What Is Die Casting Heatsink

Die casting heatsink is a type of heatsink that is manufactured using the die-casting process. Heatsinks are components used to dissipate heat generated by electronic devices, such as computer processors, LEDs, power transistors, and other heat-sensitive components. Die casting heatsink is a heat-dissipating component manufactured using the die-casting process. It is designed to efficiently transfer heat away from electronic components and is commonly used in various industries to prevent overheating and ensure the reliable operation of electronics.

In today’s fast-paced world of electronics and computing, thermal management plays a pivotal role in ensuring the reliability and longevity of electronic components. One of the most crucial components in this realm is the heatsink, and recent advancements in manufacturing technology have led to the emergence of heatsink die casting as a game-changer.Die-casting heatsinks come in various shapes and sizes, tailored to the specific requirements of the application.With decades of years in the led light heatsink oem industry, Be-Cu prototype’s heatsink die casting services can meet the needs of customers in the production of high-volume & low-cost heat sink.

Heatsink Die Casting Services On Demand

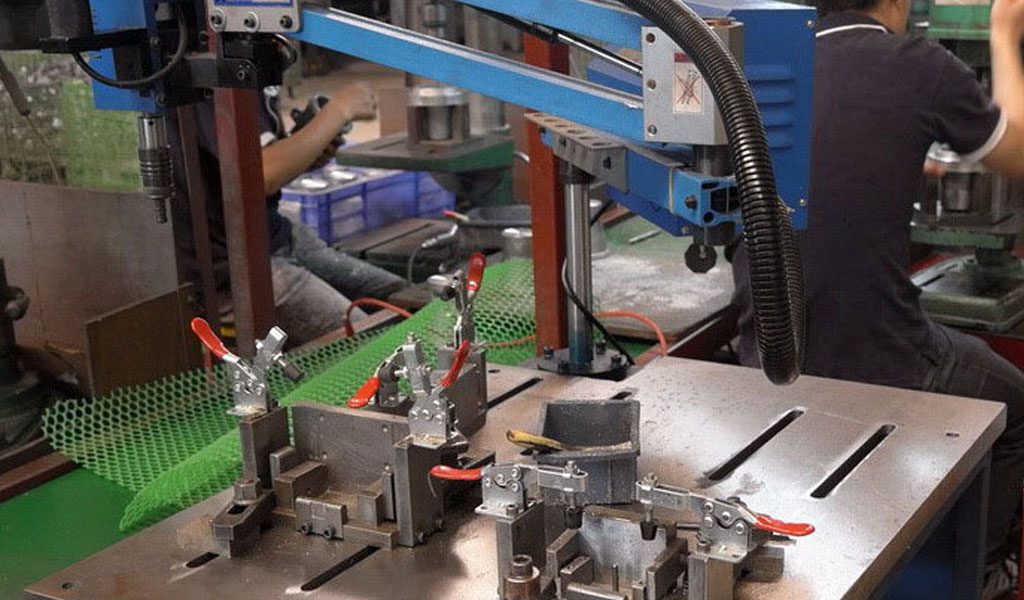

Be-Cu is Custom manufacturer of heat sink die castings.We have accomplished operators in the workshop to execute each operation in a correct way to ensure the products meet or exceed international standards and customer expectations. Capabilities include manufacturing aluminum die castings in machines ranging from 600 tons to 3000 tons & zinc die castings in machines ranging from 150 tons to 600 tons at various automations. Services include C-frame trim pressing, four-post trim pressing & secondary finishing including shot blasting & ball burnishing. Complete in-house tool & die shop also available.Strong, lightweight, and corrosion-resistant heatsink can be obtained through a fast and efficient die casting process. From quality to service, strict requirements and high standards help us gain a good reputation among worldwide clients.In some cases, die casting is a more cost-effective method than other heat sink manufacturing processes.

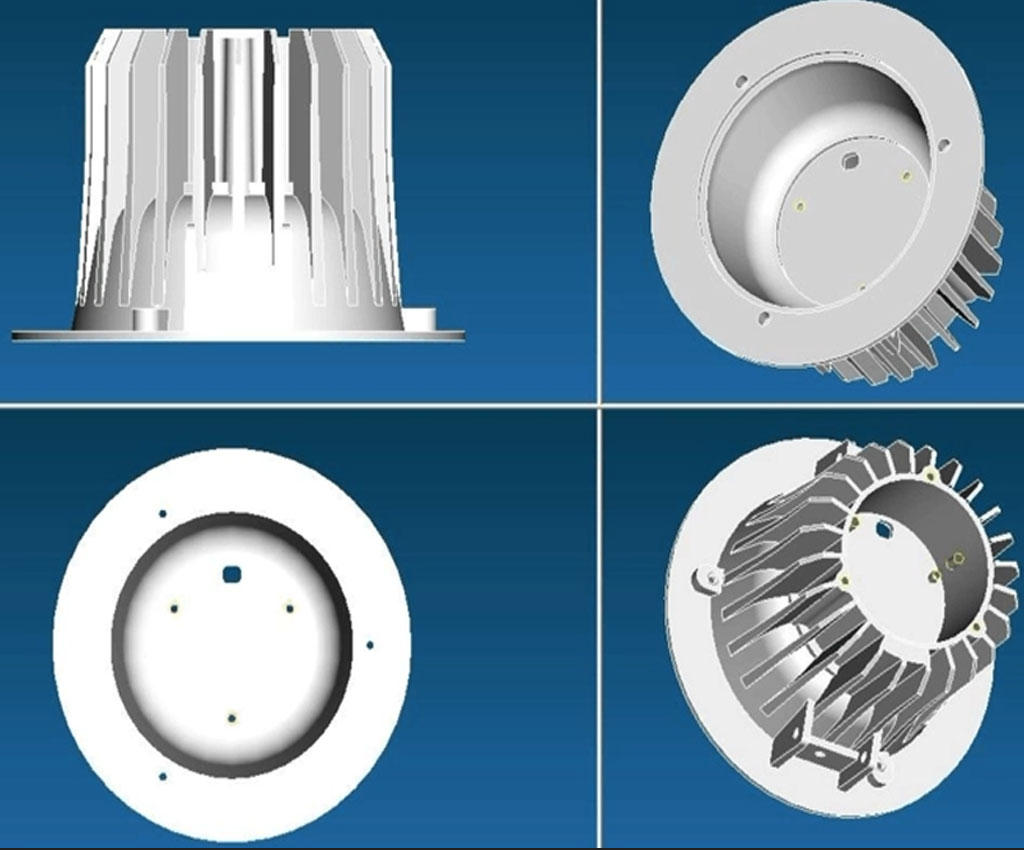

Tooling design

Tooling Fabrication

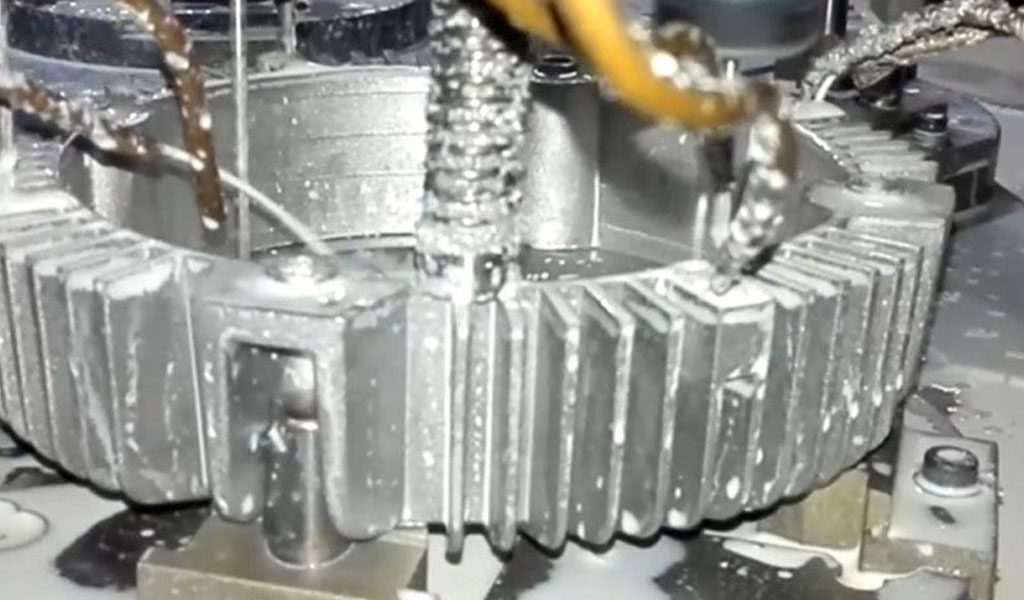

Heatsink Die Casting

Precision CNC Machining

Auto Threading

Sandblasting

Precision CNC Machining

Ultrasonic Eeaning Line

Automatic Cating

Export Carton

Heatsink Die Casting For LED Light

As one of the leading lighting parts manufacturers in China, Be-Cu can deliver the high-quality products for your specific lighting applications. We offer a comprehensive menu of die casting services for lighting parts for both outdoor and indoor use. All of our die casting lighting parts are backed by more than 30 years of experience in providing a wide range of die casting and related services to companies in all industries. You can trust us to develop the right lighting solution for your needs and budget. Here are some typical die cast aluminium lighting and die casting lighting parts.

- High Bay Light Heat Sink

- Street Light Heat Sink

- Flood Light Heat Sink

- Stadium Lights Heat Sink

- Stage Lights Heat Sink

- More Outdoor Light Heatsink

Benefits of Die Cast Heat Sinks

Compared with other manufacturing methods, die casting offers the following benefits:

- Efficient Heat Dissipation

- Excellent Thermal Conductivity

- Lightweight

- Complex Geometries

- Cost-Effective

- Consistency and Precision

- Rapid Production

- Environmental Benefits

- Longevity

Do not worry about the quality of our die casting led light heatsink. Let us assure you that we apply the most strict quality- assurance measures for the best possible results. We also provide other die casting heatsink like die casting automotive heatsink. Feel free to get in touch with our team for more information if you have any questions about die casting heatsink or need to work with specific alloys similar as aluminum. We ’ll also be happy to give any details about our die casting process.

Why Choose BE-CU Heatsink Die Casting Service?

- Modern and advanced casting equipment to ensure highest accuracy of die casting heatsink.

- Vacuum die casting machine in house

- Aluminium High Pressure Die Casting machines from 450 ton to 3000 ton,max weight :60kg (133pound)

- 50 set cnc machine for machined castings parts,metal, extrusion etc.

- Powder coating production line,CMM,X-ray in house

- Design and produce complex custom automotive parts

- Has strong and professional technical team and efficient management operation system and is equipped with advanced manufacturing equipment, ensure you can get best heatsink of die casting service.

Certifications & Quality List

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Product Description Of Our Heatsink Die Casting Services

Heatsink Die Casting Applications:

Heatsink die casting parts can be applied to Computer and Electronics, LED Light, Automotive Electronic, and more

Custom Colors:

Black, Natural, Blue, Green and different colors as your requirements

Surface Finishing:

Sand blasting, shot blasting, polishing, anodizing, oxidation, electrophoresis, chromate, powder coating and painting

Various Heatsink Die Casting Process:

Heatsink Thin Wall Die Casting,Heatsink Cold Chamber Die Casting, Heatsink Hot Chamber Die Casting

Recent Die Cast Heat Sink Projects

You have a complex part design, Be-cu Die Casting Company can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu ensure that every project is completed to a high standard and that your orders are delivered on time, every time.