Laser Cutting For Electronic Parts

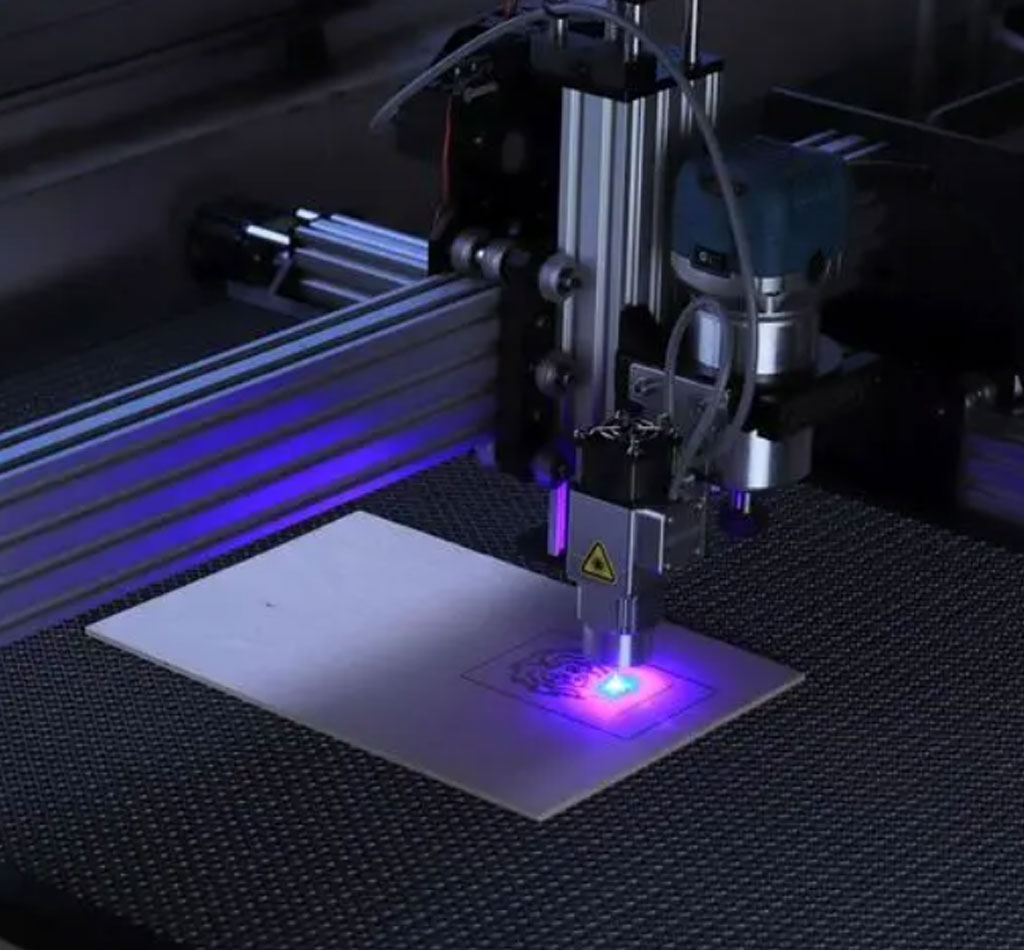

Laser cutting of electronic parts involves using a focused beam of light energy (a laser) to precisely cut, engrave, or mark various materials used in electronic components and devices. This technology is commonly used in the manufacturing of electronic parts due to its accuracy, speed, and versatility in working with various materials.Here’s how laser cutting is applied to electronic parts manufacturing:

- Precision Cutting: Laser cutting allows for extremely precise and clean cuts on materials such as metals (like aluminum, copper, and steel), plastics, ceramics, and even printed circuit boards (PCBs). This precision is crucial in creating intricate designs and shapes required for electronic components.

- PCB Manufacturing: In electronics, laser cutting is frequently used in PCB manufacturing. It helps in precisely cutting, drilling, and engraving PCBs to create conductive pathways, isolation gaps, and intricate patterns required for electronic circuits.

- Component Fabrication: Laser cutting is employed in shaping various electronic components, such as casings, enclosures, connectors, and even tiny components like microchips and sensors. It offers high accuracy in creating custom shapes and designs.

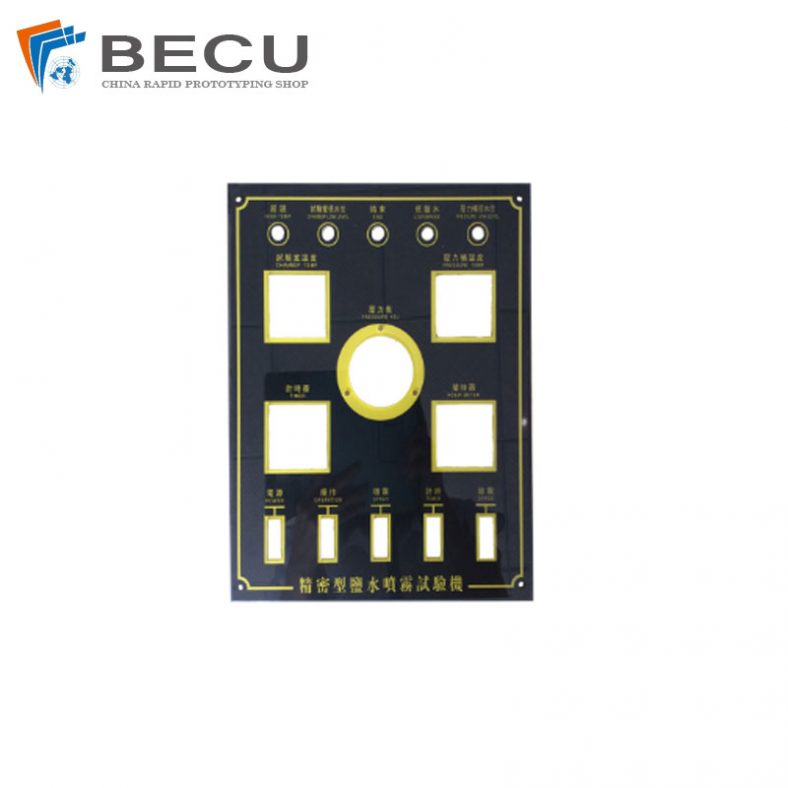

- Marking and Engraving: Apart from cutting, lasers are used for marking and engraving electronic parts for identification, branding, or adding serial numbers. This could be useful for traceability and quality control purposes.

- Material Versatility: Laser cutting can work with a wide range of materials, including metals, ceramics, glass, plastics, and even certain types of organic materials, allowing for flexibility in manufacturing various electronic components.

Laser cutting in electronics manufacturing provides several advantages, including high precision, minimal material wastage, automation capabilities, and the ability to create intricate designs that might be challenging or impossible using traditional cutting methods.

However, it’s important to note that while laser cutting is a powerful technology, it requires expertise to operate and must be handled with caution due to the high-intensity laser beam involved. Safety measures are crucial to prevent accidents and ensure proper functioning of the equipment.

Overall, laser cutting plays a vital role in the production of electronic parts, contributing to the efficiency and precision of manufacturing processes in the electronics industry.

Electronics Laser Cut Service – Precision Electronic Laser Cutting Parts

The laser cutting of parts for the electronics industry requires definite precision and experience to build a high-quality product to enhance the functioning of the end product. The make and break of an electronic machine depend on the perfection of these little parts. A slight difference in their manufacturing—and the whole final product can collapse.

Semiconductors, electronic and mechanical components, circuit boards, and any part that fits in an electronic assembly must be well designed and tested before sending out for application.

Be-Cu’s experts with many years of combined micro laser cut electronics experience use modern methods to manufacture complex electronic parts for electronic assembly support and various other functions in the electronics industry.

Whether you need a single prototype or many electronic parts , we promise to deliver quality every time.Be-Cu provides precision laser cutting for a wide range of electronics industry applications, from semiconductor manufacturing to computer technologies to robotics and much more. Our electronics parts and components consistently meet the tight tolerances required by this ever-growing industry. We use modern technology in our services

- Small Cutting Slit Width: 15~30um

- High Manufacturing Accuracy: ≤±10um

- Good Incision Quality: Smooth incision & small heat affected zone & few burrs

- Size Refinement: Minimum product size 50um

- With CMM Inspection, we make sure every part that leaves our place is perfect for your industry.

Our extensive experience and superior equipment enable us to turn even the most complex designs into tangible products. From prototypes and one-offs to full production runs with quantities in the tens of thousands, Be-Cu delivers top quality, high precision parts for customers in all sectors of the electronics industry. We can cut parts that match your design specifications exactly—quickly, efficiently, and with perfect repeatability.

Our Services

- Laser cutting of electronic parts from a variety of materials.

- Creation of intricate patterns, engravings, and perforations.

- Rapid prototyping for custom designs.

- Consultation and collaboration for design optimization.

Industries We Serve:

- Semiconductor Integrated Circuit

- Precision 3C structural parts

- LED Light Parts

- Medical Electonics

- More Electronics

When you choose Be-Cu as your electronics parts laser cut supplier, you’re choosing a partner dedicated to turning your visions into reality. With our blend of expertise, cutting-edge technology, and commitment to quality, we are poised to be your go-to solution for all your laser-cut electronic component needs. Illuminate your designs with precision, style, and innovation – choose Be-Cu today.

The Case Studies Of Electronic Parts Laser Cutting

You have a complex electronics design, Our Electronic Parts laser cutting service can help you turn it into a reality. With the right equipment, strong technical knowledge, and a focus on quality.. From tool design to finishing and then on to shipment, Be-cu prototpe ensure that every project is completed to a high standard and that your orders are delivered on time, every time.

-

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

3D Laser Cut And Drilling Stainless Steel Pipe

-

Tube Laser Cutting Iron Lighting Parts

-

Aluminum 7075 Laser Cutting Digital Accessories

-

Pipe Laser Cutting Aluminum Speaker Enclosure

-

Sheet Metal ATM Withdrawal Module Chassis Trunking Installation Parts

-

Sheet Metal Manufacturing 3D Printer Scanning Module Support Connecting Plate

-

Sheet Metal Fabrication Bank Self-Service Number Machine Side Slide Bracket

-

5G Outdoor Integrated Machine Connector Control Panel By Sheet Metal

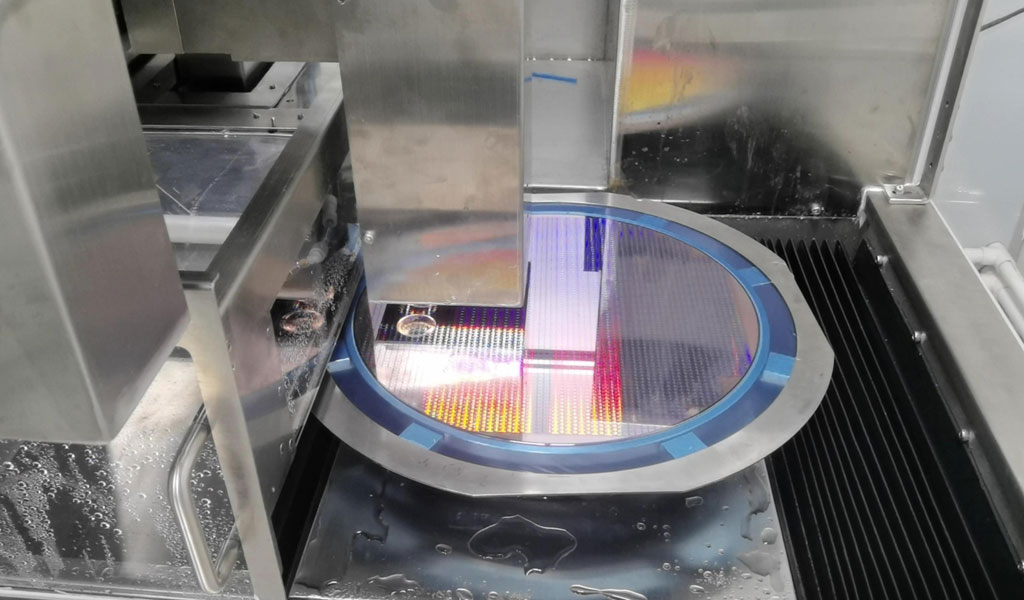

Micro Laser Cutting Solutions For Semiconductor

Be-Cu Prototype is engaged in laser micro-laser cutting services for semiconductor integrated circuits. It started the research and development of the earliest SMT template laser cutting system and process application in China in the early 21st century.

With the continuous construction of the knowledge system, the increasingly perfect technology accumulation, and the in-depth understanding of market application needs, a set of key functional components used in laser micromachining systems, standard special machines for market segment needs, supporting automation systems and Forward laser micromachining system development system for process methods.Adhering to the craftsmanship spirit of “making systems is making craftsmanship”, we have successively developed hard and brittle materials such as ceramics, aluminum & copper & ceramic PCB circuit substrates, FPC, SMT stainless steel mesh plates, chip filter carriers and other lasers used in the field of semiconductor integrated circuits.

Micro laser cutting production line, the process covers laser cutting, laser grooving, laser scribing, laser etching, laser marking, laser blind engraving, laser welding, etc.

Be-Cu Prototype has been rated as a national high-tech enterprise, a private technology enterprise in Guangdong Province, a high-end medical device manufacturing system and process engineering technology research center in Dongguan, a science and technology research and development center in Chang’an Town, and a specialized and special new enterprise in Dongguan. It has IS09001, Quality system certifications such as IATF16949 and IS013485 are gradually growing into a one-stop semiconductor integrated circuit micro laser cutting solution provider and innovative service complex in the industry.

Micro Laser Cutting Solutions For Precision 3C Structural Parts

Be-Cu Prototype Co. is engaged in the development of laser micro-laser cutting systems for computers, communications and consumer electronics products.

It began the research and development of the earliest glass and SMT template laser cutting systems and process applications in the early 21st century.

With the continuous construction of the knowledge system, the increasingly perfect technology accumulation, and the in-depth understanding of market application needs, a set of key functional components used in laser micromachining systems, standard special machines for market segment needs, supporting automation systems and Forward laser micromachining system development system for process methods. We have successively developed various types of laser cutting, drilling, grooving, scribing, etching, three-dimensional engraving, and welding for precision 3C structural parts based on direct-drive mobile dual-drive, single & double rotating axis multi-axis precision motion platforms. , marking and other laser micro-laser cutting production lines.

Online Cooperate With Electronic Parts Laser Cutting Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision laser cutting and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.