Brass Sheet Metal Fabrication

Brass is an alloy of copper and zinc. Brass with different mechanical properties can be obtained by changing the content of zinc in brass. The higher the zinc content in brass, the higher its strength and slightly lower its plasticity. The zinc content of brass used in industry does not exceed 45%. The higher the zinc content is, the brittleness will occur, and the properties of the alloy will become worse. Adding 1% tin to brass can significantly improve its corrosion resistance to sea water and sea atmosphere, so it is called “naval brass”. Tin can improve the cutting and abrasive properties of brass.

The lead brass is commonly referred to as the easy cutting national standard copper. The main purpose of adding lead is to improve the cutting and processing properties and improve the resistance. The strength of lead on brass is not large. Engraving copper is also a kind of lead brass. Most brass has good color, processability, ductility, and is easy to electroplating or coating.

Benefits of Brass In Sheet Metal Fabrication

Brass is formed by adding zinc to copper, with the exact amount of zinc dependent on the grade.All Brass have a high resistance to corrosion and heat making it a durable metal with a long lifespan.Brass is often able to withstand many years of use without showing signs of wear and tear. Other advantages include:

- High resistance to corrosion

- Easily cut, welded, formed, machined and fabricated readily

- Due to its strength, Brass can be used to reduce material thicknesses, reduce weight and costs

- 100% Recyclable

- Its unique hygienic properties makes it the first choice in hospitals, kitchens, food and pharmaceutical processing facilities

The Brass Alloy Grades Of Sheet Metal Fabrication

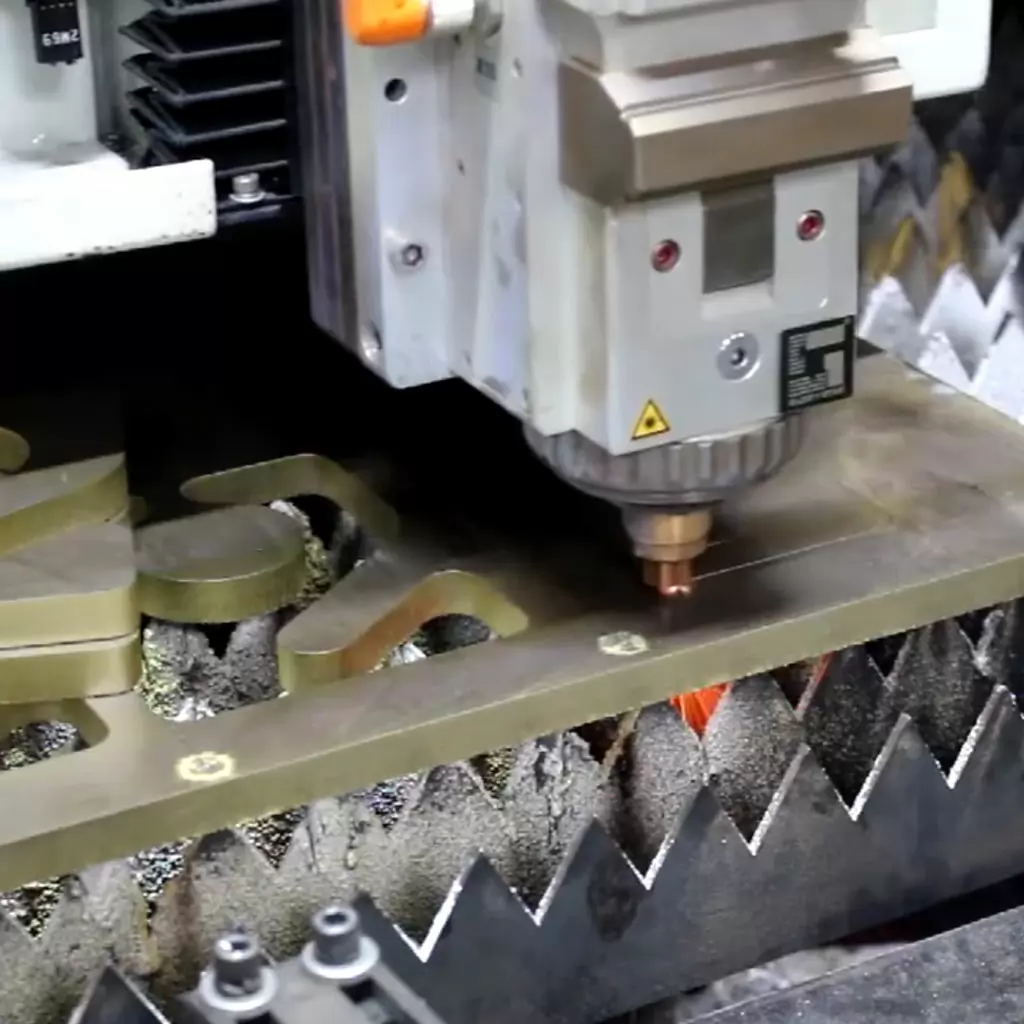

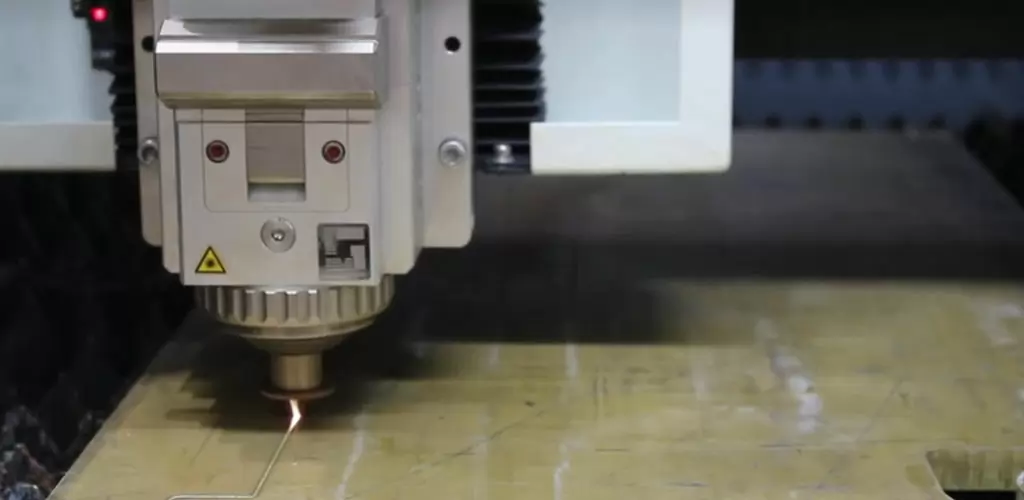

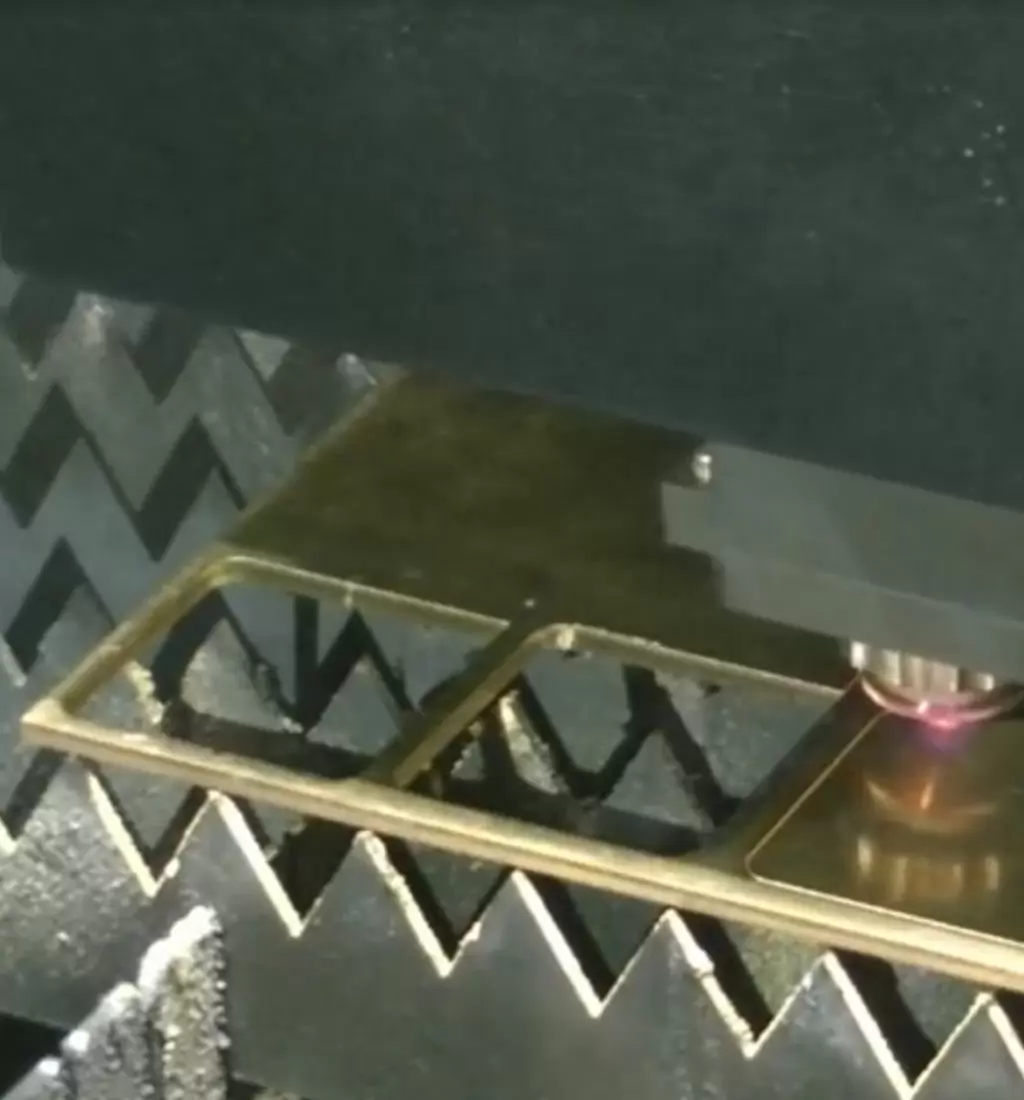

Brass uses higher laser power and auxiliary gas is air or oxygen, which can Sheet Metal thinner plates. Common brands: H59, H62, H70 and etc.,The grades of brass alloys are as follows:

| GB | UNS | BS | DIN |

|---|---|---|---|

| H68 | C26200 | CuZn33 | |

| H65 | C26800 | CZ107 | CuZn36 |

| H63 | C26800 | CuZn37 | |

| H62 | C27400 | CZ108 | CuZn37 |

| HPb63-3 | C34500 | CZ119 | CuZn36Pb1.5 |

| HPb60-2 | C36000 | ||

| HPb59-3 | CZ120 | ||

| HPb59-2 | C35300 | CuZn39Pb2 | |

| HPb59-1 | C37800 | CZ122 | CuZn39Pb3 |

| HPb58-2.5 | C38000 | CZ121 | CuZn |

Brass Sheet Metal Fabrication Services – Sheet Metal Manufacturing Brass Parts Suppliers & Manufacturer

Brass sheet metal is used to create reliable, precision parts for a wide range of industries, including automotive, medical, electronics and plumbing. At Be-cu.com, we spend a considerable amount of time understanding the brass and its properties. Our experts employ their material knowledge to sheet metal fabrication parts with high precision.

We have experience and expertise to deliver high-quality sheet metal fabrication brass parts in specified tolerances. Whatever your project needs, we can supply a solution.Our experts will work with you to understand your unique requirements before offering a solution.Our state-of-the-art machinery can produce hundreds to thousands of identical parts fast, and all of our parts must pass a thorough ISO 9001:2015 compliant inspection before shipping. So, you can contact us today to know more about brass sheet metal fabrication capabilities. We will be happy to assist you.

Precision fabrication services including brass and brass alloy. Capable of forming parts from 12 in. to 90 ft. length, 0.015 to 0.125 in. material thickness and +/-0.005 in. tolerance. Large run and low to high volume production runs available. Suitable for conveyor covers, frocking tanks, support panels, trailer walls, railcars, boiler plants, trailers, awnings and flare fences. Serves the aerospace, architectural, construction, marine, military, mining, transportation and power plant industries.

If you need precision brass sheet metal fabrication, call the experts at Be-Cu prototype today, or email us at [email protected].

Why Use Our Brass Sheet Metal Fabrication Services

Be-cu.com is one of the reliable precision sheet metal Brass parts manufacturer in the China. Our years professional sheet metal equipment provide you all-around care services that our experienced project engineers and machinists will analyze your project carefully and process it with the most efficient process of sheet metal fabrication brass to to meet your design specification, while optimize your time and cost.The Top 6 Reasons:

- No MOQ:One-off brass laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom brass laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Our Capabilities And Case Studies Gallery Of Brass Sheet Metal Fabrication

At Be-cu.com, we are highly experienced in manufacturing custom brass sheet metal parts for demanding applications. By providing a cost-effective fabrication service that doesn’t sacrifice precision or quality, we benefit our customers by making their design ideas for crucial parts and project components become a reality.For more case studies about our services, see the products list below and contact us directly.