BE-CU CEO owns 100% ownership for a powder spraying plant and a medium-sized CNC machining shop.

- Versatility – The Be-cu portfolio of Die Casting Services include components made of many die casting material types; including aluminum,zinc, magnesium, brass and other metals, to meet the specialized needs of customers in led,electronic, automotive, medical, appliance, food / beverage and more.

Top-Tier Die Casting Experts

Our die casting services can deliver quality parts with economic and smooth surface finish, most importantly, can perfectly match your requirements. From thin wall die casting to cold chamber die casting to hot chamber die casting, trust professional experts and engineers at Be-cu to help you in die casting, as well as other tooling manufacturing. We’ll minimize the downtime costs and improve the efficiency to provide a cost-effective solution with a short lead time.

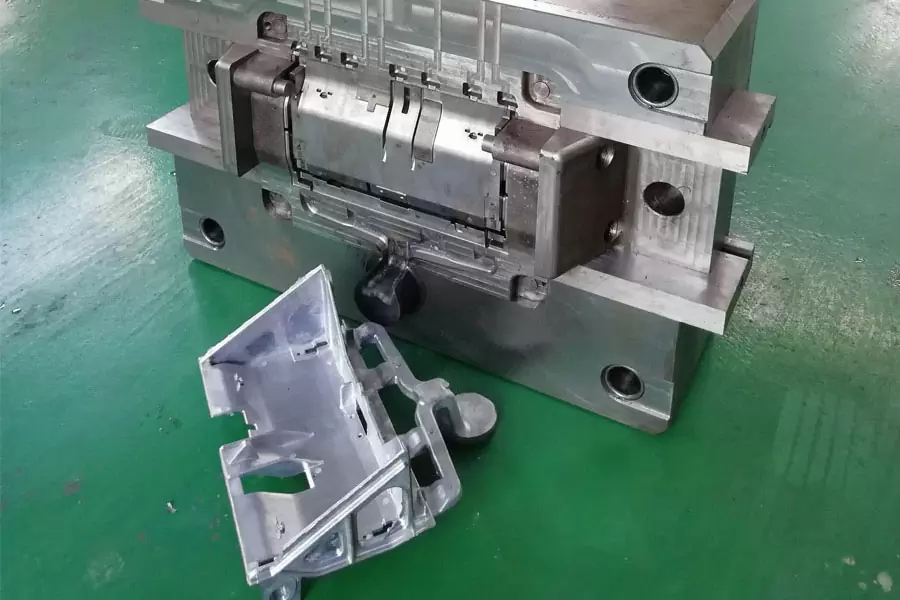

Die Casting Mold Manufacturing Experts

Be-cu meets or exceeds the quality standards of the world’s most demanding industries with our state of the art equipment and trained professionals. Our engineers offer design solutions for a variety of industries including consumer electronics, automotive, healthcare, and more. When our engineers are involved early in the project, they can help design a tool and part specifically for mass production.Fast to upload your CAD files or send us your inquiry to get a quick response online.

Die Casting Mold Making

- Step 1: Product DFM & Mold Design

- Step 2: Mold Steel and Other Accessories Purchase

- Step 3: CNC Machining

- Step 4: Heat Treatment

- Step 5: WireCutting/EDM/Milling/Drilling/

- Step 6: Mold Fitting, Assembly, and Trial

- Step 7: Refine, polish, and Texture

Be-cu Die Casting Process

- Upload Your Profiles

- Detail Consultation

- Drawing Design

- Mold Making

- Die Casting

- Friction welding

- Trimming

- Cnc Machining

- Drilling & Tapping

- Post Processing

- Deburring Surface

- Surface Treatment

- Final Inspection

- Assembly And Testing

- Packing And Shipping

- After Sales & Return

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

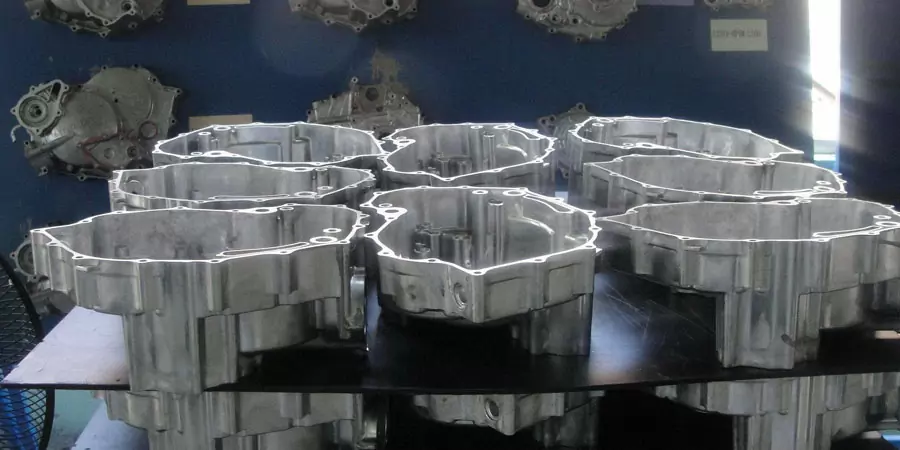

Top Metal Casting Services Capabilities

Aluminum High Pressure Die Casting is applied to molten cast aluminum in the mold cavity which is Similar to injection molding. Complex parts with sophisticated shapes can be made through aluminum die casting service. The precision die casting aluminum parts contains: Automobile engine block, rocker arm, carburetor, water pump housing, gearbox housing, clutch housing, steering housing and other parts of the production and more.

Zinc die casting is a kind of precision casting method, which uses high pressure to force the metal to melt into the complex metal mold.Be-cu is one of the most affordable and capable zinc parts manufacturer, specializing in high pressure casting process on advanced 200T and 1650T die casting machines.With great experience and broad knowledge, our zinc die casting center can reach extremely tight tolerances in manufacturing zinc parts & products.

Magnesium Alloy Die Casting is a kind of magnesium alloy based on magnesium and alloying elements, which is suitable for casting parts.Be-cu have over 10 years of magnesium die casting experience, have capabilities to manufacture simple or complex magnesium products including precision die casting components, thin wall and high pressure die casting magnesium parts to meet your demands with reliable operators, sophisticated machinery and equipment at our disposal.

Custom china die casting service provides durable and affordable castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your die casting project.

Top Metal Casting Case Studies

You have a complex part design, Be-cu Die Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

CNC Machining Gas Stove Bottom Joint

-

Gravity Die Casting Custom Street Light Heat Sink

-

Die Casting LED Canopy Lights Heatsink For Gas Station

-

Zinc Die Casting PA10 Transformer Connector Terminal

-

Die Casting Aluminium Cookware Chassis

-

Die Casting Wheels With Aluminum Alloy 5 Axis CNC Machining

-

Precision Machined Copper Die Casting Parts

-

Professional Small Baler Aluminum Alloy Die-casting Mold Production

-

China Die Casting Factory Manufactures Surface Sprayed Aluminum Valve Body

-

Extrusion Die-casting Polyurethane-Coated Aluminum Alloy Profiles

-

Custom Precision Aluminum Die Cast Brackets and Finishes

-

Extrusion Die-casting Magnesium Alloy Heat Sink Shell