Grinding And Laser Cutting Carbon Fiber Service In China

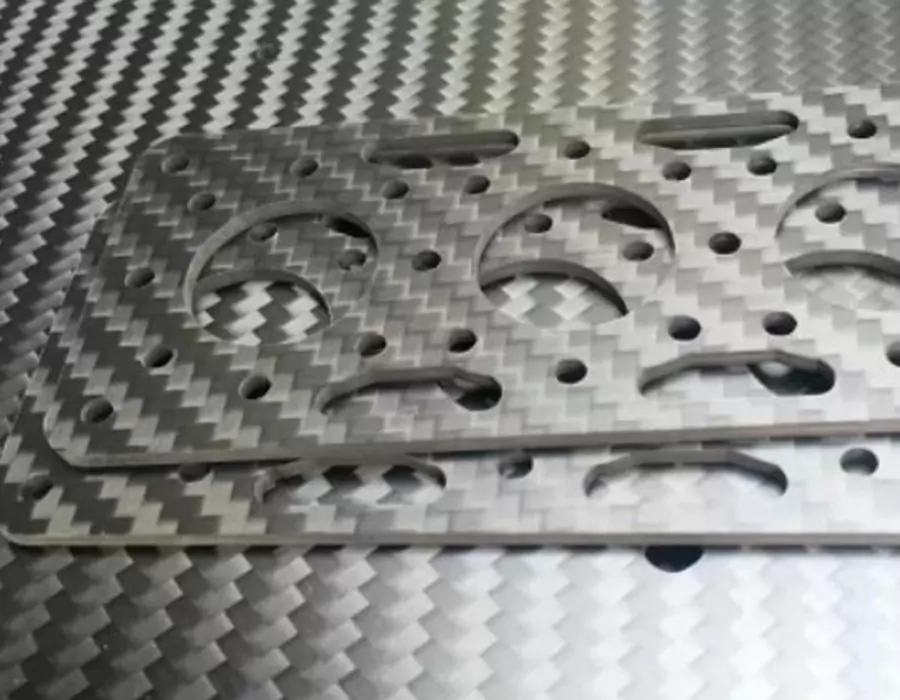

As one professional Grinding And Laser Cutting services manufacturers in China, BE-CU can machine all kinds of low cost carbon fiber materials parts. One of the most popular engineering material – carbon fiber Grinding And Laser Cutting part will not be ignored. Be-cu customizes precision CNC carbon fiber parts according to customer specifications, samples or drawings. Our Grinding And Laser Cutting carbon fiber precision parts can undertake surface spraying, electroplating, metal welding, hot pressing and adhesion, widely used in machinery, automobile, electronic appliances, instruments and meters, textile and construction industries. Our technicians have me many years experience and knowledge in Grinding And Laser Cutting exceptional quality carbon fiber precision parts.

Aerospace, shipbuilding and other fields have extremely strict requirements on the laser cutting accuracy of carbon fiber composite materials, and it is necessary to use grinding processing + laser cutting to achieve better surface quality. However, laser cutting carbon fiber composites is much more difficult than metal. The research shows that under the same cutting conditions, the cutting force increases linearly with the increase of grinding depth, and is greater than the cutting force when machining unidirectional carbon fiber composites. For the processing of unidirectional carbon fiber composite workpieces, the surface integrity of the product is greatly affected by the fiber direction.

Aiming at the problem that the traditional carbon fiber laser cutting process is prone to defects, it has been tested that the new process equipment of “cutting and drilling” can obtain higher machining accuracy and surface quality, which can meet the current industrial requirements for hole machining of carbon fiber workpieces.

Laser cutting + grinding of carbon fiber products using a cup-shaped grinding wheel, and cooling the product with a coolant inside.Results Surface: The built-in coolant laser cutting + grinding process can effectively grind carbon fibers, and the surface will not produce delamination and burrs. This method has a better cooling effect, can effectively reduce the grinding temperature, and is more conducive to the discharge of chips.

The Advantage Of Grinding And Laser Cutting Carbon Fiber

- ISO 9001:2015 certified and ITAF 16949 certified

- Fully compliant with the exacting requirements of our customers,High customer satisfaction and loyalty

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Skilled in KanBan and other customer driven quality and inventory management systems

- Efficient CNC machining factory for mass production rapid prototyping service

- Fast free quotation within 24 hours after inquiry

- Rich design and manufacturing experience