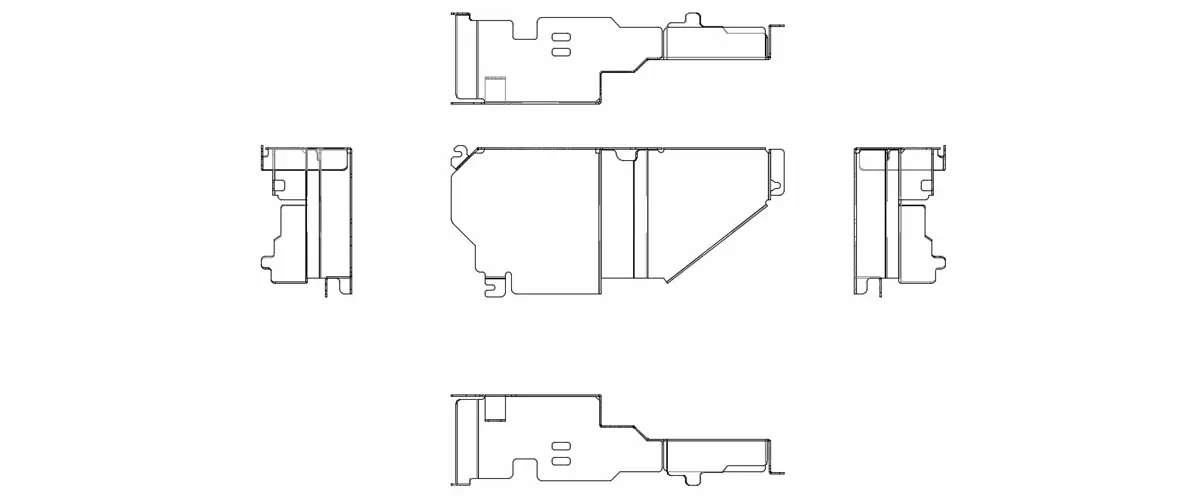

3D Printer Scanning Module Support

- Product Name: Electrolytic Plate

- No+Color:Custom

- Surface Treatment: Customized

- Product Material: Galvanized Sheet Metal Plate

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Sheet Metal

- machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: 3D Printer

- Production Process: Laser Cutting And Sheet Metal

- Size: According To Customer’s Drawings

High-Quality Sheet Metal Manufacturing 3D Printer Scanning Module Support Connecting Plate

The electrolytic plate sheet metal workpiece shown is BE-CU COM is a support connecting plate designed for printer scanning module. This article mainly shows the parameters, process and some common problems of the component from various aspects. BE-CU. COM has 13 years of design, development and production of precision metal structures of intelligent terminals.This component has the following characteristics:

- Resistance to oxidation and corrosion;

- Multiple bending and edge clamp hole design can make the product meet more internal structure assembly requirements;

- High precision;

- Non standard customized products can accept the update of the model number and adjust the latest product functional requirements in a timely manner;

Note: At the bottom of the page, there are more detailed photos of the product to show the product features of the electrolytic plate sheet metal parts.

The Process Of Sheet Metal Manufacturing 3D Printer Scanning Module Support Connecting Plate

| Serial Number | Process | Process Description And Precautions |

|---|---|---|

| 1 | Laser cutting | Set the computer through the |

| 2 | Deburring | Remove the thorns or burrs , and the burr height must be controlled below 0.2mm ; |

| 3 | Bending | The angle error is controlled within 0.3 °, and attention should be paid to the bending skills of the tail of the metal plate to avoid deformation; |

| 4 | Quality Inspection | Comprehensive inspection of quality requirements such as dimensional errors and surface scratches of finished products; |

| 5 | Package | The exclusive packaging solution for electrolytic plate sheet metal parts can effectively avoid collision deformation and surface ; |

The Advantages Of Sheet Metal Manufacturing 3D Printer Scanning Module Support Connecting Plate

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Sheet Metal Manufacturing 3D Printer Scanning Module Support Connecting Plate

| Product Size | 217*56*97mm | Expand Size | 179*261.5*1mm |

|---|---|---|---|

| Product Material | SECC | Material Thickness | 1mm |

| Surface Treatment | none | Processing Difficulty | generally |

| Size Tolerance | ±0.3mm | Angle Tolerance | ±0.5° |

The Common Problems Of Sheet Metal Manufacturing 3D Printer Scanning Module Support Connecting Plate

Most of the products used in electrolytic plate sheet metal parts on the market are no longer surface treated?

This is because the electrolytic plate product itself has a certain anti-corrosion performance due to the properties of the material. Most electrolytic plate sheet metal parts on the market are the internal structural parts of the product. If the appearance and outdoor placement are not considered, the surface treatment of the product can not be carried out. .

Be-cu.com has 13 years of experience in sheet metal manufacturing and production , especially in the manufacturing of non-electrolytic sheet metal parts. The purpose is to promote the manufacturing and upgrading of China’s precision sheet metal processing.

What is the biggest difference between electrolytic sheet metal parts and cold rolled sheet metal parts?

The biggest difference between the two is their anti-corrosion performance. Although they have been sprayed on the surface, the electrolytic sheet metal parts have better anti-corrosion performance

due to the existence of the galvanized layer , even if the surface is subjected to impact. Or after being scratched , it will still have a certain degree of corrosion resistance, while the cold-rolled sheet metal parts are more likely to be corroded after the surface is slightly worn .

Therefore, in general use, if cold-rolled sheet metal parts are used instead of electrolytic sheet metal parts , the designer will add a surface treatment process to add an extra layer of protective film to the surface of the product to strictly protect the product. .

The Detail Of BE-CU Laser Cutting Company

BE-CU.COM Laser Cutting provides services to a wide network of industries and markets. BE-CU is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.We use large format industrial laser cutting machines that are extremely precise with up to .001” tolerance. Not only we cut and engrave your project, we are ready to answer any questions you may have about the process and give you expert advice.

So, reach out even if you’re unsure of your specific need or if you think you may require a different type of manufacturing service(as laser cutting medical parts). Laser cutting service by BE-CU makes ordering your parts simple. Just upload your CAD files onto the platform for an instant price and lead time. Our mission is to save engineers’ time for value-adding activities.

-

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

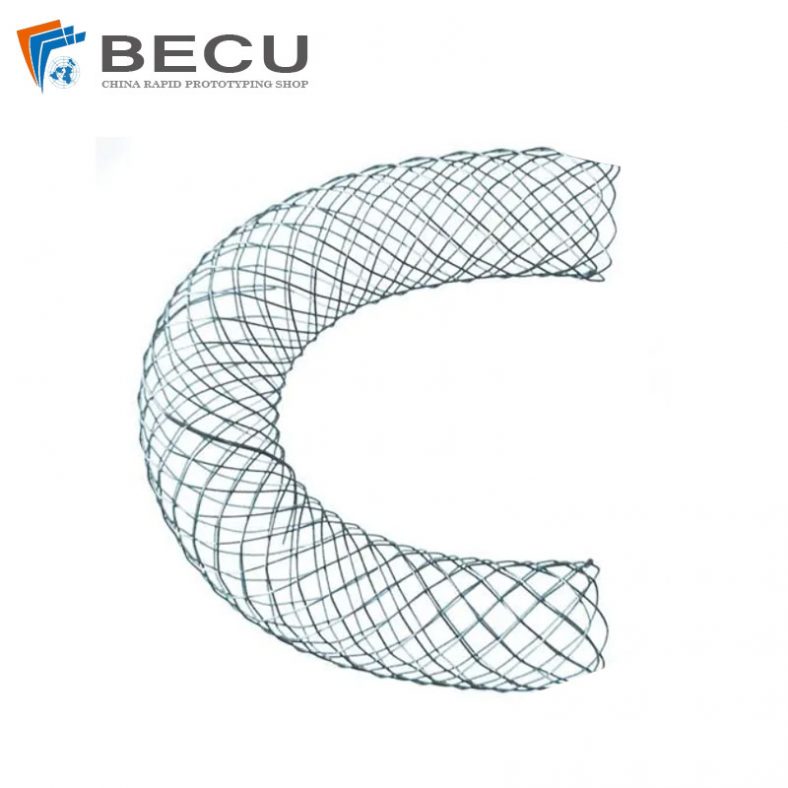

Laser Cut Nitinol Stent For Bile Duct

-

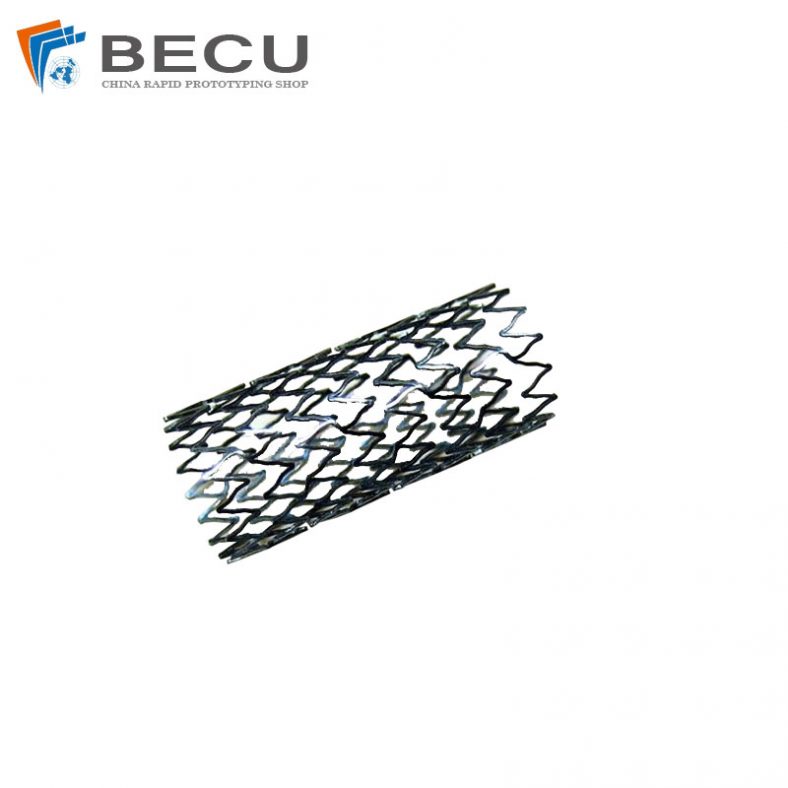

Stents For Carrying Valves And Venous Valve Replacement Devices

-

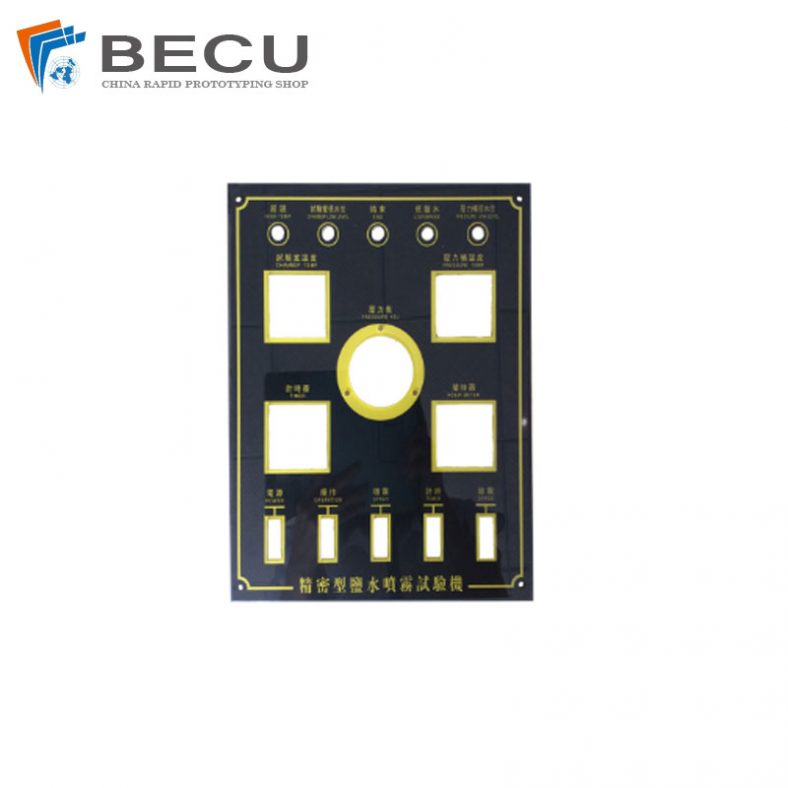

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

Acrylic Laser Cut Signs

-

Acrylic Laser Cut Earrings